Nice, I use ER20 collets in my CNC router but I yet to make a holder for the collets.here is another one for the group. @David might get some use

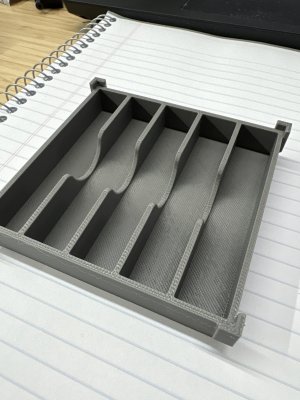

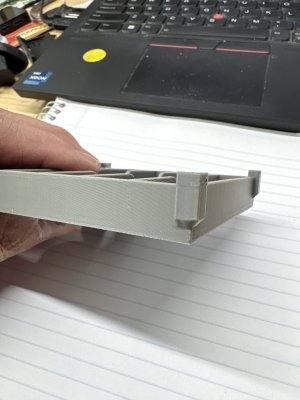

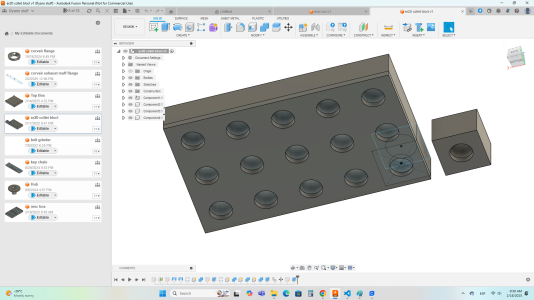

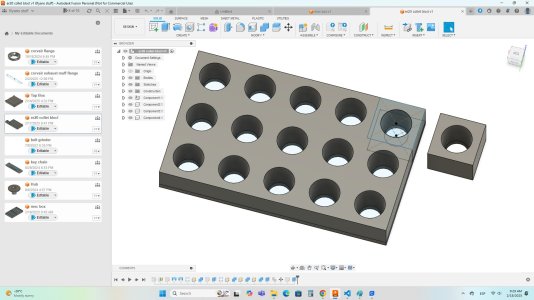

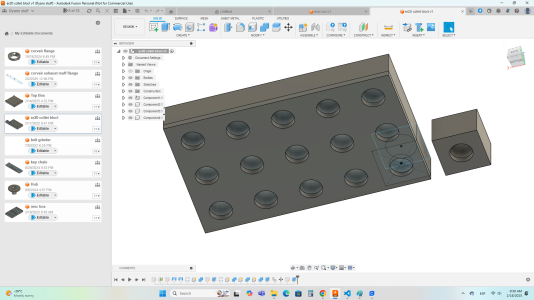

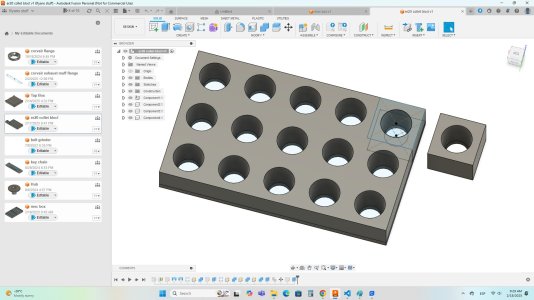

collet block for er20 collets, like used in the 2.2kw spindles, attached is the block with 15 spaces and a single block with only 1 space

I print it upside down, and select no top layer, saves print time & filament

View attachment 60072

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tips/Techniques Show your shop related 3DP

- Thread starter PeterT

- Start date

Tips/Techniques

You mean the 'top' side we are seeing with collets was the plate side? Do the collet holes have a bottom surface or essentially the collet hole goes right through the storage block?I print it upside down, and select no top layer, saves print time & filament

Is the block itself 'shelled' inside of all surfaces?

i modeled it in fusion as a solid block, you can print it just like it is, it will print a solid layer for the topside and the bottom side, with whatever infill you select. I didnt model it hollow with walls, figured it was easier to let the slicer do that work for me. By flipping it over so that the top of the block is on the bottom of the build sheet and omitting the top layer, you can make the block as hollow as you like by adjusting the infill and omitting the bottom layer, it is quite stiff as i printed it with i think 15% infill

here are screenshots of the models

here are screenshots of the models

Ah I getcha now. For whatever reason I made a floor to the collet so I was having trouble visualizing printing inverted without using supports

(ER16) I made the rack outline to fit a box & lost track of the fact I only own 1/3 as many collets. Should have made it half the size & left room for tooling.

(ER16) I made the rack outline to fit a box & lost track of the fact I only own 1/3 as many collets. Should have made it half the size & left room for tooling.

Printing one of these boxes now 🙂designed/printed this little tap box last night, it could be stacking or just with the lid, each slot is 80mm x 15mm x 12mm deep

included are the stl's if anyone wants to print one, or ten

View attachment 59834

Slicer says 50 mins. So far the slicer has over estimated about 8-10%

Edit: 49 minutes including warm up and cleaning at the end.

Last edited:

That occurred to me in some other prints in a DUH moment. Why am I bothering? Shelling saves material in typical injection molded plastics but 3DP has a better trick - fill the void space with many choices of infill geometry, density, thicknesses... all that with just a button click in Slicer.figured it was easier to let the slicer do that work for me.

I can't comment on the adjustability of the design but @phaxtris likely can as it's his excellent design.Damn that looks COOL @David! Love the stackability. How easy is it to resize and change the number of slots?

Does the plastic handle the odd spray of oil?

As far as durability goes, all the 3DP stuff I have in the shop seems to hold up fine to whatever I throw at them

Smart idea.I simply scaled in X for narrow slots, like for 1/4” taps was 50%. I did some at 75% as well. I enlarged in both directions for larger taps X and Y. Z will make the slots deeper. I did all this in slicer.

Pierre

Rather than a blade brush per se, I used some flat copper braid about 3/8" wide. Its just a tube made from fine copper wires and it does a great job.The stamped metal plate that attaches to my drop down saw is (I think?) a glorified barrier to keep shavings piling up around the bearings. That aspect is fine enough, but its an ill-fitting contraption. Its about 3mm stamped metal which requires custom M6 flathead screws. By custom I mean they were buzzed down with a disc grinder at the factory real purdy like. The plate is also too long so it bottoms out on the casting bed & out of adjustment range for shut off switch. So I just jigged the dimensions a bit & this is what you see.

Now that the plate is in position, I started to stare at the blade brush you can see just underneath. So that's the next potential mod. Maybe harvest the ends off a common wire brush & have one on either side of blade which would do a lot to dragging the swarf in behind the pulley cover. Its a bit tight in there but TBC.

Back on the topic of the thread, I have a suggestion for STL/STEP/IGES/F3D sharing that does not involve money.

Take a look at GrabCAD: https://grabcad.com

I have been using this for about 5 years. It is a community oriented towards engineering models, rather than pretty critters and toys.

If there is some consensus here, I will create a CHMW group account, which will centralise where the models are stored. Only original content should be posted (no remixes or copied models).

Thoughts?

Take a look at GrabCAD: https://grabcad.com

I have been using this for about 5 years. It is a community oriented towards engineering models, rather than pretty critters and toys.

If there is some consensus here, I will create a CHMW group account, which will centralise where the models are stored. Only original content should be posted (no remixes or copied models).

Thoughts?

Turns out I've had a GrabCad account for some time, I should use it more. I do see it has a a 3DP sub-category which is good. But wouldn't some of the other dedicated 3DP sites have a whole lot more? Or do they have other restrictions or costs or other disadvantages? (I've only had a quick look in some 3DP sites, aside from Bambu which seems to be kind of hooked up to the back end of Studio/Slicer I really have no understanding of other sites & services).

My last little build was for a small single pole relay to be used with my current lathe arduino project. 2 relays fit in, then 3 holes for wiring, only used one. Recessed lid and #4 x 3/8 wood screws.

www.tinkercad.com

The relays I use, universal is my go to for arduino stuff. Volker is great to deal with and he is in the GTA, so no boarder issues. He helped me with some programming a couple years back with one of their canaduino boards.

www.tinkercad.com

The relays I use, universal is my go to for arduino stuff. Volker is great to deal with and he is in the GTA, so no boarder issues. He helped me with some programming a couple years back with one of their canaduino boards.

www.universal-solder.ca

www.universal-solder.ca

Login - Tinkercad

2 pcs. Relay Module 12V for loads up to 10A / 250V (5V logic level input)

With LEDs for power supply and activity. The relays require 12V operating voltage.

The amount of stuff on grabcad is amazing. I recommend it to anyone building something in the 3d. Down to components or even connectors. Grabcad is more for actually 3d drawings of devices. Try a look on thingiverse, printables, thangs, cults and others for items to print directly.Turns out I've had a GrabCad account for some time, I should use it more. I do see it has a a 3DP sub-category which is good. But wouldn't some of the other dedicated 3DP sites have a whole lot more? Or do they have other restrictions or costs or other disadvantages? (I've only had a quick look in some 3DP sites, aside from Bambu which seems to be kind of hooked up to the back end of Studio/Slicer I really have no understanding of other sites & services).

View attachment 60154