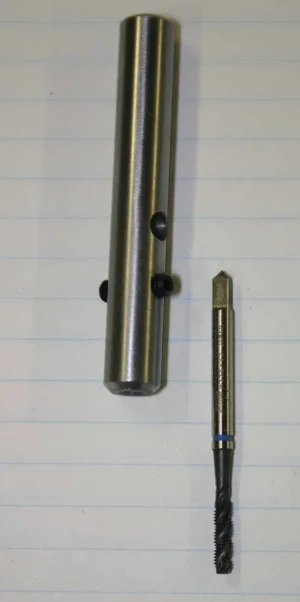

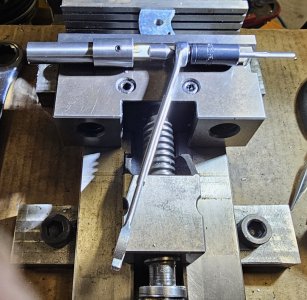

This is my favorite tap follower. Someday I'll make an even better one but I can't really complain about this one. It has always worked just fine. It does require taps with a 60 degree center or a 60 point at the drive end. You just use a regular tap wrench or an open end wrench on the top of the taps.

For taps that don't have a center you can either drill a center yourself, or use a tap driver with a square drive socket cap that has a center.

Here are my tap drivers. They are worth their weight in gold and I highly recommend them. I have not yet encountered a tap between a #4 and 1/2" that one of them doesn't fit. Smaller and bigger prolly need something else anyway.

Lisle LI70500 Tap Socket Set

Here are some square drivers. They are not the same as mine but can't imagine it would make any difference. They just need to have a 60 degree center drilled into the top of them for the follower to fit into.

3 PC Square Drive Socket Caps, Hex 7/16", 9/16" & 3/4" with 1/4", 3/8" & 1/2" Drives

Note that the tap drivers have a fairly tight fit with an internal retainer. The assembly is quite stiff so you don't need to worry about any misalignments stacking up. Basically the tap, tap socket, and driver act as one unit that can be centered and held vertical directly by the tap follower mounted in a drill press or mill or lathe. It works really well.