The down side of Alibre is that each time they do a yearly 'enhancement' or 'bug fix' they change the revision.

Backward in-compatibility is an unavoidable result of things getting old. True for computers and software too.....

The down side of Alibre is that each time they do a yearly 'enhancement' or 'bug fix' they change the revision.

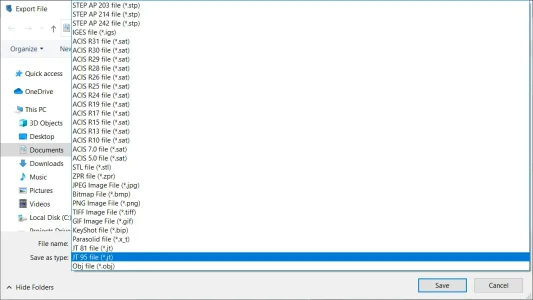

That's why my Office 2010 can still read office documents and spreadsheets etc. created by newer versions? The decision to not have a "Save As Version" with the potential loss of information is always possible and much as people might not like Microsoft they've had that feature for a really long time. Go into Alibrev and the Export file and look at all the different revisions for other software packages that they support.Backward in-compatibility is an unavoidable result of things getting old. True for computers and software too.....

That's why my Office 2010 can still read office documents and spreadsheets etc. created by newer versions?

CNC - Never (point SW Maker)

Job Out - Unlikely (point SW Maker. TBC, possibly DXF or other 2D formats still allowed which works for laser/water cutting)

Stress & Heat Transfer - Prolly (limited to nil in SW-Maker)

Nice drawings like yours - Yes (point SW Maker)

Sectioning & interference - Yes (point SW Maker)

2D Work Drawings - Must have (as above point SW Maker)

3D Printing - Must have (according to link yes, but for some reason I thought no, .STL was a blocked format. Maybe I'm mixed up with .STEP or .IGES or something else)

When I first trialed fusion 360 I was also using solidworks at the same time. I just could not adapt to fusion. Things seemed backwards compared to what I was used to. Since I knew I would not be able to have access to solidworks for much longer I needed a plan. I just stopped using solidworks and switched 100% to fusion. I downloaded some plans for steam engines (Elmer's?). From that point I would just pick one and model it 100% in Fusion. When issues arrived I would google the problem. No matter what issue you have someone else has already solved it.Just some more thoughts Gerrit. Could it be that your learning difficulties were imposed by Fusion itself and not necessarily 3D CAD itself?

To be frank, I was a fighter jet pilot in Catia. I could literally do anything. But I'm still struggling to learn Fusion 360. It simply isn't intuitive to me. Maybe you experienced Fusions barriers in a different way. But perhaps it is Fusion itself that is at fault and not where we each came from.

Regardless, I am determined to learn Fusion because it's the only affordable tool out there that can do what I need it to do.

One problem I had was that I would get stuck part way through a drawing because I did something in a poor older and deleted something that I needed to reference for a later dimension. Turns out you can roll back the slider and temporarily restore the deleted reference point. Saved me a lot of restarts.

Yeah, I know I'm getting old too.....My sometimes feeble attempts at humour are not always well thought out. It was really a shot at you not your computers or your software. I just added that for the "huh?" effect.

I did the same sort of thing with Alibre when I first started. I already had my Gingery Lathe made from castings etec. But for an exercise I took the 2D drawings and sketches from his book. Then from the 3D part even able to recreate the 2D drawing. Sometimes it's easier to learn something by drawing something that already exists than to start from scratch for something that doesn't.Crankshaft for the radial engine. I originally drew this in solidworks. Out of curiosity I imported the assembly into Fusion 360 to see if it would work. It worked flawlessly. This surprised me because solidworks won't even import a newer version of something drawn in it's own software. I will probably redraw it in Fusion 360 to keep things consistent.

I find fusion to be easy to work with from scratch for anything that was designed to be made on a manual mill. Same with solidworks.I did the same sort of thing with Alibre when I first started. I already had my Gingery Lathe made from castings etec. But for an exercise I took the 2D drawings and sketches from his book. Then from the 3D part even able to recreate the 2D drawing. Sometimes it's easier to learn something by drawing something that already exists than to start from scratch for something that doesn't.

I find fusion to be easy to work with from scratch for anything that was designed to be made on a manual mill. Same with solidworks.

Sorry no online lessons. I could probably show you how to get by if you lived in my part of Canada. Maybe try drawing one of the steam engines I mentioned and then figure out what part you are stuck on. They maybe I could give better advice.Do you give on-line lessons?

Not kidding...

Maybe try drawing one of the steam engines I mentioned

At one point in your life walking was beyond your ability, but one step at a time......WAAAAY beyond my ability right now......

At one point in your life walking was beyond your ability, but one step at a time......

As for the comment about fusion being better for stuff you're going to manually machine That's all in how you start modeling. In your head, you're already machining the part and that comes out in how you model it.