Rubbing is a very good choice of words @RobinHood.

I checked out the concept that @John Conroy suggests. As I expected based on what I did yesterday, removing the pins did nothing. The cam is already down as far as it can go.

But, then again, it is down as far as it can go!!!!! That also struck me as odd. What is the point of a bottom position on the cam if that is as far as it can go? On a hunch, I tried lifting the clutch a smidge. The noise dramatically reduced!!! But did not go away completely. I can lift it with varying degrees of effectiveness but none are as effective as totally disengaging it. I didn't get too aggressive with lifting it because I didn't want to ruin the tops of the castellations on either half.

So ya, rubbing is a great description. It must be rubbing somewhere. Perhaps even on the top and bottom interface instead of the teeth. If either one isn't perfect and wobbles a bit like a swashplate, it may be rubbing or kissing at the high points.

I am waiting for a new timing belt anyway, so I will leave it as is for a while and use it in low speed to assess the other parts of the mill. When the timing belt arrives, I'll take the top off to change it and then also use the opportunity to have a real good look at the clutch castellations. I inspected them previously, but obviously not well enough.

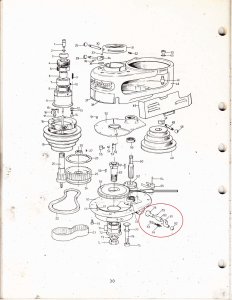

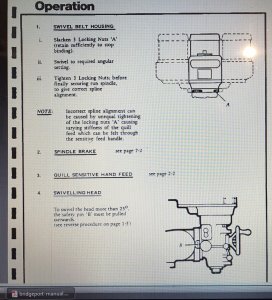

In the meantime, I'll take another look at how the clutch disassembles and what parts are involved so I can be ready to remove, repair, or replace as appropriate.

Btw, my steel epoxy repair of the timing belt pully is shining up very nicely from rubbing on the timing belt. I was worried about that and left the pulley flange off intentionally so I could watch it for a while. I can put it on anytime because I bought some allen head machine screws to replace the originals with so access with a small Allen wrench is a piece of cake.

I checked out the concept that @John Conroy suggests. As I expected based on what I did yesterday, removing the pins did nothing. The cam is already down as far as it can go.

But, then again, it is down as far as it can go!!!!! That also struck me as odd. What is the point of a bottom position on the cam if that is as far as it can go? On a hunch, I tried lifting the clutch a smidge. The noise dramatically reduced!!! But did not go away completely. I can lift it with varying degrees of effectiveness but none are as effective as totally disengaging it. I didn't get too aggressive with lifting it because I didn't want to ruin the tops of the castellations on either half.

So ya, rubbing is a great description. It must be rubbing somewhere. Perhaps even on the top and bottom interface instead of the teeth. If either one isn't perfect and wobbles a bit like a swashplate, it may be rubbing or kissing at the high points.

I am waiting for a new timing belt anyway, so I will leave it as is for a while and use it in low speed to assess the other parts of the mill. When the timing belt arrives, I'll take the top off to change it and then also use the opportunity to have a real good look at the clutch castellations. I inspected them previously, but obviously not well enough.

In the meantime, I'll take another look at how the clutch disassembles and what parts are involved so I can be ready to remove, repair, or replace as appropriate.

Btw, my steel epoxy repair of the timing belt pully is shining up very nicely from rubbing on the timing belt. I was worried about that and left the pulley flange off intentionally so I could watch it for a while. I can put it on anytime because I bought some allen head machine screws to replace the originals with so access with a small Allen wrench is a piece of cake.