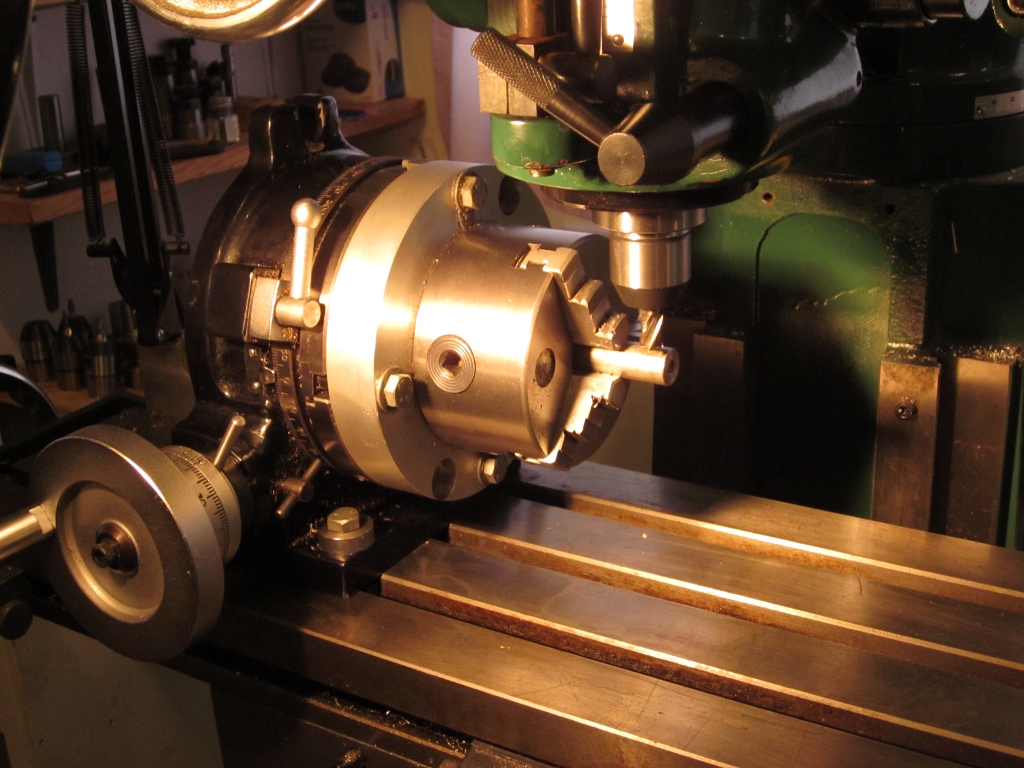

Ah, well, I put on the locks so that it drags just a bit (per BP manual) and then always rotate the table INTO the cutter. Works great . The biggest piece is milled out of solid so far was this:

The slug you see in the center of the ring is what I machined out of the stock. Stock dimensions were OD 10” by 2” thick, 316 stainless steel. The left-over slug is 5.25” by 2” thick.

All done with a 1/2” HSS end mill and the 12” RT.

The slug you see in the center of the ring is what I machined out of the stock. Stock dimensions were OD 10” by 2” thick, 316 stainless steel. The left-over slug is 5.25” by 2” thick.

All done with a 1/2” HSS end mill and the 12” RT.