I was also wondering about just buying the sensor and making my own mounts.

The mounts they provide are so rinky dink I can't really imagine using them anyway.

I was also wondering about just buying the sensor and making my own mounts.

I asked Nicholas if he'd read this thread and perhaps answer some questions, but I'm sure he is busy and the UK time zone would also be an issue...I was also wondering about just buying the sensor and making my own mounts.

No.Does he have any sort of web site/presence? I want to read more about these.

You suck...He also has a minty RF45 that I may try and weasel out of him.

Well not so much as he wasn't willing to sell the mill.You suck...

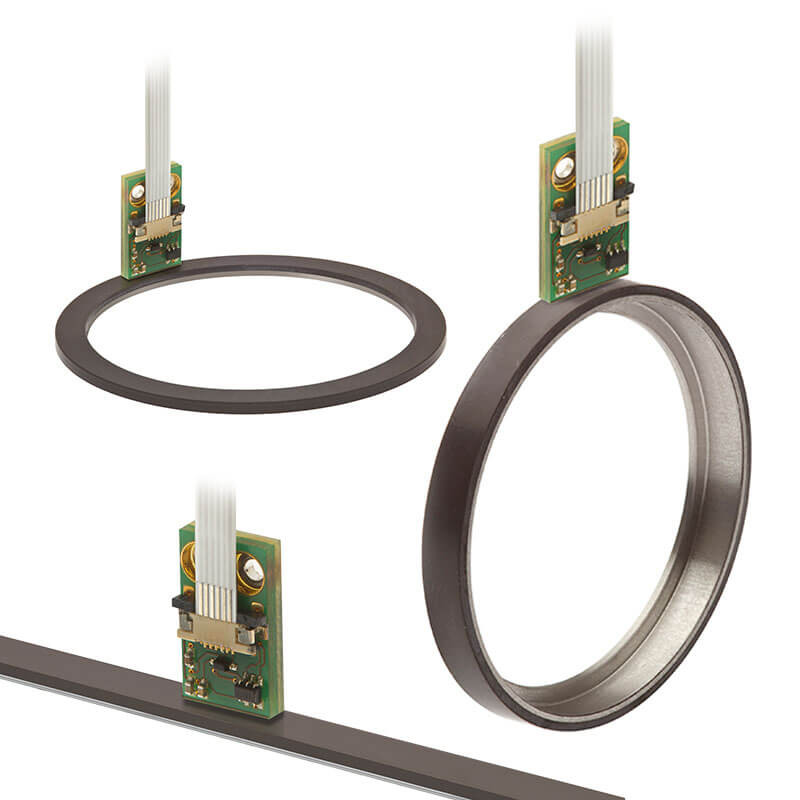

Maybe this?I really like the size, that being said I would prefer to get the tape and roll my own PCB that has regular quadrature output. My ELS has provision for generic quadrature output DROs. Can someone point me towards a source for the magnetic tape?

This looks like it might work:Maybe this?

They stipulate that you have to tell them if you want the aluminum extrusion otherwise it's tape and reader only.

If you will wait a bit I'll see if we can organize a group project to make pcbs with 2 or 3 options for connectionsI really like the size, that being said I would prefer to get the tape and roll my own PCB that has regular quadrature output. My ELS has provision for generic quadrature output DROs. Can someone point me towards a source for the magnetic tape?

that is 5mm pitch and provides lower resolution readingThis looks like it might work:

The AS5311 also appears to have quadrature output, so that is one option for a reader, although I will look to see if there is something smaller and less expensive with just quadrature output and without all the extra features.

Short run PCBs are so cheap now, and there's so few components to a read head....If you will wait a bit I'll see if we can organize a group project to make pcbs with 2 or 3 options for connections

my friend with whom I collaborated on the machining calculator orders pcbs all the time and then populates them with the surface mount components so this should be very easy for him.I order PCBs all the time, so if you want help with that side just let me know. I use Altium.

You dont know what you dont know....Yeah, I'm all set up for SMT work at home as well. And I'm seeing short runs with 2 day turnarounds at ludicrously low prices now. Why didn't we do this thinking at the start of winter instead of the start of summer?

LOLWell not so much as he wasn't willing to sell the mill.

Oh and I just figured out that I was assuming 4 pin output, but I am pretty sure I need 9 because the chinese read heads use all 9 pins

the chinese read head pin outI seem to recall that not all db9 pins are used. But for compatibility, it's prolly best to use the same pinout as the Chinese DROs.

I only skimmed the datasheet, but it looks like not all 14 pins need to be used.

I certainly agree that being able to put a compact read head inside the cross-slide (and even inside the compound) is a terrific advantage - perhaps even as ground breaking as putting the tape in there.....