Nicholas Bull

New Member

Hello all, sorry I haven’t been on here sooner but the kids have been on Easter holiday, although it looks like you’ve worked most of it all out anyway!

A couple of things I will point out (torontobuilder I mentioned this in the email I sent you today) is that the ribbon cable pictured in the (I think rsi) readheads you pictured will be very hard to adapt to other types of connector.

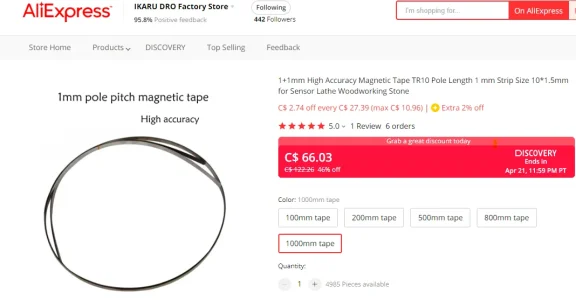

Much more important is the magnetic tape for use with the as5311, the pole length is 1mm/2mm pole pair, the tape linked to above is 2mm pole length/ 4mm pole pair. I think I found a supplier on Ali express who sells it but only in 10mm width which may be fine for your applications but was too big for mine.

The read heads I have made are incremental quadratic, and run on 3.3v.

A couple of things I will point out (torontobuilder I mentioned this in the email I sent you today) is that the ribbon cable pictured in the (I think rsi) readheads you pictured will be very hard to adapt to other types of connector.

Much more important is the magnetic tape for use with the as5311, the pole length is 1mm/2mm pole pair, the tape linked to above is 2mm pole length/ 4mm pole pair. I think I found a supplier on Ali express who sells it but only in 10mm width which may be fine for your applications but was too big for mine.

The read heads I have made are incremental quadratic, and run on 3.3v.