DPittman

Ultra Member

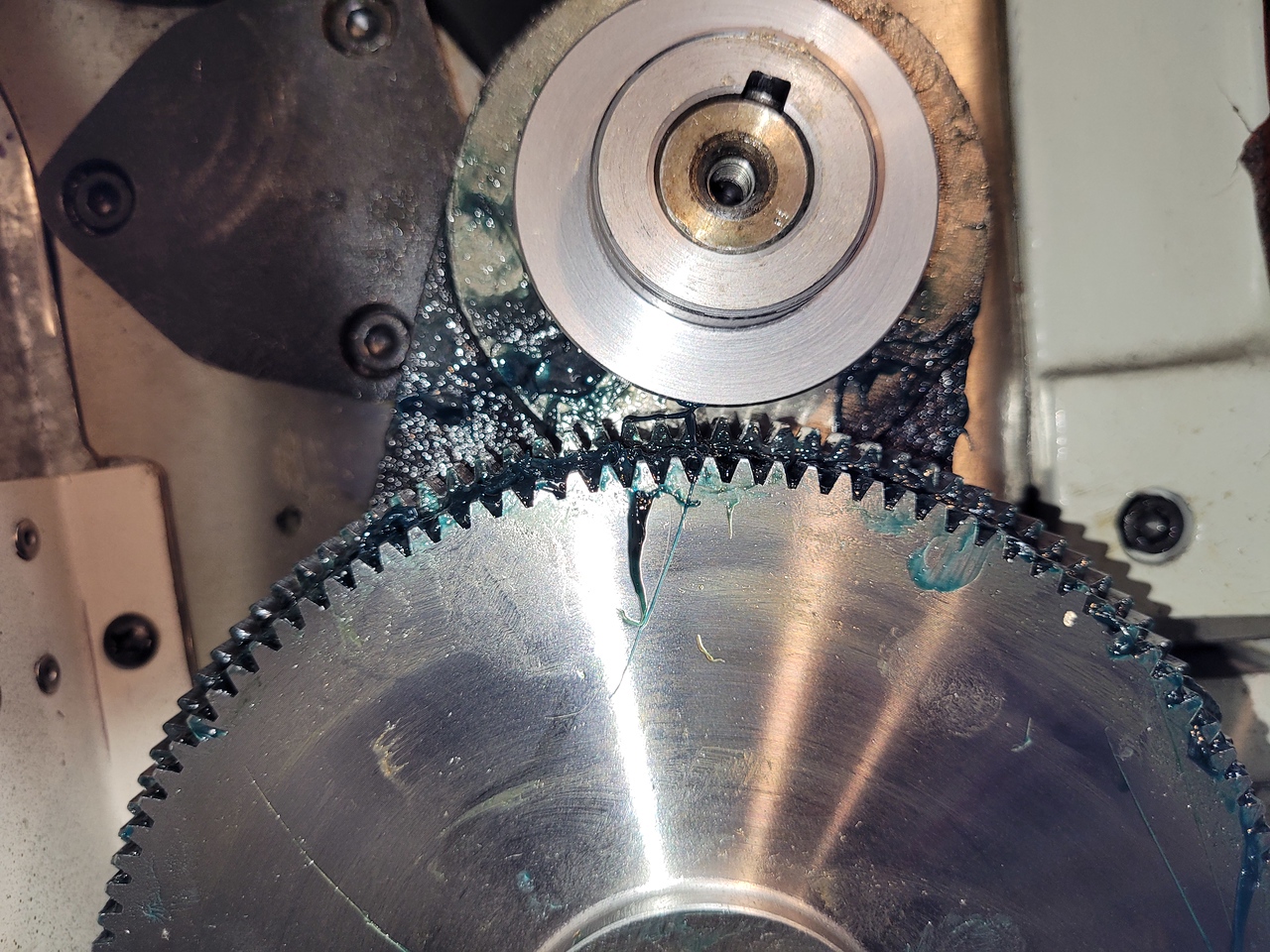

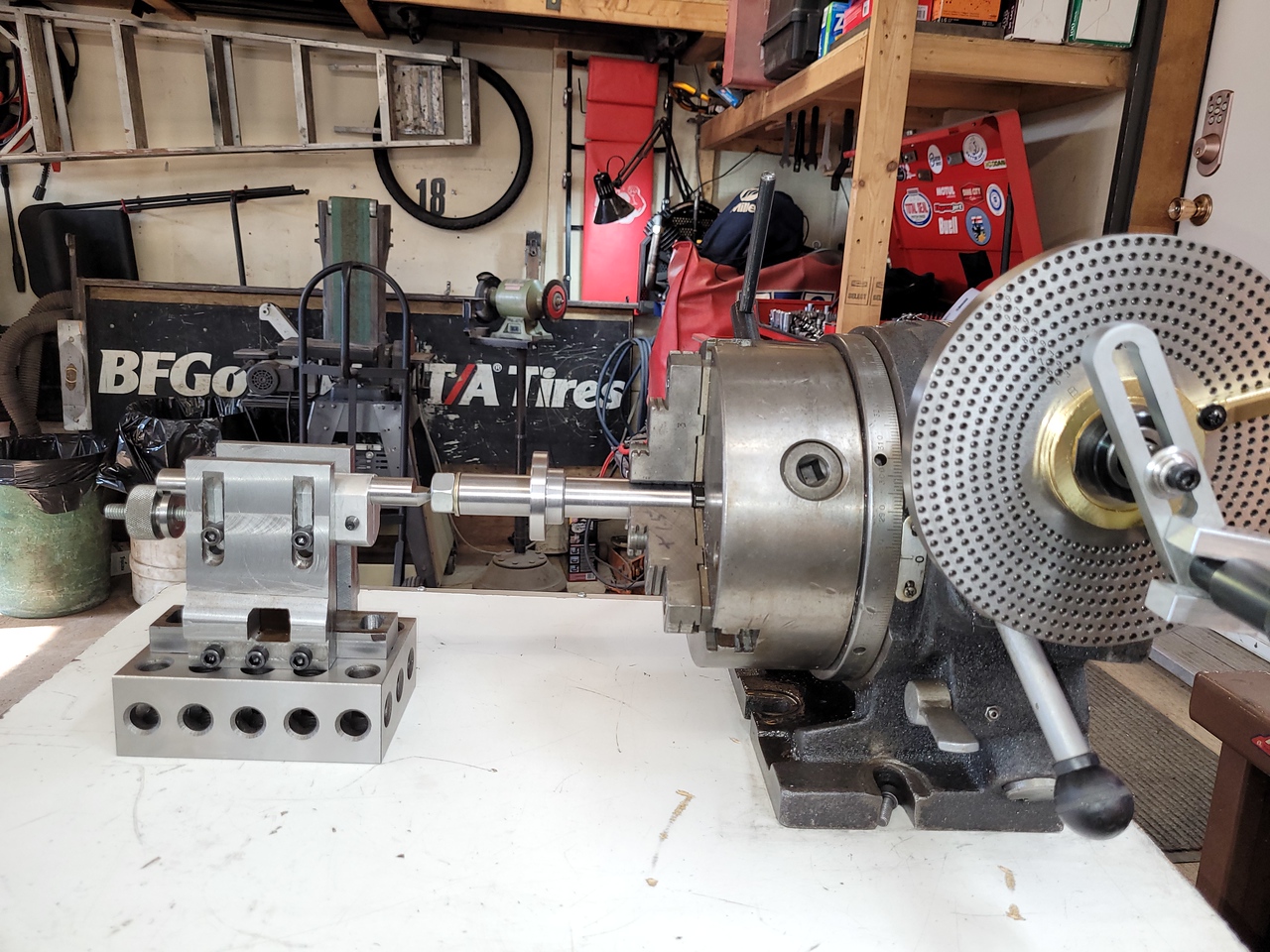

Looks like you're all ready to go! After successfully cutting those gears, you'll be looking for more to do.The gear blanks for the 36 and 42 tooth gears are done. It will probably be a month before the cutter arrives.

View attachment 32550View attachment 32552View attachment 32553View attachment 32554View attachment 32555View attachment 32556View attachment 32557View attachment 32558

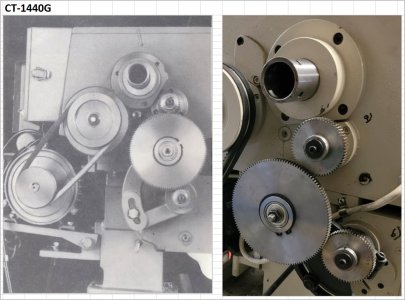

I've got a small idler lathe gear on my reverse tumbler that needs to be replaced. It has internal snap ring grooves to hold it in place which I'm not crazy about cutting and makes mounting the blank a bit different than what I've done in the past.

Keep us posted on your gears as some of us may forget😳