However it uses a 30 tooth on "a" shaft and a 60 on the "b" shaft.

One of many gear options on my lathe is also 30 on "a" and 60 on "b". It just happens that I had two 60's on mine when I took the photo.

However it uses a 30 tooth on "a" shaft and a 60 on the "b" shaft.

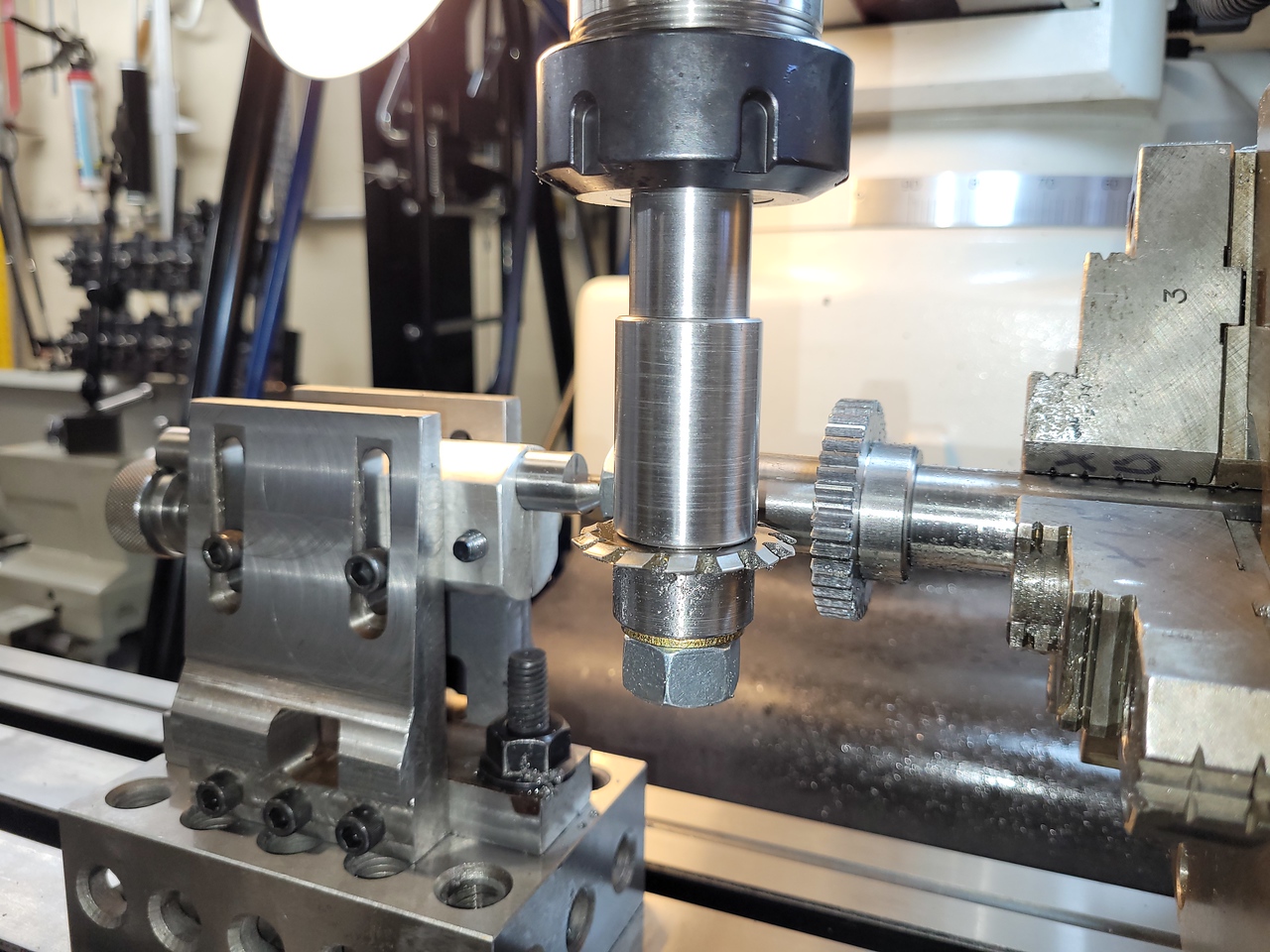

Tomorrow I'll install them on the lathe and cuts some 1.75mm threads!

I wouldn’t think cutting speed would be that much of a problem because the cutter has 14 cutters on it.

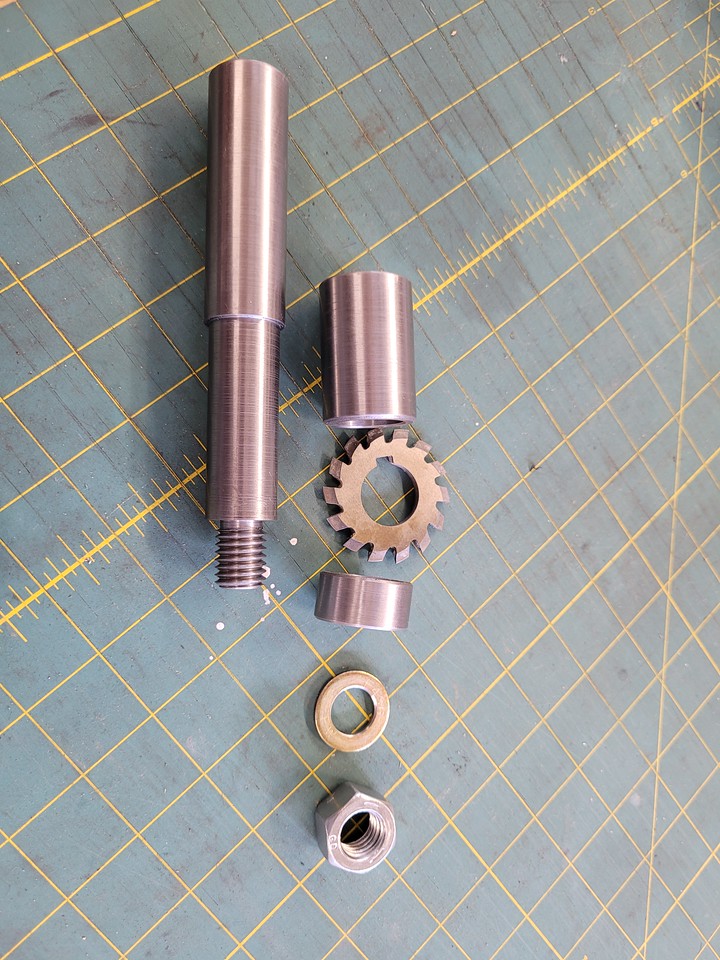

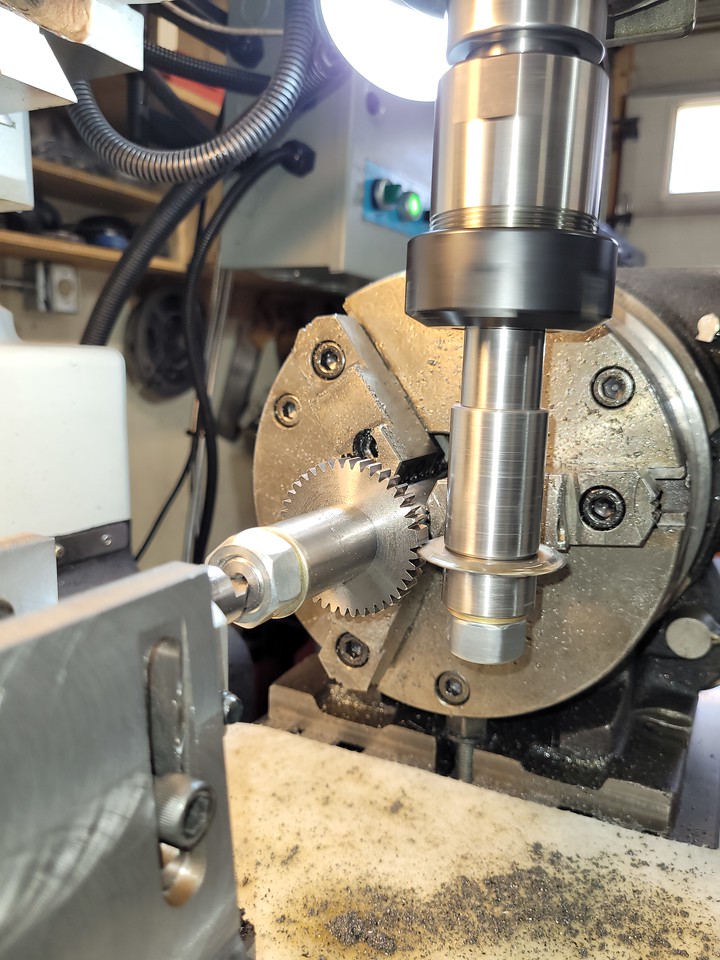

Sorry if I missed it but I didn't see that you cut in a keyway in the ar or for the gear cutter. If not, do you think it would be any better with it?OK to continue this saga, it only took 2 weeks for the gear cutter to arrive from China. I didn't review the method I used to identify the pitch of the change gears for my lathe but I found all the info online which also got me some conflicting info from different sources. I determined the gear pitch to be module 1.25. For each module there is a set of 8 cutters that will shape the teeth correctly for any gear from the smallest possible to a flat rack with an infinite number of teeth. since I needed to cut a 36 tooth and a 42 tooth gears I needed a number 6 cutter.

View attachment 33452

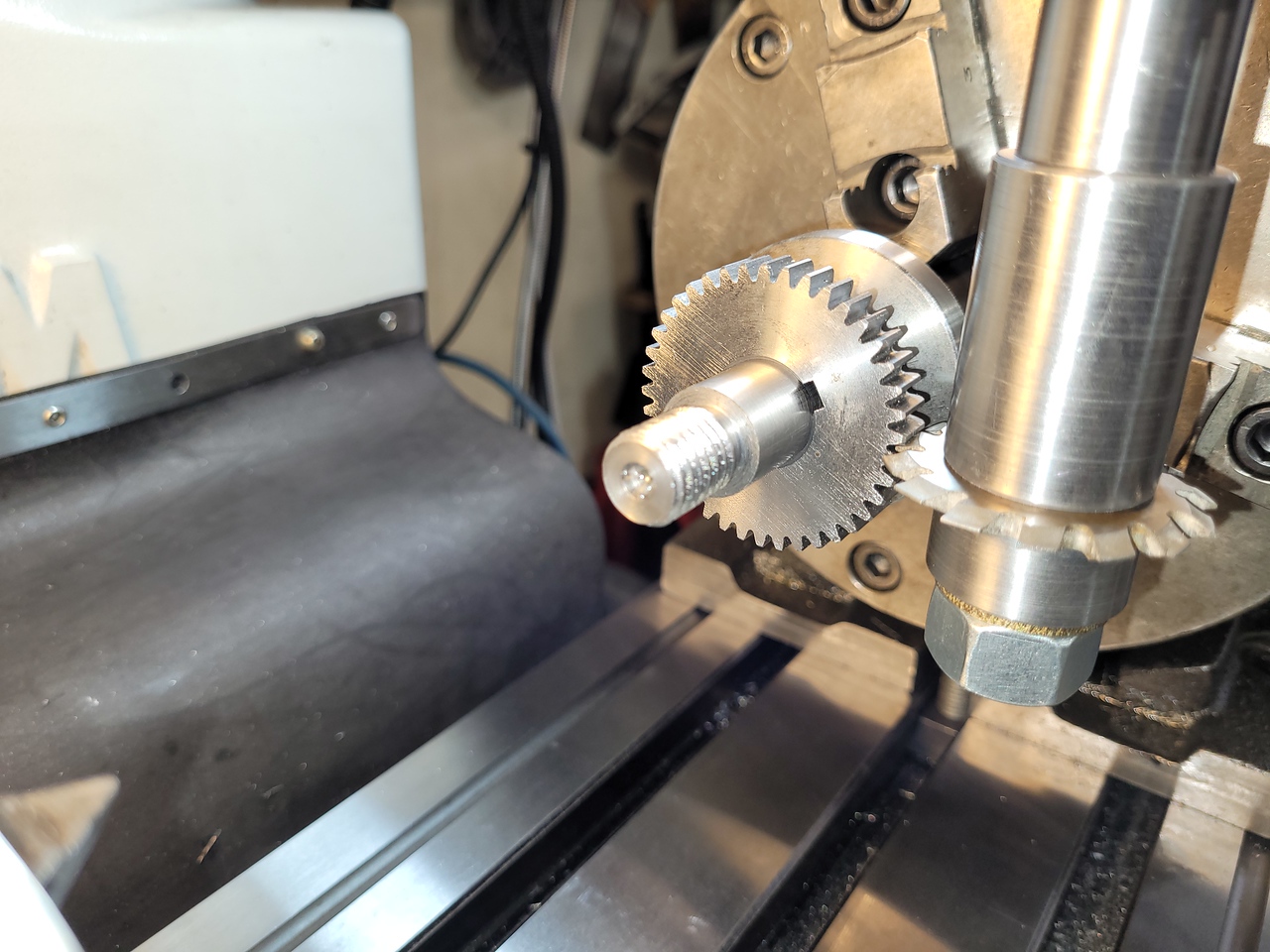

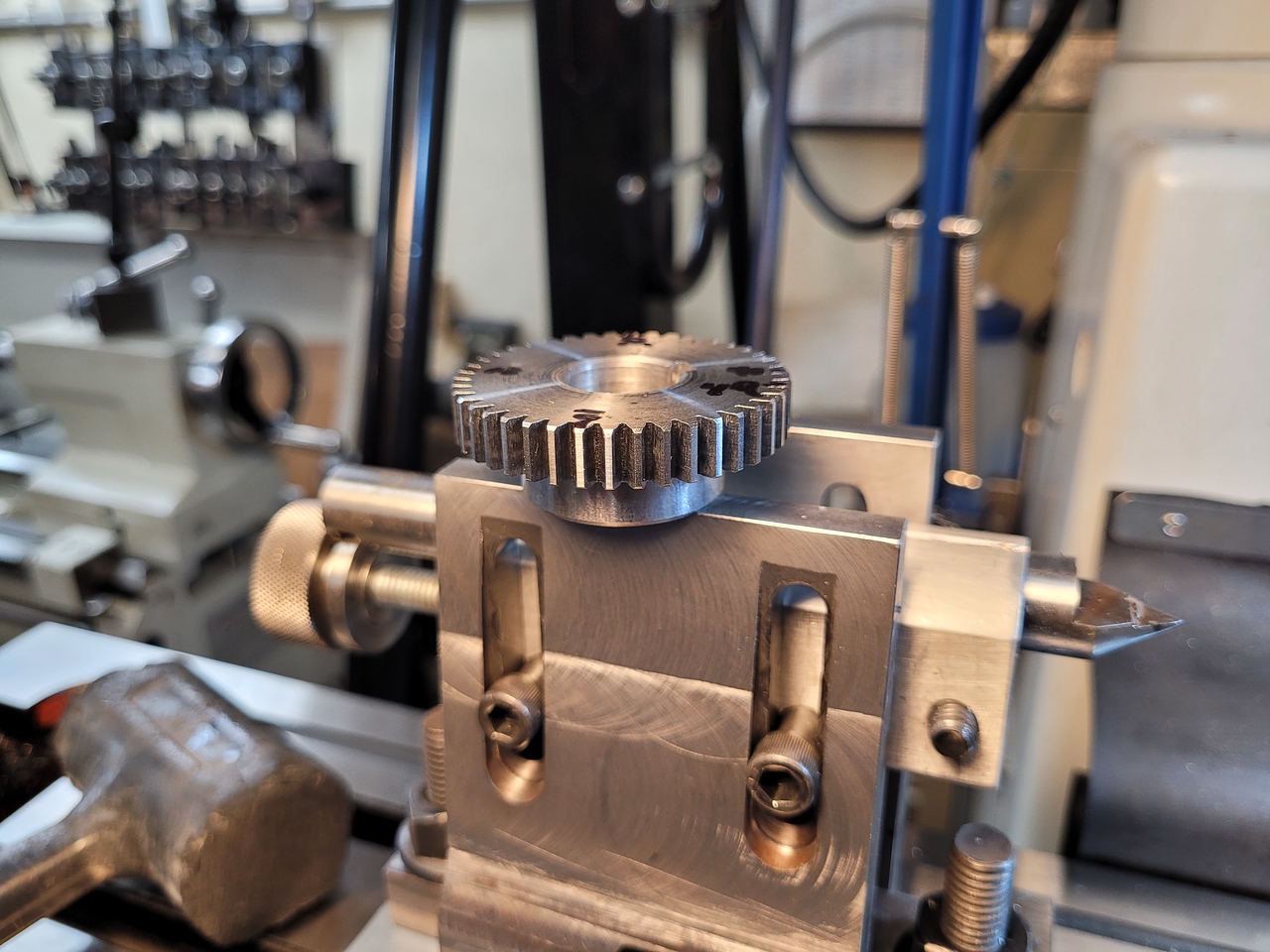

I had already made 2 arbors, one for the cutter (22mm bore) and one for the gear blank (19mm bore). They were made from 1" CRS with the large ends turned to 25mm to fit a 24-25mm ER40 collet. I test fit the cutter into one of the 40 tooth gears that came with the lathe and it seems like a good fit.

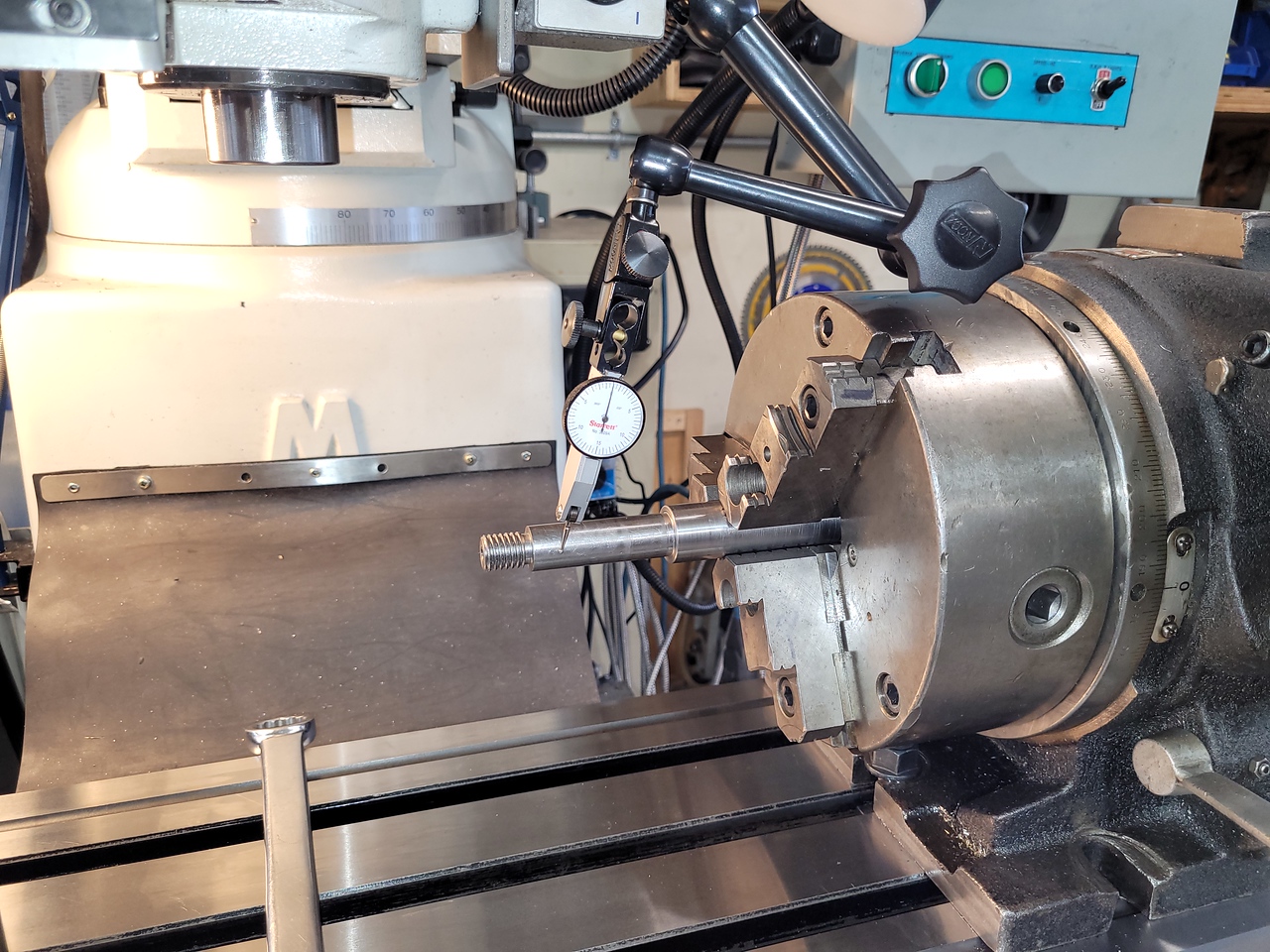

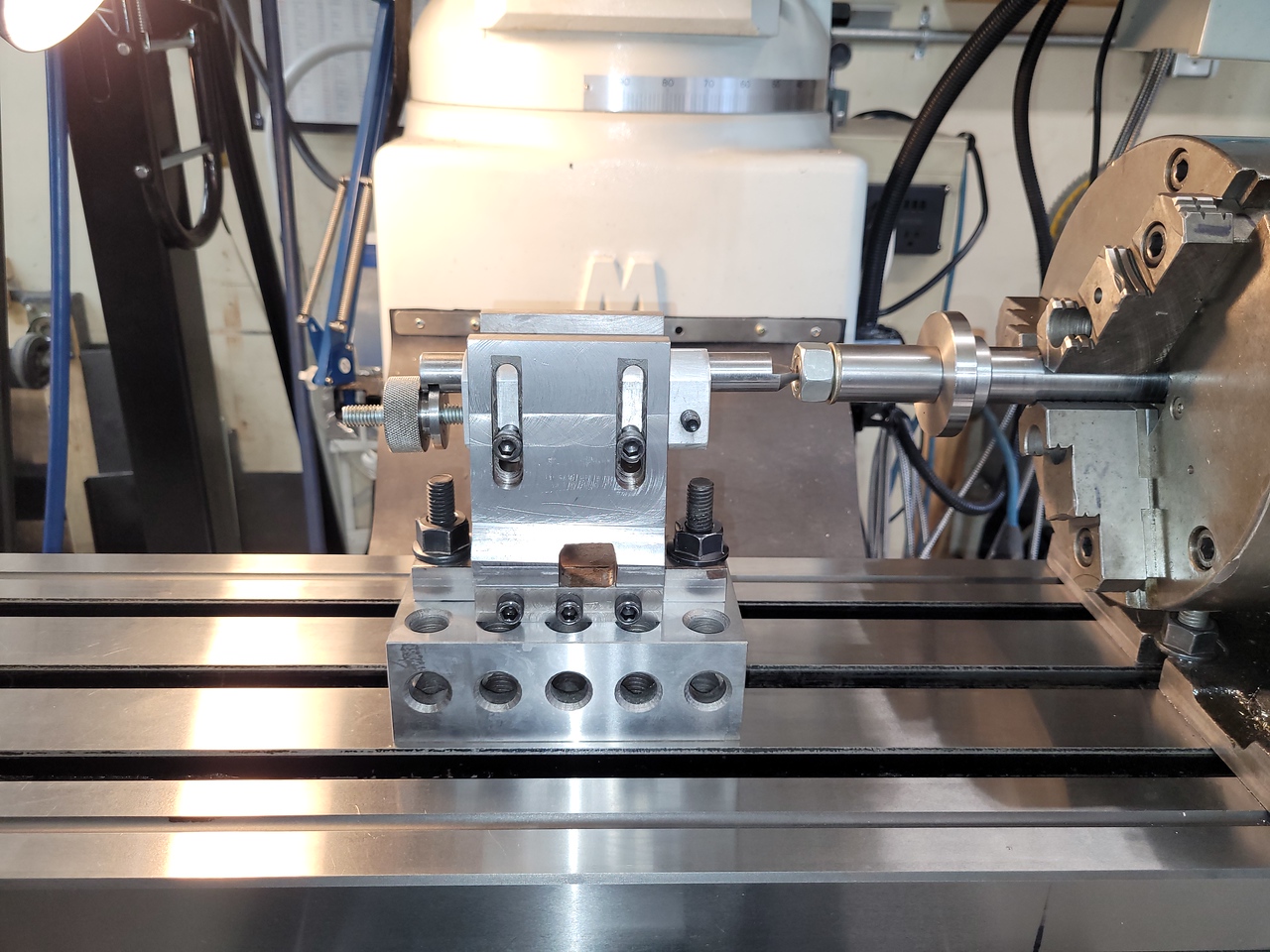

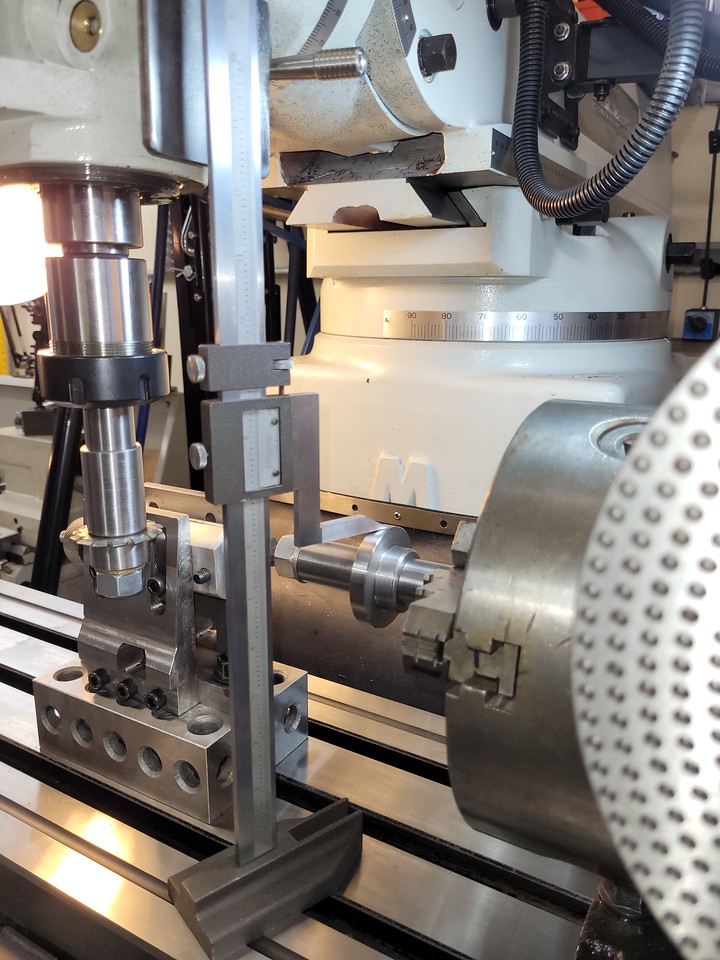

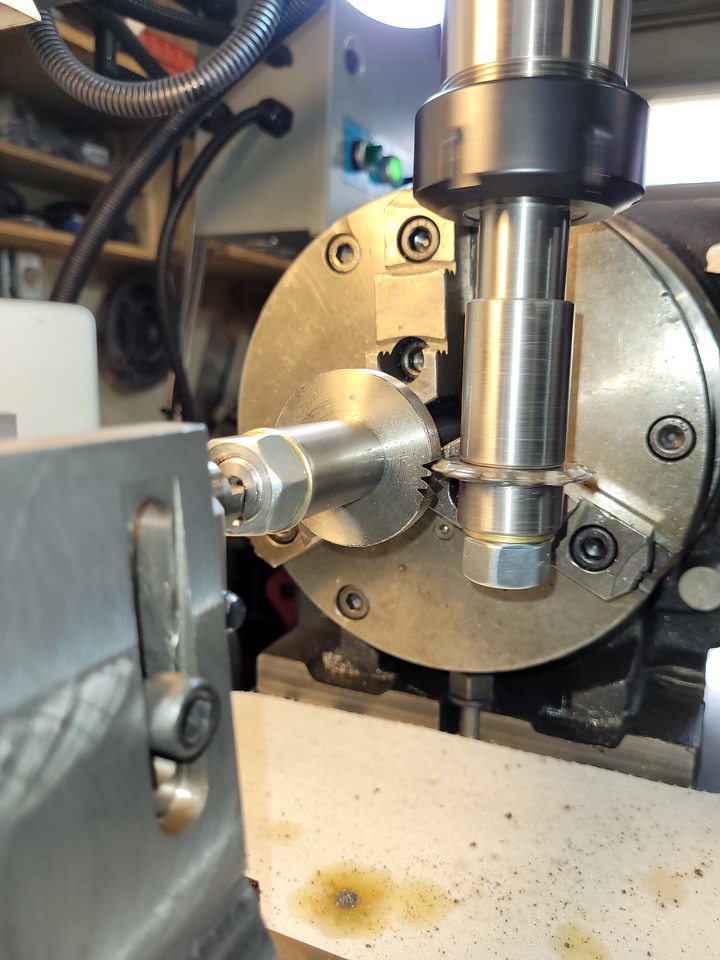

I installed the 19mm arbor in the Vertex super spacer and indicated the shaft to set it parallel to the mill X axis and also checked that it was parallel to the table horizontally.

Then I set up the footstock to support the end of the arbor. I'm not sure this was 100% necessary but it seemed like a good idea.

To get the cutter on the center line of the gear blank I measured to the top of the blank with my height gage then subtracted half the diameter of the blank and was reassured when it measured 6.100" since I know that is the center height of the Vertex spacer. To get the cutter to that height I measure to the top edge of the cutter and added half it's thickness.

I had conflicting information from 2 sources about the depth of cut to make, Maryland Metrics says for a 1.25 module gear it should be .106" and Evolvement Design says it should be 2.25 X the module pitch which makes .110". So I decided to measure it. I slid one of my 40 tooth gears onto the arbor and moved the Y axis until the tip of a cutter tooth just contacted the top of one of the gear teeth, then set 0 on the DRO and advanced to Y until the tooth bottomed in the gear. I measured .123" on both 40 tooth gears and .120" on the 30 and 32 tooth ones. I decided to use .121" as my cut depth to try and match my existing gears as close as possible.

I wasn't sure how much of the depth I could cut in one pass so I tried .030" then .060" then the entire .121" and with a very slow feed rate it seemed fine to do the full depth in one pass. Spindles speed was set at 215 rpm and feed rate was set just about as slow as it can go on my table power feed. For the 42 tooth gear it was make a pass, turn the indexer 2-9/63 turns and make another pass. The cutter performed well and it seemed to slice through the 4140 gear blanks with little effort.

Here's a short video showing a few cuts.

Metal working projects - John Conroy

This video hosted by SmugMug; your photos and videos look better here.johnconroy.smugmug.com

The finished gear.

More of the same for the 36 tooth gear except I didn't need the indexing plates, just cut a tooth every 10 degrees.

Tomorrow I'll install them on the lathe and cuts some 1.75mm threads!

Just to return for a moment to gears on Susquatch's lathe, what are stock listed gears for imperial threads as per plaques on lathe/ ops manual? Mine is the 30 on "a" shaft and 60 on "b" shaft. This allows cutting most all common pitchs in imperial. Other gears are mostly for cutting metric pitchs. Haven't filled the spaces in on the metric plaques as of yet, appears "best" combo will cut 2 common metric pitchs with out a change.

I have not really looked to see if any of my gears are unique to metric threading other than the 127. I'm still being over-supervised by SWMBO, but I'm pretty sure I can get away with looking at my gears for a while later today. I'll do that and report back later.

Wow, thanks for sneaking out to the shop. Still got snow there? Leaves tracks.

Anyway, I am rubbing my head and wondering just how many different gear boxes/setups are on these lathes that are "clones". No, I don't really need to know,LOL. I don't change the gear train on mine for the common imperial threads. But it does appear if I run no reduction from "a" shaft to "b" shaft, maybe able to get 4 to 7 pitch imperial, not that I will need it any time soon.

There is one gear set I need to take a look at, a single hub, double gear, have no idea what it is for or where it may go. A picture would help I know, however--. The joys of no reading manual.

I determined the gear pitch to be module 1.25.