That's one of the ideas that came to me too.something something silk purse something something sow's ear. I'd be thinking about how to add a high-speed spindle to the mill.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

JCDammeyer's 42 projects

- Thread starter jcdammeyer

- Start date

Dan Dubeau

Ultra Member

I had them made in China. Just googled making puzzles from photos or something to that effect. It wasn't even expensive. This was 500 pieces I think. I wasn't impressed with the quality of the colour. The puzzle was much pinker than the original photo.

Thanks for the idea. I'm going to get some of my Wifes yarn colour gradients made into a puzzle for a Christmas gift for her.

The upside of the lions gate bridge puzzle was that there is a numeric grid printed on the back. The actual die to stamp out the puzzle pieces (which are thin plywood) duplicates the pieces way too much. As in there are way to many pieces that fit in other places. Likely because it's a cheap puzzle. But the numeric grid on the back helps with that.Thanks for the idea. I'm going to get some of my Wifes yarn colour gradients made into a puzzle for a Christmas gift for her.

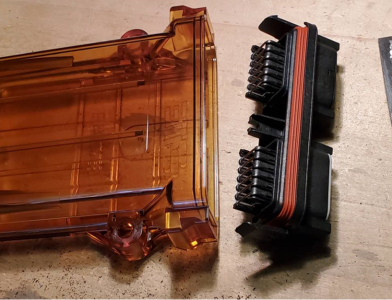

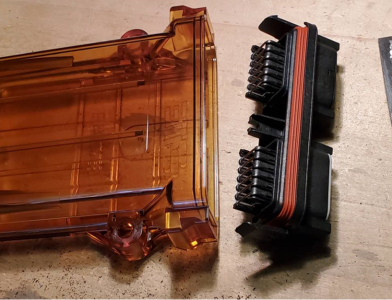

In the past I’ve had to file the two tabs because at some point the company making them changed the molds ever so slightly and now it takes a huge amount of force to press the connector into the box. It deforms (Compresses) the plastic tabs. The problem is if you have to take it apart you pretty well break the box as it’s really hard to deform them for removal.

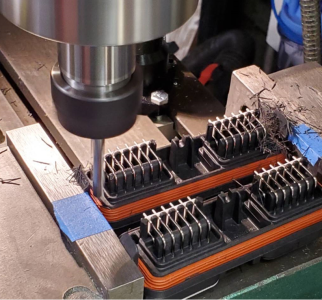

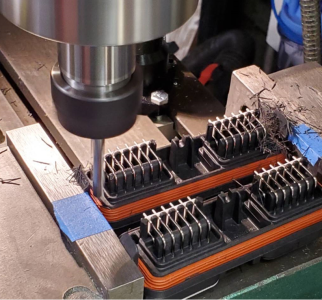

So I thought. Crap. I have a mill. I have to do 50 of the puppies. I don’t feel like filing them all. So with a bunch of manual jogging and noting XYZ positions and doing a few manually I now have a G-Code program.

So much easier.

So I thought. Crap. I have a mill. I have to do 50 of the puppies. I don’t feel like filing them all. So with a bunch of manual jogging and noting XYZ positions and doing a few manually I now have a G-Code program.

So much easier.

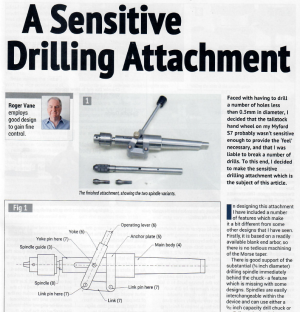

Going through some older Model Engineer magazines I ran across this. Looks interesting and would be much easier to build with CNC on the mill. I've attached a link to the two articles as a 300 DPI PDF which is too large to include in this forum.

Since @David has a CNC mill and he's so quick I'm thinking I can pick up the one he'll make for me this coming Friday?

app.box.com

app.box.com

Since @David has a CNC mill and he's so quick I'm thinking I can pick up the one he'll make for me this coming Friday?

Box

Finally got around to making some table covers to keep the crap out of the T-Slots. The tool height tester caused a lot of issues. First time, measured incorrectly. Second time too thick in one spot for the nut that captured the cable. Third time a nice fit but too far back so the T-Slot guides didn't fit.

Finally gave up and made a round spot for it. I can make a new insert now that prints faster and the angle of the rectangle isn't important.

Finally gave up and made a round spot for it. I can make a new insert now that prints faster and the angle of the rectangle isn't important.

Attachments

philipFROM-PNW

Member

So sorry for your lossThanks. I have a Pharmacist wife. He had a brand new kit in his bag. He'd been Narcanned twice that evening. Even so fatal quantity in his blood. As the coroner told me today is that even in the hospital with all the gear they still lose patients to this.

My utmost Condolences

philip, from the Great Pacific NorthWET, Oregon, USA

. . . . working for Jesus Christ, since 1967

Last edited by a moderator:

For anyone who wants to make something similar here's the step files. I inserted a plane and then extruded/cut in either direction to create the half pieces. They just fit into the Bambu printer. The rails and dowels were printed on the SOVOL. The plan was also to make a rectangular insert that fit in the end of the mill table but instead I have a hole in the end of the rail and I can just insert a bolt that presses against the end of the table.Finally got around to making some table covers to keep the crap out of the T-Slots. The tool height tester caused a lot of issues. First time, measured incorrectly. Second time too thick in one spot for the nut that captured the cable. Third time a nice fit but too far back so the T-Slot guides didn't fit.

Finally gave up and made a round spot for it. I can make a new insert now that prints faster and the angle of the rectangle isn't important.

View attachment 68361

Once I create a nice insert for the tool height sensor I'll glue the pieces together and prime/paint. Maybe an epoxy paint to deal with various coolants or lubricants.

Yes. Over kill....

Attachments

The black insert now fits perfectly. There are three guides underneath that fit into the T-Slots. And it's now painted the same colour as the mill. Almost looks like it came with it. Although too clean but then the paint is still sticky so I have to wait a bit before I can make it dirty.

Let's see... Remove this project from the list of 42 projects. Count items left on the list.... Damn! Still 42 on the list.

Let's see... Remove this project from the list of 42 projects. Count items left on the list.... Damn! Still 42 on the list.

I only take orders from my wife.Looks good. Are you taking orders? 😀

A friend suggested I put a sticky layer of clear plastic on the wood and then rout through that. I have tried clear packing tape. Left granules of melted plastic that needed cleaning but seemed to work. I've sprayed that with red paint. When it dries I'll put down a layer of Varathane to cover the red. Then pull the tape and sand/stain the rest of the wood. See how that works.We don't want people stealing our small crop of pears so I thought I'd make a few Private Property signs on the CNC router.

Cedar. Top one cut first and then smoothed on the jointer. Took away too much of the letters. Second one joint the surface first and then cut the lettering.

View attachment 68576

Last edited:

140mower

Don

.... A wise man once said... 🙄 😛I only take orders from my wife.

Yes?.... A wise man once said... 🙄 😛

I use blue painters tape.A friend suggested I put a sticky layer of clear plastic on the wood and then rout through that. I have tried clear packing tape. Left granules of melted plastic that needed cleaning but seemed to work. I've sprayed that with red paint. When it dries I'll put down a layer of Varathane to cover the red. Then pull the tape and sand/stain the rest of the wood. See how that works.

With what type of cutter?I use blue painters tape.