Well. Just finished assembling 45 of these.

Now to finish 20 of the little boards for this version. The main set of 20 are already done.

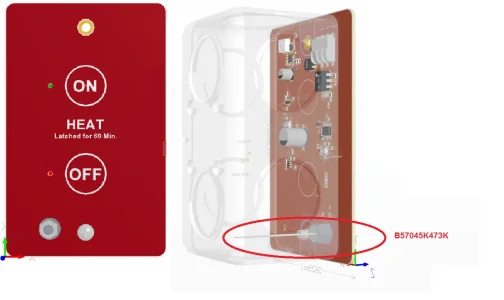

Waiting for the small DIP relays that should arrive tomorrow which means I can finally get back to the air compressor cooler installation. Tomorrow the Thermisters will also arrive so I can measure inlet/outlet temperatures. The above module with two small DIP relays is set up for two Thermisters so I have something ready to go to read those temperatures and the pressure sensor.

Have to read up again on using the bender and the Right and Left markings as to where to do the bend.

Now to finish 20 of the little boards for this version. The main set of 20 are already done.

Waiting for the small DIP relays that should arrive tomorrow which means I can finally get back to the air compressor cooler installation. Tomorrow the Thermisters will also arrive so I can measure inlet/outlet temperatures. The above module with two small DIP relays is set up for two Thermisters so I have something ready to go to read those temperatures and the pressure sensor.

Have to read up again on using the bender and the Right and Left markings as to where to do the bend.