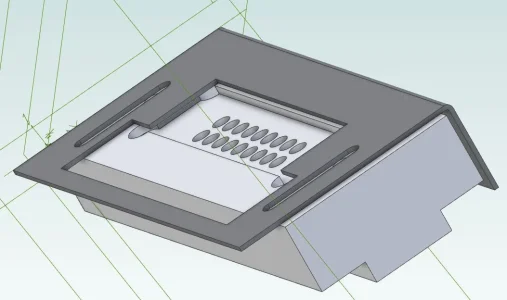

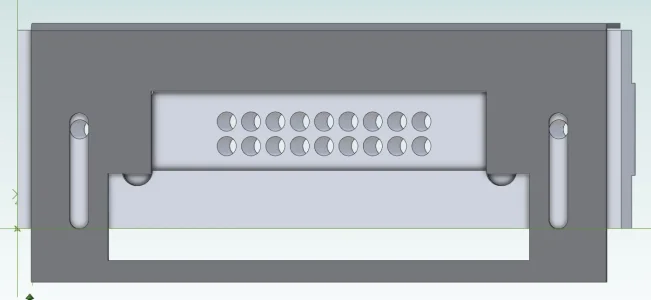

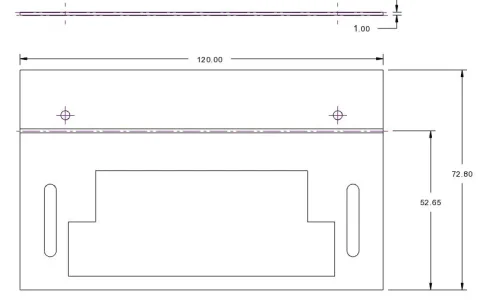

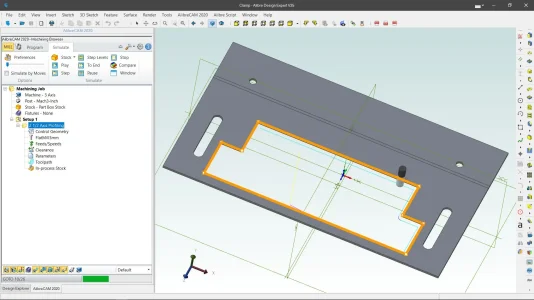

I found I'd already done this model a few years ago. I added the clearance holes based on the dimensions from the front plate drawing.

The 0.125" up cut router bit didn't do the best job on the holes this time. Maybe it's dull. I used this 0.125" in a hand drill to clean them out.

If I make that metal jig for the mill then I can ensure the vise jaws are parallel to the X axis. Then indicate off the bottom left end and side for X,Y==0,0. Then use a 3.5mm mill (0.138") which will make the light pipes a bit less of a tight fit.

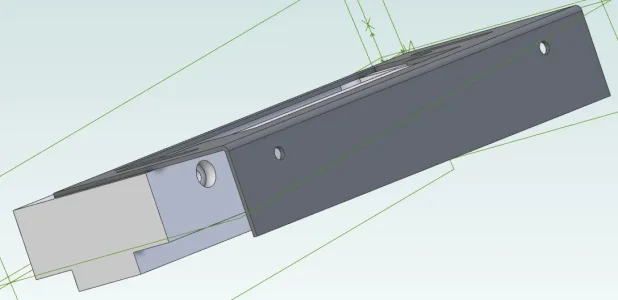

So far all simple enough. But the large toggle clamp used on the CNC router isn't really suitable there. Maybe some sort of tabs that pivot on those two holes to hold the plate in place?

Looking for suggestions.

The 0.125" up cut router bit didn't do the best job on the holes this time. Maybe it's dull. I used this 0.125" in a hand drill to clean them out.

If I make that metal jig for the mill then I can ensure the vise jaws are parallel to the X axis. Then indicate off the bottom left end and side for X,Y==0,0. Then use a 3.5mm mill (0.138") which will make the light pipes a bit less of a tight fit.

So far all simple enough. But the large toggle clamp used on the CNC router isn't really suitable there. Maybe some sort of tabs that pivot on those two holes to hold the plate in place?

Looking for suggestions.