-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

JCDammeyer's 42 projects

- Thread starter jcdammeyer

- Start date

Busy printing...Try this John.

I sized it up 101% to fit the Matter3D reels.

I misunderstood and thought the file you posted was already 101% but turns out not. Way too small. Then I measured the Matter3D spool and compared it to the Elegoo spool which turns out to be larger and took a swing at 105%. Way too large. So then I went 102% in X and Y.Busy printing...

Nice fit. Just waiting now for the second half and then I'll try an Elegoo

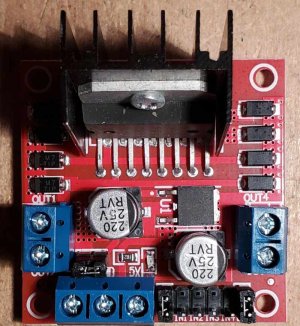

This was a bit more difficult than I expected. I had to remove one of the motor terminal blocks to get at the capacitor. Then pulled it up too quickly and damaged a bit of the PC land on the other terminal. Added some 0.1uF caps and I by chance had two 220uF 35V radial caps the same size on hand. Installed all that and I've left the diodes for now.I saw these items from Amazon on that you had.

They look very much like some potentiometers I bought to control the speed of some mini DC motors that I had put into an actuator setup.

View attachment 60890

Ran 24V into it and the motor ran with 22V. Increased the input voltage to 25.7V to get 24V across the motor. Draws a total of 300mA at 25.7V which is 7.7W. I'm also running the encoder from the 5V and it's a nice stable waveform.

Next step is a bit of Arduino code I guess to control motor speed. But glad I replaced the caps since 25V caps with 25.7V is a tad too close to the edge for me. Probably work but I don't like blowing up caps.

Forgot to post the photos. Here's an original with the 25V Electrolytics and no high frequency bipass caps.This was a bit more difficult than I expected. I had to remove one of the motor terminal blocks to get at the capacitor. Then pulled it up too quickly and damaged a bit of the PC land on the other terminal. Added some 0.1uF caps and I by chance had two 220uF 35V radial caps the same size on hand. Installed all that and I've left the diodes for now.

Ran 24V into it and the motor ran with 22V. Increased the input voltage to 25.7V to get 24V across the motor. Draws a total of 300mA at 25.7V which is 7.7W. I'm also running the encoder from the 5V and it's a nice stable waveform.

View attachment 60951

Next step is a bit of Arduino code I guess to control motor speed. But glad I replaced the caps since 25V caps with 25.7V is a tad too close to the edge for me. Probably work but I don't like blowing up caps.

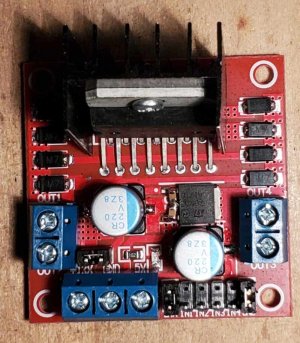

Here's a modified one with the 0.1uF (100nF) on both the VS and VSS pins of the driver.

And on the top side, new electrolytics good to 35V and look closely on the 78M05 you will see two 0803 size 0.1uF caps tacked onto the pins.

I have yet to swap out the 1N4007 rectifier diodes for for Schottkey high speed low dropout voltage diodes.

It will not be easy to add any sort of over current support on this board. I'd have to design a new one and move the parts over.

Sorry about that, I should have been more clear.I misunderstood and thought the file you posted was already 101% but turns out not. Way too small. Then I measured the Matter3D spool and compared it to the Elegoo spool which turns out to be larger and took a swing at 105%. Way too large. So then I went 102% in X and Y.

Nice fit. Just waiting now for the second half and then I'll try an Elegoo

The Anycubic rolls are slightly small diameter than the Matter3D rolls.

Looks like the Elegoo will work but printer is busy at the moment making a watering can with a small spout so I can more easily water the seed pods in Herbus. Another hour to go before this puppy is done.Sorry about that, I should have been more clear.

The Anycubic rolls are slightly small diameter than the Matter3D rolls.

Hmmm. With the two pieces on a brand new Elegoo cardboard holder full of white filament the reel is now so large it actually rubs on the top of the AMS. Not really tightly but enough to mark the surface.Sorry about that, I should have been more clear.

The Anycubic rolls are slightly small diameter than the Matter3D rolls.

So I'm back to rewinding what I have onto plastic reels.

Couldn't resist. My morning chuckle.

Couldn't resist. My morning chuckle.

View attachment 61069

Best not let your dance partner see that post!

Gee, in looking through my project boxes for an encoder I found this project. Still works. Software is from 1997 for a PIC16C57 which requires a programmer and a UV lamp eraser.

Ah the good old days of wire-wrap.

Ah the good old days of wire-wrap.

And with that encoder connected to an Arduino UNO R4 and a bit of research on the web I have output logged to the serial port:

First number is absolute encoder count and second one is number of pulses per time interval which in this case is 1 second and me trying to turn the encoder at a repeatable rate. Ha ha. Going to have to connect this to a motor to see real pulses per second.

Terminal log file

Date: 2025-03-07 - 4:02:22 PM

-----------------------------------------------

52718 0

52726 8

50700 -2027

52756 2057

55748 2993

60253 4507

63066 2810

1306 3776

5794 4489

11130 5335

11288 158

11288 0

11288 0

-----------------------------------------------

Date: 2025-03-07 - 4:02:35 PM

End log file

First number is absolute encoder count and second one is number of pulses per time interval which in this case is 1 second and me trying to turn the encoder at a repeatable rate. Ha ha. Going to have to connect this to a motor to see real pulses per second.

Terminal log file

Date: 2025-03-07 - 4:02:22 PM

-----------------------------------------------

52718 0

52726 8

50700 -2027

52756 2057

55748 2993

60253 4507

63066 2810

1306 3776

5794 4489

11130 5335

11288 158

11288 0

11288 0

-----------------------------------------------

Date: 2025-03-07 - 4:02:35 PM

End log file

Moving along here today I spent time on the lathe. Yeah. Metal working. Spent a few minutes looking for the 3-jaw chuck key. Had totally forgotten that it has a place in the tool caddy with all the 5C collets.

Anyway. Starting with 1/2" unknown steel with orange paint on the end I turned down to 1/4" for about 10mm and center drilled the end. The 1/4" is to fit into a ball bearing in the junk box.

Then the 12mm diameter. Finally the 1.75mm pitch threading until a nut just smoothly went on. Better than when the nut goes onto a standard bolt.

The other end was turned down until 8mm and a smooth sliding fit into another bearing and the coupler for the motor.

Meanwhile 3D printing various frames. Haven't decided on a final design yet. The arm that guides the filament pivots in the grey piece which is moved back and forth 1.75mm per revolution of the take-up spool. The software will let us specify how many turns for the plastic hub. It varies between 42 and 46.

Anyway. Starting with 1/2" unknown steel with orange paint on the end I turned down to 1/4" for about 10mm and center drilled the end. The 1/4" is to fit into a ball bearing in the junk box.

Then the 12mm diameter. Finally the 1.75mm pitch threading until a nut just smoothly went on. Better than when the nut goes onto a standard bolt.

The other end was turned down until 8mm and a smooth sliding fit into another bearing and the coupler for the motor.

Meanwhile 3D printing various frames. Haven't decided on a final design yet. The arm that guides the filament pivots in the grey piece which is moved back and forth 1.75mm per revolution of the take-up spool. The software will let us specify how many turns for the plastic hub. It varies between 42 and 46.

Moving along here today I spent time on the lathe. Yeah. Metal working.

Go figure, I've been wondering if you could do that!

Spent a few minutes looking for the 3-jaw chuck key. Had totally forgotten that it has a place in the tool caddy with all the 5C collets.

See! That's what is wrong with filers and neat freaks. I always know exactly where my key is. It is always in a pile on the closest surface to where I use it.

Then the 12mm diameter. Finally the 1.75mm pitch threading until a nut just smoothly went on. Better than when the nut goes onto a standard bolt.

I love this about single point threading too. The method's only downfall is that a different nut might not work.

Actually I ran the tap through the nut just like I cleaned up the 3D printed threads with the tap. A new nut from Cdn Tire or Rona etc may be a bit tight. But I wanted a close tolerance fit as the 3D printed piece (or later maybe Delrin or Nylon) is the lead screw.Go figure, I've been wondering if you could do that!

See! That's what is wrong with filers and neat freaks. I always know exactly where my key is. It is always in a pile on the closest surface to where I use it.

I love this about single point threading too. The method's only downfall is that a different nut might not work.

I do have a die so I could have chased the threads with the die. Might still do that but yes single point threading 1.75mm pitch with the South Bend Heavy 10L that has a 10TPI lead screw.

A bit of progress. I'll post a link to a youtube video of the lead screw tracking the 400 line encoder.

There's an issue with the Arduino code I'm trying out. Once the motor is in motion it no longer can get the information from the encoder. But then the software on the Arduino was just to test out the motor driver.

Last edited:

OK. While I wait for bearings to arrive to fit inside the TPU printed tension rollers I thought I'd take another stab at slowing down @David

He's going way too fast on his CNC conversion but I think I've figured out a way to muck with his head.

Recall he's had a CNC router for a number of years pretending to use it and cut things........

Well. LinuxCNC when we look at the machine co-ordinates after homing looks like this:

And it does make sense right. For a CNC router we've gone up first out of the way of everything and then moved X and Y over to the home switches. Now a move of the cutter to the right increases X and a move away from us increase Y both in a positive direction.

Makes perfect sense for a router. Even so for a CNC mill where the head moves upwards to the home switch out of the way of everything.

The problem is we don't really know the distance from the TTS tooling reference surface (bottom of the quill) to the table.

Why do we need to know this?

Simple. Everything is placed onto the table in one form or another. And when you have a tool setter it's nice to be able to measure the length of a tool and put it into the tool table. (And know what is happening).

So here's an example:

With the Head all the way up or the table all the way down (Knee mill) we need to be able to measure this distance because it changes as soon as we tweak the home switch position.

And a side effect of this is as we move closer to the table the distance changes from 0.000 to a negative number so for the rest of this discussion we'll mostly talk about absolute values.

This is where I get to muck with head of @David. Much easier to think of he Z value being 12.718 and as we move closer to the table that value gets smaller.... For that matter how do we measure the actual height when our tool setter trips under pressure from the tool?

How do we know that since we don't know the distance to the table? Especially if the quill registration won't even reach the table

This requires one or two 1-2-3 blocks..

After a Home Operation our Machine Co-ordinate Z=0.0000. If we move the head down until we can just barely shove a 1-2-3 block under (say the 3" distance) we can record that number. In my example above that would be Z=-9.7180". In other words we've just moved the Z axis 9.7180" in the direction of the table (or the knee upwards) but it's a negative direction. Add the -3.00 size of the 1-2-3 block to that and now we know the quill TTS reference surface is 12.718" from the table after a home position.

Why is that important. Say we now move the head down (or the knee up) and have the reference surface of the quill touch the tool setter. When it trips we stop. Again we'll see some sort of strange negative number that doesn't make any sense.

Oh but wait! The Z axis reads -9.055" when we trip the tool setter. If we take the absolute value of that and subtract that from the overall height of 12.718 we discover the tool setter height when tripped is 3.663".

That's important and we need that value when we use the tool setter to determine how long a TTS held tool is. More on that after @David recovers from the confusing information.

He's going way too fast on his CNC conversion but I think I've figured out a way to muck with his head.

Recall he's had a CNC router for a number of years pretending to use it and cut things........

Well. LinuxCNC when we look at the machine co-ordinates after homing looks like this:

And it does make sense right. For a CNC router we've gone up first out of the way of everything and then moved X and Y over to the home switches. Now a move of the cutter to the right increases X and a move away from us increase Y both in a positive direction.

Makes perfect sense for a router. Even so for a CNC mill where the head moves upwards to the home switch out of the way of everything.

The problem is we don't really know the distance from the TTS tooling reference surface (bottom of the quill) to the table.

Why do we need to know this?

Simple. Everything is placed onto the table in one form or another. And when you have a tool setter it's nice to be able to measure the length of a tool and put it into the tool table. (And know what is happening).

So here's an example:

With the Head all the way up or the table all the way down (Knee mill) we need to be able to measure this distance because it changes as soon as we tweak the home switch position.

And a side effect of this is as we move closer to the table the distance changes from 0.000 to a negative number so for the rest of this discussion we'll mostly talk about absolute values.

This is where I get to muck with head of @David. Much easier to think of he Z value being 12.718 and as we move closer to the table that value gets smaller.... For that matter how do we measure the actual height when our tool setter trips under pressure from the tool?

How do we know that since we don't know the distance to the table? Especially if the quill registration won't even reach the table

This requires one or two 1-2-3 blocks..

After a Home Operation our Machine Co-ordinate Z=0.0000. If we move the head down until we can just barely shove a 1-2-3 block under (say the 3" distance) we can record that number. In my example above that would be Z=-9.7180". In other words we've just moved the Z axis 9.7180" in the direction of the table (or the knee upwards) but it's a negative direction. Add the -3.00 size of the 1-2-3 block to that and now we know the quill TTS reference surface is 12.718" from the table after a home position.

Why is that important. Say we now move the head down (or the knee up) and have the reference surface of the quill touch the tool setter. When it trips we stop. Again we'll see some sort of strange negative number that doesn't make any sense.

Oh but wait! The Z axis reads -9.055" when we trip the tool setter. If we take the absolute value of that and subtract that from the overall height of 12.718 we discover the tool setter height when tripped is 3.663".

That's important and we need that value when we use the tool setter to determine how long a TTS held tool is. More on that after @David recovers from the confusing information.

Last edited:

@David I'm afraid 42 furlongs per fortnight is a rate measurement not a distance measurement.Well the answer is 42 of course!