You can also use bondo using a release agent to get it in position.

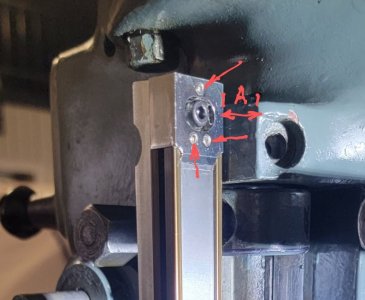

I did that for the knee scale - except I used a 2-part epoxy wood filler instead of bondo.

You can also use bondo using a release agent to get it in position.

Looks good.

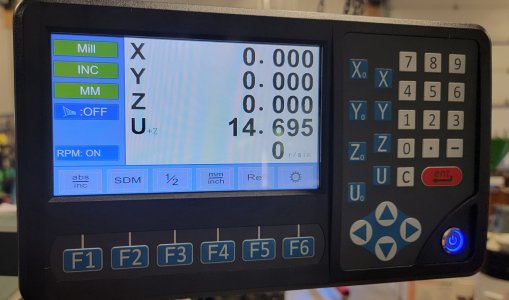

Not quite sure I follow the DRO display. Just to confirm, you have it set up so Z = knee and U+Z = (quill + knee) combined? (as opposed to quill as an independent value)?

So you're saying it is possible to set it up as Z & U completely independent to one another? Or it forces some permutation of axis 'addition' once the quill axis input is introduced into box?

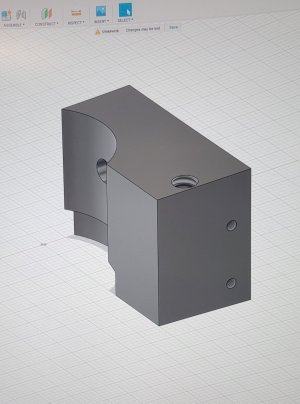

Care to detail a little further how you attached the sensor to the quill indicator? Does the aluminium block wrap around and the screw apply presure, or did you drill and tap the follower?

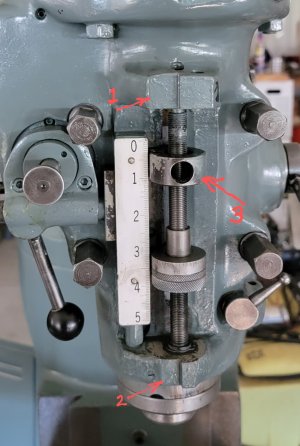

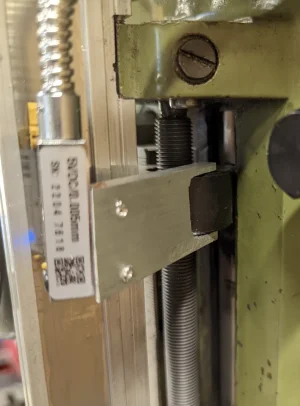

I've gotten as far as this, and am contemplating options:

I have a set screw in the bottom of the fork. I'm certain this will rattle loose. The bevel on the end of the bar is sufficiently out from what it needs to be for the head that I'm surprised how well it reads - I'm accurate to my gauge blocks on quill travel. These magnetic scales are *very* forgiving. Cosine error is also very forgiving over this 5-6" travel length.

I believe you are bang on. The error is effectively negligible in this alignment. Certainly it's less than induced between sides of a cutter by less-than-perfect tram, for example.My math says that if the scale is out of alignment by 1/16” over 6”, the hypotenuse of the triangle formed between the scale and the reference surface would be 6.00033”. So the potential error between readout and reality would be 0.00033”.

Yes, I lose a few millimeters at both ends. I've never reached the bottom, and I'm happy losing the 2mm at the top ;-)Don't you loose a bit of travel at both ends? Either way it wouldn't bother me either.

I have a question for those of us who are much fussier than I am. I see references to cosine errors regarding alignment of scales.

And this is the piece I don't know how to measure. I can pull out my longest gauge block and check over that length, but that's it. So I can adjust for the error over 4", but on an X axis with 36" of travel that doesn't seem particularly useful.The jury is still out on the issue of linearity and proportionality.

And this is the piece I don't know how to measure. I can pull out my longest gauge block and check over that length, but that's it. So I can adjust for the error over 4", but on an X axis with 36" of travel that doesn't seem particularly useful.

It's good that you saw the light!You have to promise not to laugh.......

I use a long shaft indicator for distances less than 3 inches, a vernier for distances up to 8 inches and...are you ready...... a laser for longer distances. It's easily accurate enough for my long distance needs.

I wouldn't mind having a few long standards for comparisons though.