I commend you guys with the intricate quill DRO set ups. I planned on doing it as well, but I decided to cobble up something to test if I would really make use of it. Yes, its quite useful especially for drilling to exact depths. But I haven't had the opportunity (=lazy) to make a more stable set up. In the photos, I have the bar clamped to the quill threaded bolt, and the reading head held on by a magnet. Pretty red-neck, but it works.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Installing a DRO on a Hartford Bridgeport Clone.

- Thread starter Susquatch

- Start date

Pretty red-neck, but it works.

Hey, if it works, it works!

But ya, soon enough you will be making something better than either of us have done!

To your overall point though. I have absolutely no idea why I took 50 years to figure out how useful a DRO is. Never mind the fancy patterns. Ya, they are nice. But the sheer amazing ability to do two simple edge findings (for x & y and Z if you have it), and then go where you wanna go is simply a complete new paradigm shift!

I LOVE MY DRO!

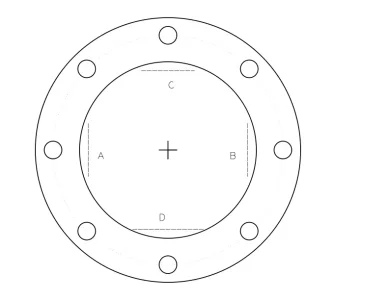

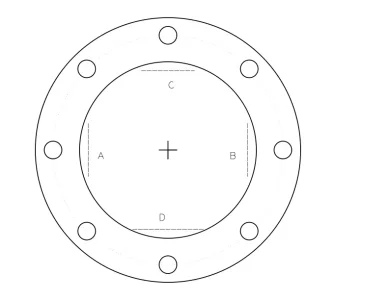

Thing I love about a DRO is finding centre. I machine a lot of pipe flanges, and always have to find centre in the flange I.D.

DRO:

Bolt flange to mill table

put edge finder roughly in the centre of the i.d.

Lock axis c-d

move edge finder to touch around A

zero DRO a-b axis

move edge finder to touch B

note DRO reading, move left until DRO reading is half

zero DRO

Lock axis a-b

move edge finder to touch around C

zero DRO c-d axis

move edge finder to touch D

note DRO reading, move back until DRO reading is half

zero DRO

done - centre of a hole, true to I,D, O.D, and bolt circle

Takes less time to do than describe

DRO:

Bolt flange to mill table

put edge finder roughly in the centre of the i.d.

Lock axis c-d

move edge finder to touch around A

zero DRO a-b axis

move edge finder to touch B

note DRO reading, move left until DRO reading is half

zero DRO

Lock axis a-b

move edge finder to touch around C

zero DRO c-d axis

move edge finder to touch D

note DRO reading, move back until DRO reading is half

zero DRO

done - centre of a hole, true to I,D, O.D, and bolt circle

Takes less time to do than describe

Takes less time to do than describe

Mine has a divide by two function built right in. Zero on any edge, go to opposite edge, divide by 2, set axis. All done that axis. Repeat for other axis.

Nice thing about doing both sides that way is that tool Width (or edge finder width) doesn't matter. Settles out of the broth.

Ordered one today too. Took advantage of the KBC coupon - 100 off of 575. Got some way oil, an 8" Mitutoyo caliper, Noga too. Free shipping too.

The bride decided to go shopping today. I watched her turn onto the highway and headed straight for my shop....

When the cat is away, the rat will play! (Insert evil grin here....)

I stood at the door surveying my vast kingdom stretching for thousands of miles before me contemplating what to do.... Ignoring 42 other projects, my eyes settled on "Install Cable Reliefs on Mill DRO".

Grabbed my 1/8 carbide drill to handle the undrillobillium the saddle is cast from and had at it!

Such pure joy doing such a simple project.....

But such a "relief" to know its unlikely that I'll ever pull a cable out of a read head now.

I put 2 Reliefs on the X-Axis cable so the cable would reliably clear the oil pump handle.

I still have to do the quill and the knee but they are no biggie and it's time to go back the house before the cat gets home.

When the cat is away, the rat will play! (Insert evil grin here....)

I stood at the door surveying my vast kingdom stretching for thousands of miles before me contemplating what to do.... Ignoring 42 other projects, my eyes settled on "Install Cable Reliefs on Mill DRO".

Grabbed my 1/8 carbide drill to handle the undrillobillium the saddle is cast from and had at it!

Such pure joy doing such a simple project.....

But such a "relief" to know its unlikely that I'll ever pull a cable out of a read head now.

I put 2 Reliefs on the X-Axis cable so the cable would reliably clear the oil pump handle.

I still have to do the quill and the knee but they are no biggie and it's time to go back the house before the cat gets home.

Last edited:

Get any grease on those lily-white paws? Askin' for a friend...I put 2 Reliefs on the X-Axis cable so the cable would reliably clear the oil pump handle.

Get any grease on those lily-white paws? Askin' for a friend...

Unfortunately yes, but all very carefully and meticulously removed before SWMBO got home.

So far my escapade has gone unnoticed. (Insert crossed fingers here).

grease monkey

just another day!

wow, nice job with the install and the updates! you did not mention where you sourced the Ditron, or I missed in my sped redding, I also seen the absolute grief you all have with hard drilling and the cost of carbides... anyone ever use masonry bits sharpened to a cutting profile? way cheaper and cut like the dickens!!! I bought a handful of each size to side grind them down to the hole diameter I needed and profiled a drill edge to them, sure is fun drilling hard material for cheap!

you did not mention where you sourced the Ditron, or I missed in my sped redding,

I bought both of mine from the Ditron Store on AliExpress. They are quite a challenge to negotiate with though.

If I were buying again today, I would buy from the Ditron store on Amazon instead. I think it's actually the same people in both place cuz they seem to know each other. But the Amazon store said they would match the Ali store prices. I prefer the safety of free returns and free shipping at Amazon.

I also seen the absolute grief you all have with hard drilling and the cost of carbides... anyone ever use masonry bits sharpened to a cutting profile?

No I've never tried that. At the time I had no way to sharpen carbide. I will try that someday soon. Perhaps sooner than later as I want to install some limit switches on the front of my mill table for an x-axis power feed.

grease monkey

just another day!

was in Lakeshore on sat, drove right by You, maybe next time!