thats a strong endorsement, glad its working well for you.

Cuttermasters, seems some sort of incarnation of Cuttermaster, no "s". The Cuttermaster was available in two styles, with a column and without. imo the column drastically improves its functionality. It was made in the US was a good quality machine. Looking at the CuttermasterS, I do not like the column, doesn't seem very substantial. I also am shocked at the price, 9600? Wow. I assume its made in China as Accusize also sells it, but their web site claims made in Canada and US.

There is some weirdness around the name/brand. Knowing the original machine was definitely "Cuttermaster" (manual page below), I kind of became the proverbial dog with a bone trying to figure it out. Cuttermaster belonged to Conquest Industries Inc, Santa Fe. The cuttermaster.com url sits unused and and Conquest Industries no longer lists them as a product.

Accusize's web site notes "Cuttermasters with an S is a multinational company. It has

offices and factories across Canada and the U.S. Its products include Drill Sharpeners, End Mill Sharpeners, Annular Cutter Sharpeners, Neck Relief, Weldon Flat Grinding, Corner Radius, Carbide Cut Off, etc.

All the Cuttermasters products are made in Canada or made in the U.S.". It looks like there is lone Canadian office and "factory" is a bungalow in Ottawa, 2353 Ridgecrest Pl. The US web site claims made there (US), seems surprising and I'm doubtful. Furthermore, Cuttermasters's US website gives the address 808 Proctor Ave, Ogdensburg, NY, which appears to be a freestanding building with NAS Logistics, a drop ship/forward as the occupant.

Toycen Industries of Ottawa claims to have designed the Cuttermaster Professional. Jeff Toycen is listed as the President of Cuttermasters, and his web site says they are active in Business Analytics, Construction Planning, Energy Infrastructure, Global Markets, Startup Funding and Wealth Management. The empire's HQ is 2353 Ridgecrest Pl, Ottawa. A 411 search says there is a J Toycen living at 2353 Ridgecrest Pl.

It's possible they could still have NA manufacturing, but they try very hard to hide it. They claim a amazing list of customers (Gucci, Rolls Royce, Amazon, Google, NASA and Pauls Tool and Die...scroll down here

https://cuttermasters.com/about-us-2/?currency=CAD) and that they usually fix the machines for free:

https://cuttermasters.com/about-us-2/. The whole thing just seems way off.

Conquest (Cuttermaster) is still in business, has a 40,000 sq ft with 11 CNC machines (according to the website) but does not list tool grinders as a product.

Anyway,I ended up with a Chevlair bench top grinder, a clone of the real (orginal US) Cuttermaster with the column. It's a substantial and well balanced machine. It was 1500 used from a dealer 10 years ago and if you see one come up, I'd recommend it. They do on kijiji and at auction occasionally. Hienman in Miss, a good sized distributor sold a lot of them (according to the old boy Hienman himself when I asked him).

Chevelair are made in Tiawan and somewhere between ok and good imo. That view is mostly from working on/with the floor model I reconditioned (ok), and I would say benchtop is better made (good). The floor model, has received a ground reconditioning (scraping), really performs well now, but there were a few things about that make you shake your head. If I hold my tongue just so, I can grind a cylinder to less than tenth error, as measured with an indicating mic

In the age of the insert, its tough to be in the tool and cutter grinder business. It looks like Cuttermaster is gone, and Chevalier has dropped the the T&CGs. Sign of the times I guess.

original Cuttermaster manual - note url, no "s"

View attachment 21116

Accusize's claim

View attachment 21117

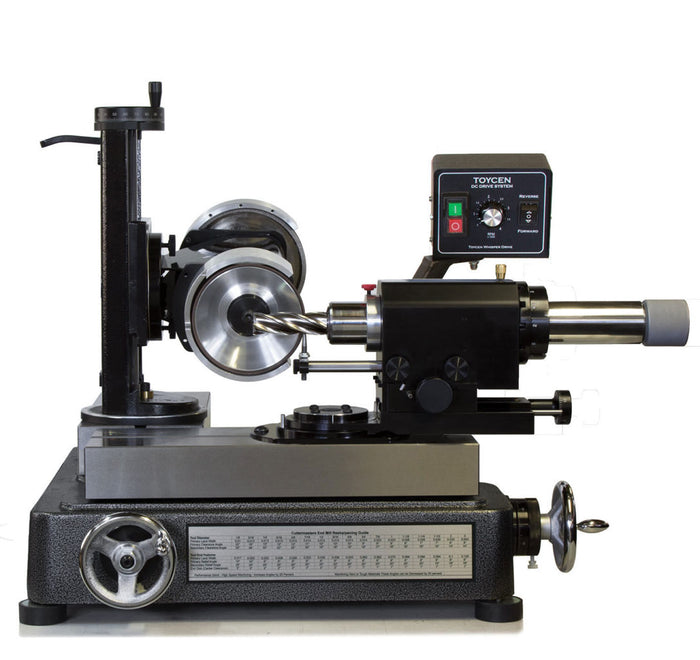

current Cuttermasters

my little Chevalair FCG-610

View attachment 21119

larger floor model chevalier...used a lot for cylindrical grinding - basically a knock off of a K O Less T&CG

View attachment 21118

View attachment 21120

]