I wish they did offer that sharpener!I am contemplating one of those mag drills, looks like i could find uses on the farm for it. Vevor has had some good reviews on their tools, the drill sharpener for onewhich is not on the web site.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DavidR8's shop shenanigans

- Thread starter David

- Start date

Yes it's a total Fein knock-off.

Here we go again......

Your link takes me to $263 not $226. That's not a bad price either but gee wilikers...... It almost seems like the whole world knows what I'm interested in......

Have you tried it yet David?

Sorry John I had the prices mixed up with another for $226 but I wanted variable speed so went with the $262 version.Here we go again......

Your link takes me to $263 not $226. That's not a bad price either but gee wilikers...... It almost seems like the whole world knows what I'm interested in......

View attachment 39457

Have you tried it yet David?

I haven't tried it yet because I need some coolant but I have fired it up. Not the quietest thing ever but the magnet is insanely strong.

Sorry John I had the prices mixed up with another for $226 but I wanted variable speed so went with the $262 version.

I haven't tried it yet but I have fired it up. Not the quietest thing ever but the magnet is insanely strong.

No sweat David. I'd prolly pay the extra for variable speed too. Especially for 2" holes!

Is the optional drive 3/4" Weldon? If so, I could use my existing annular cutters.

Yes, it's 3/4" Weldon with an included drill chuck to Weldon adapter.No sweat David. I'd prolly pay the extra for variable speed too. Especially for 2" holes!

Is the optional drive 3/4" Weldon? If so, I could use my existing annular cutters.

Dan Dubeau

Ultra Member

I might pick one up too. Going to need one to finish the sawmill. I figured I would have stumbled upon one on marketplace by now, but it's been slim pickens for a while.

I am super impressed by it. Definitely get the variable speed version.I might pick one up too. Going to need one to finish the sawmill. I figured I would have stumbled upon one on marketplace by now, but it's been slim pickens for a while.

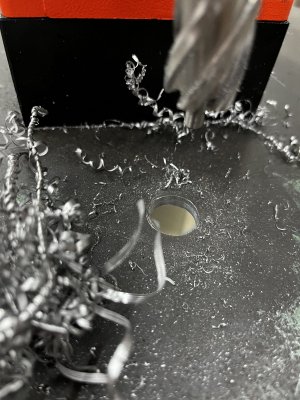

Couple of observations about the drill.

Bear in mind I have never used a mag drill or annular cutters before.

When the cutter breaks through the bottom surface there was a pretty good pop or bang as the slug was ejected. I didn't get the same feedback as a twist drill so it was difficult to judge when to ease up on the feed pressure. Likely more use will fine tune my senses with it.

Second, (and I knew this), the surface the drill sits on make a really big difference to its holding power.

On the 3/16 plate at the headstock end there was no way I could move it once the magnet was activated. On the 3x3x3/16 tube the base overhung the sides of the tube by maybe 1/4"-5/16". If I used a lot of feed pressure, it would tip back on the rear edge of the base. I suspect that if there was no overhang it would be fine.

Bear in mind I have never used a mag drill or annular cutters before.

When the cutter breaks through the bottom surface there was a pretty good pop or bang as the slug was ejected. I didn't get the same feedback as a twist drill so it was difficult to judge when to ease up on the feed pressure. Likely more use will fine tune my senses with it.

Second, (and I knew this), the surface the drill sits on make a really big difference to its holding power.

On the 3/16 plate at the headstock end there was no way I could move it once the magnet was activated. On the 3x3x3/16 tube the base overhung the sides of the tube by maybe 1/4"-5/16". If I used a lot of feed pressure, it would tip back on the rear edge of the base. I suspect that if there was no overhang it would be fine.

When the cutter breaks through the bottom surface there was a pretty good pop or bang as the slug was ejected. I didn't get the same feedback as a twist drill so it was difficult to judge when to ease up on the feed pressure. Likely more use will fine tune my senses with it.

I use annular cutters from time to time on my mill and I've even used them on my drill press a few times. They don't cut like a hole saw or a drill bit. I think your "pop" is pretty typical. It has never been a problem but I do try to control the down pressure so it doesn't get away from me. My vise and those cutters are expensive.

The first time it happened I hit the off button immediately and inspected the cutter thinking I broke off a tooth!I use annular cutters from time to time on my mill and I've even used them on my drill press a few times. They don't cut like a hole saw or a drill bit. I think your "pop" is pretty typical. It has never been a problem but I do try to control the down pressure so it doesn't get away from me. My vise and those cutters are expensive.

Yup, I have all the pieces for the counter shaft rough cut to length. Waiting on some tooling (counterbore set and bottom tap) to get started.Thing of beauty, is the counter shaft bracket next?

Have you got the new shop drawn up yet?

No plans yet but we’re sorta set on ~20 x 30. That would represent a 33% increase in floor space. A lot depends on what the municipality will allow.

We learned that it has to be minimum of 4m from the house which is about 3 ft further forward than the current garage.

I’m ok with that as that will let me build bicycle storage and air compressor outside the shop

And we’re progressing with the garage/carriage house build.

Got the proposal from the designer today.

I have always loved the idea of a carriage house. It isn't a part of my dreams anymore, but if I was younger it would be.

They are doing everything they can to ensure that we don’t have to apply for a variance.

I sincerely hope that they succeed!