-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DavidR8's shop shenanigans

- Thread starter David

- Start date

I think I'm going to spring for the MIG180.

Also does aluminum via a spool gun. That could be handy.

I have one, but my opinion of whether or not it is a good welder is not worth squat. I have managed to join a few things with it mostly by sheer luck.

Then again, it's ability to join anything when used by a welding idiot is a good testiment to its idiot proof design.

Dan Dubeau

Ultra Member

You will really like the upgrade. I went from a 140 Hobart to a 180c Lincoln, and I can't go back to a smaller machine now. The bigger one is so much more versatile. I wish I still had it (gave it to a friend), and kept it loaded with 0.023 for sheet metal, but as a primary machine for the stuff I do mostly, it was too small.

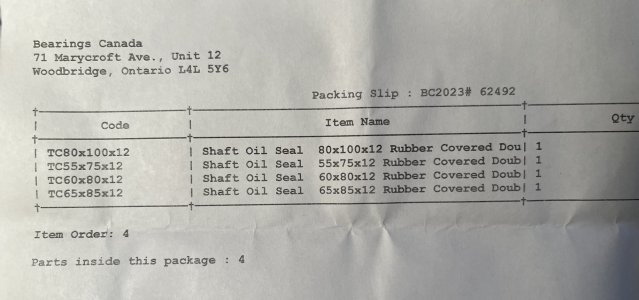

YAY! can you post the details? I may be in the market... soon...We’ve got seals!

YAY! can you post the details? I may be in the market... soon...

Attachments

Awesome. Everyone needs high quality seals.

Try it out for a while. Some guys love MIG aluminum (I'm one) but far more hate it. It is very tricky to get good penetration with excellent weld quality in MIG aluminum. Getting enough cleaning balance without overheating your tip an welding the wire to the tip can be a challenge. Even more than TIG, the material has to be spotlessly clean before using a MIG to weld aluminum.I rarely TIG steel but one of the reasons I bought it was to TIG aluminum.

- For me learning to TIG has been a struggle, and my aluminum MIG welds are better. My welds will never pass professional muster, but they do the job that I need to do,

So after doing ten feet or more of beads on the spool gun, you might find that you might really need to keep the TIG, or not.

No burning need to sell it and the new machine is actually smaller than the Miller so that's a plus.If you have no reason to sell it and have room to keep it, I would keep it. That will give you time to figure out "if" you need to sell it.

To be perfectly honest my TIG time can be counted in a small, single digit hour count whereas my MIG time is in the dozens of hours. That's likely the same as for most home gamers like me.Try it out for a while. Some guys love MIG aluminum (I'm one) but far more hate it. It is very tricky to get good penetration with excellent weld quality in MIG aluminum. Getting enough cleaning balance without overheating your tip an welding the wire to the tip can be a challenge. Even more than TIG, the material has to be spotlessly clean before using a MIG to weld aluminum.

- For me learning to TIG has been a struggle, and my aluminum MIG welds are better. My welds will never pass professional muster, but they do the job that I need to do,

So after doing ten feet or more of beads on the spool gun, you might find that you might really need to keep the TIG, or not.

I'll see how it goes. I actually find TIG'ing aluminum easier than steel. Not sure why. I'm curious about trying the spool gun.

I'm curious about trying the spool gun.

Keeping in mind my boy wonder welding skills.....

I hate my spool gun. Way too much "stuff" to hold while I'm trying to see what I'm doing through a welding Helmut. I no like.

They say aluminium wire won't feed through a regular length cable. But is that REALLY TRUE? Or is it more like: won't feed through a cable that twists all over the place like a drunken snake orgy?

I have not tried any welding since my stroke. That gun was bad enough with 2 eyes. I can only imagine what it will be like with only one eye.

They say aluminium wire won't feed through a regular length cable. But is that REALLY TRUE?

The stiffer grade of aluminum wire feeds through my short cable just fine. I recently bought a spool gun with John N, but haven't hooked it up yet. ALL my aluminum MIG welding has been through the normal feeding means. But on that welder the total cable length is about 5 feet, Teflon lined, and appropriately sized.

How it happened is this: I needed to do a lot of aluminum welding for a project in about '83... I bought a ClarkeWeld, an inexpensive offshore welder and a spool of aluminum wire. The guy at the welding shop told me it wouldn't work. At all. (I knew a guy once that was stubborn and pig-headed. it wasn't me - oh look, a squirrel!)

So without know anything about aluminum welding, and nothing about polarity or cleaning, I proceeded to make attempt after attempt until I got really strong, terrible looking welds in 6061T4 tubing. It got the job done. Since then I've dome a fair bit of aluminum welding, but all of it would make the good welders here on the forum cringe. but the welds all have decent penetration, are strong and the mess grinds away like any other weld.

We would use a teflon/plastic? lined liner for aluminum mig welding, with a different feeder wheel on the drive. This was pushing the wire thru 12-15 feet of cable. This liner was changed out for a regular liner when running wire for steel/cast iron welding. We did not want cross contamination. The aluminum liner sometimes had to be changed a bit more then the others, due to wear.

Check for sharp bends, Knicks, and break down of cable where cable leaves the welder at the connector and at the hand grip where cable enters grip. Watch out for a knicked liner also, remember, if you can't push the wire thru the cable by hand, the feeder can't do it either unless you have a push/pull system.

A lot of shops have gone to mig welding aluminum, tig is maybe? a slowly dying art in aluminum

Check for sharp bends, Knicks, and break down of cable where cable leaves the welder at the connector and at the hand grip where cable enters grip. Watch out for a knicked liner also, remember, if you can't push the wire thru the cable by hand, the feeder can't do it either unless you have a push/pull system.

A lot of shops have gone to mig welding aluminum, tig is maybe? a slowly dying art in aluminum

Working on a bathroom renovation.

This marks the sixth bathroom I’ve done and the part that always vexes me is removing the blasted drain.

While at the local hardware store picking up supplies I noticed this drain wrench.

1/2” drive, spiral grooves that dig in counter clockwise.

A few whacks to seat it and a 24” breaker bar and presto, out it came.

Highly recommended tool.

This marks the sixth bathroom I’ve done and the part that always vexes me is removing the blasted drain.

While at the local hardware store picking up supplies I noticed this drain wrench.

1/2” drive, spiral grooves that dig in counter clockwise.

A few whacks to seat it and a 24” breaker bar and presto, out it came.

Highly recommended tool.

Attachments

140mower

Don

...... you know, there's help groups out there that can guide you out of situations of self harmThis marks the sixth bathroom I’ve done

For those who are allergic to thinset, this works great for back splashes. Not sure about wet areas but we used it 15 years ago and the tile is still on the wall.

I've peeled tile off with out damaging the drywall as well, you just need to remove the grout first.

I've peeled tile off with out damaging the drywall as well, you just need to remove the grout first.