That looks pretty good. Look what you can do with chunky bar stock LOL. Consider drilling dowel pin holes which do primary alignment & provide rigidity. The recessed bolts or whatever basically provide retention but alignment can get loosey-goosey with fasteners only due to thread hole clearance. I've also seen some fixtures put together with dowels or even roll pins as temporary fixturing if the the plan was to weld and/or re-machine certain surfaces post welding if dimensions are more critical. Depending on how concentrically accurate your holes need to be, maybe consider doing that op on the finished assembly rather than risk misalignment unless you have other ways to fudge whatever is going into the holes.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DavidR8's shop shenanigans

- Thread starter David

- Start date

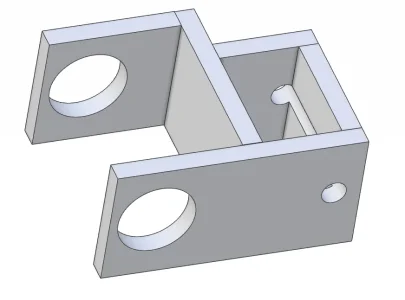

I found the perfect cap screw for you to use to hold it all together.@Dabbler Is this along the lines of what you were thinking?

(totally rough, no cap screws shown)

View attachment 38167

Former Member

Guest

I have brazed some stuff before with oxy-acet. Ok-ish, its a heat issue along with lack of understanding at the time (I was in grade 7 shop class, good old days when the kids got to play with dangerous $#!+ and actually learn something hands on).

Now I would suggest TIG it using either SS filler for cast or brazing filler. I have tried both, just because, and will tell you SS is a stronger joint but requires a little better heat control before during and after. Brazing, well TIG wands give heat (very controllable heat) so getting everything warm enough along with flowing the brazing filler is a lot easier (think hotter soldering). Big secret is cleaning before hand.

There are a few YouTube videos regarding this. (Its also the reason I have standard filler, SS filler and brazing filler and AL filler).

Final hint I would likely use an AL disc (turned to size) as the place holder for all the lose broken parts to get fitment.

Now I would suggest TIG it using either SS filler for cast or brazing filler. I have tried both, just because, and will tell you SS is a stronger joint but requires a little better heat control before during and after. Brazing, well TIG wands give heat (very controllable heat) so getting everything warm enough along with flowing the brazing filler is a lot easier (think hotter soldering). Big secret is cleaning before hand.

There are a few YouTube videos regarding this. (Its also the reason I have standard filler, SS filler and brazing filler and AL filler).

Final hint I would likely use an AL disc (turned to size) as the place holder for all the lose broken parts to get fitment.

Pins are a good idea.That looks pretty good. Look what you can do with chunky bar stock LOL. Consider drilling dowel pin holes which do primary alignment & provide rigidity. The recessed bolts or whatever basically provide retention but alignment can get loosey-goosey with fasteners only due to thread hole clearance. I've also seen some fixtures put together with dowels or even roll pins as temporary fixturing if the the plan was to weld and/or re-machine certain surfaces post welding if dimensions are more critical. Depending on how concentrically accurate your holes need to be, maybe consider doing that op on the finished assembly rather than risk misalignment unless you have other ways to fudge whatever is going into the holes.

My plan at this point is to bore the holes undersize, assemble the entire piece and then line bore on my Clausing.

Last edited:

Exactly. +1 on dowel pins: 2 per side. If you have a hydraultic press, drill and ream for press fit after putting in the cap screws and then press the pins for the money.@Dabbler Is this along the lines of what you were thinking?

This is true overkill in the grand tradition fo all hobby machine shops. The load on the bearing side is around 60 lbs on any one belt, and these 2 loads are 90 degrees apart. the load on the pivot pin is around 130 lbs force there is a torsional component as the cam is only on 1 side. That load will try to twist the bearing seats out of alignment... I'll work out the loads, but this looks more than rigid enough for that too.

Last edited:

Pins are a good idea.

My plan at this point is to bore the holes undersize, assemble the entire piece and then like bore on my Clausing.

Another thing I sometimes do when I repair farm equipment is to make the part out of blocks the way you did, and then use epoxy to put it together using the epoxy like welding on the seams and then cure in place. Then I can drill, pin, tap, and bolt the final cured assembly together. A little epoxy in the assembly never hurts anyway, and if the matching parts are not aligned perfectly, the epoxied matching part reflects that which is USUALLY a good thing.

Thanks John, I’ve been mulling over how to hold the various pieces together while drilling and assembling. Great idea!Another thing I sometimes do when I repair farm equipment is to make the part out of blocks the way you did, and then use epoxy to put it together using the epoxy like welding on the seams and then cure in place. Then I can drill, pin, tap, and bolt the final cured assembly together. A little epoxy in the assembly never hurts anyway, and if the matching parts are not aligned perfectly, the epoxied matching part reflects that which is USUALLY a good thing.

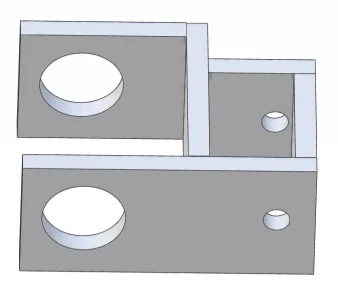

Here's my re-draw with accurate dimensions taken from the part.

The edge to edge distance on the holes is 76 mm. The bearing bore is 47mm, the pivot bore is 15mm.

I put the bearing bore 5mm from the front and the pivot bore partially interferes with the rear plate.

How critical is the distance between them. If I bring the pivot forward another 5-7mm will it make any difference?

I think I recall you said that the over all length of ~6" is somewhat critical but I can't remember.

Last edited:

I put the bearing bore 5mm from the front and the pivot bore partially interferes with the rear plate.

How critical is the distance between them. If I bring the pivot forward another 5-7mm will it make any difference?

Why worry about it?

Mill a channel in the rear plate to accommodate the pivot. Could be round or square. A square channel will not create stress risers because there is no flex load that I know of and even if there was, the side plates will do that work. Even a thin remaining cross-section (say 1/8th) will be strong enough for your needs as long as there are 4 bolts (one in each corner) and 2 or 4 pins. The web's primary function is to maintain dimension.

Maintaining the bearing centreline to pivot centreline distance allows you to use the same vee belt, and will end up in a similar adjustment range.I think I recall you said that the over all length of ~6" is somewhat critical but I can't remember.

I'll measure the clearances of the assembled shaft with pulleys, as you will need to sue the mill or lathe to remove metal to for a boss on one or both sides to allow room for the pulley flanges. A photograph and some dimension will be a lot clearer. I'll do that later today.

Last edited:

Left, yes a milled clearance trough would do the trick.

Center, if you can avoid the clearance altogether by altering dimensions like first version, life would be simpler.

Right, or if you box it in with side members (thus no clearance trough), does that help with rigidity or accessibility?

Center, if you can avoid the clearance altogether by altering dimensions like first version, life would be simpler.

Right, or if you box it in with side members (thus no clearance trough), does that help with rigidity or accessibility?

... but, but.... there is lots of clearance behind the plate that is suggested to be milled... like more than an inch.

I'm not too sure what is gained by making the pivot-jackshaft distance 5mm shorter. Is it an issue with materials you purchased? It means the angle of the assembly that tensions the belt will have to be greater. I'll check what the clearance is between the largest pulley and the back of the headstock. There might be lots, there might be minimal. Pictures to follow.

I'm not too sure what is gained by making the pivot-jackshaft distance 5mm shorter. Is it an issue with materials you purchased? It means the angle of the assembly that tensions the belt will have to be greater. I'll check what the clearance is between the largest pulley and the back of the headstock. There might be lots, there might be minimal. Pictures to follow.

RobinHood

Ultra Member

I would make the main yoke from a continuous piece of your 1/2” HR bar. Just bend it in the correct places. Then weld in the cross brace. If you can’t bend it on a press, use OA. If you don’t have OA, cut 45* grooves (bevels) almost through the plate at the correct places, bend in the vise and weld back together.

Saves you all kinds of alignment problems (no pins required) because of not having individual pieces.

Locate the holes and drill / bore to size as a last step.

Saves you all kinds of alignment problems (no pins required) because of not having individual pieces.

Locate the holes and drill / bore to size as a last step.

No issue with the materials.... but, but.... there is lots of clearance behind the plate that is suggested to be milled... like more than an inch.

I'm not too sure what is gained by making the pivot-jackshaft distance 5mm shorter. Is it an issue with materials you purchased? It means the angle of the assembly that tensions the belt will have to be greater. I'll check what the clearance is between the largest pulley and the back of the headstock. There might be lots, there might be minimal. Pictures to follow.

I made a measuring mistake. The piece is 6.5" long not 6" as I drew it. That changes everything as it allows for clearance.

I love this idea, I might have to try on a sample to see how good I can get the angles.I would make the main yoke from a continuous piece of your 1/2” HR bar. Just bend it in the correct places. Then weld in the cross brace. If you can’t bend it on a press, use OA. If you don’t have OA, cut 45* grooves (bevels) almost through the plate at the correct places, bend in the vise and weld back together.

View attachment 38208

Saves you all kinds of alignment problems (no pins required) because of not having individual pieces.

Locate the holes and drill / bore to size as a last step.

The whole casting is maybe 3/8” thick except for back section and where the bearings are. The cross brace is about 1/4” thick.Does the entire bracket need to be 1/2" or just the bearing and pivot area?