I started reading and looking at machines. There are a LOT of variations and technologies & prices. David could you please sum up the options briefly on Diode vs CO2. Also it seems to me the laser power is one thing but another is laser power per unit of square area. For example on that Longer Ray 5 10W machine above they list specs on different models. It turns out the 10W machine has power of 2700W/mm^2 yet paradoxically the 20W version is 2500W/mm^2. The laser focal size on the 10W is much smaller. I'm not sure how important that detail is in practical performance.

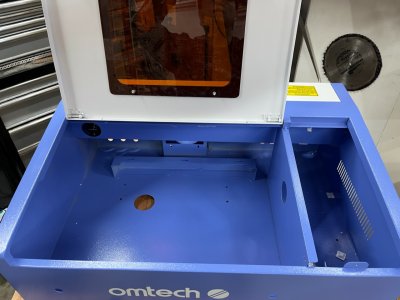

You are buying a CO2 laser - what made you decide that?

You are buying a CO2 laser - what made you decide that?