The #38 spring is to preload the cam, so the assembly doesn’t flop around too much when the #11 arm is released. For mine, I have the spring between #36 and #31. I think a spring in both locations would be an advantage.@whydontu If I understand correctly, I think the CX706 already has such a spring. See the following:

View attachment 42751

It doesn't show very well, but the spring (#38) and washer go on top of the clamping plate ((#36). I wondered if the spring was really necessary but I guess your experience suggests it is?

Craig

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Craig's Craftex CX706 Comes Clean

- Thread starter trlvn

- Start date

trlvn

Ultra Member

One of my 'maybe-one-day' plans has been to add a collet chuck to this lathe. Finding the correct backing plate to adapt from the spindle nose to the chuck has stymied me. Previously.

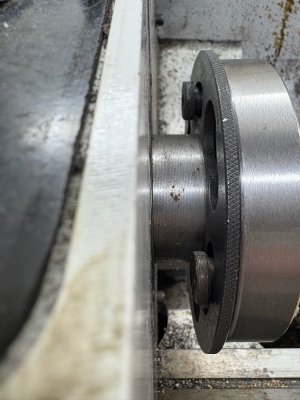

BusyBee, in their Christmas in July sale, was offering an adaptor plate for the CX615 (lathe/mill combo machine). It turns out it also fits my CX706 (10 X 22). Here are 2 views of it on my lathe:

I found that the threaded holes for the mounting studs are different. The CX706 chucks come with M10 threaded studs but the pre-drilled holes in this adaptor plate are M8. I've use a simple M8 bolt as a mock-up above. The adaptor plate does not come with any mounting studs at all.

To work around this, the adaptor plate could be drilled out and re-threaded for M10. Or, I could make a custom set of studs with M8 on one side and M10 on the other. I think I'll go the latter direction since I'm going to need studs anyway.

For comparison, the picture below is the CX615 plate compared to the CX706 face plate.

I paid $127 plus HST for the plate but the sale ends tomorrow (August 3, 2025) when it will go back up by over $30. I probably could have gotten a slice of Durabar for maybe a little less money. It would not have been easy to handle on a machine of my size.

Now I can start looking for a decent collet chuck!

Craig

(Also attached a couple of picture of the bare spindle nose for those curious.)

BusyBee, in their Christmas in July sale, was offering an adaptor plate for the CX615 (lathe/mill combo machine). It turns out it also fits my CX706 (10 X 22). Here are 2 views of it on my lathe:

I found that the threaded holes for the mounting studs are different. The CX706 chucks come with M10 threaded studs but the pre-drilled holes in this adaptor plate are M8. I've use a simple M8 bolt as a mock-up above. The adaptor plate does not come with any mounting studs at all.

To work around this, the adaptor plate could be drilled out and re-threaded for M10. Or, I could make a custom set of studs with M8 on one side and M10 on the other. I think I'll go the latter direction since I'm going to need studs anyway.

For comparison, the picture below is the CX615 plate compared to the CX706 face plate.

I paid $127 plus HST for the plate but the sale ends tomorrow (August 3, 2025) when it will go back up by over $30. I probably could have gotten a slice of Durabar for maybe a little less money. It would not have been easy to handle on a machine of my size.

Now I can start looking for a decent collet chuck!

Craig

(Also attached a couple of picture of the bare spindle nose for those curious.)

Attachments

Proxule

Ultra Member

Nice work. I opted for an aliexpress chuck and a amazon D1-4 backing plate.

I have if memory serves me right - 0.005mm TIR. Or was that .001mm....

Here is the link for the collet chuck. quality is top notch for 70$ shipped !

I just found this on AliExpress:

C$18.78 | ER16 ER50 ER25 ER32 125 ER40 chuck 100mm 80mm Mini Flange Four Axis cartridge Collet Fixture Chuck For CNC Milling Lathe Tool

a.aliexpress.com

a.aliexpress.com

The register on my backing plate was machined for a snug fit and thus my TIR is superb. 1 project done. 93748 left lol.

Gluck to you !

I have if memory serves me right - 0.005mm TIR. Or was that .001mm....

Here is the link for the collet chuck. quality is top notch for 70$ shipped !

I just found this on AliExpress:

C$18.78 | ER16 ER50 ER25 ER32 125 ER40 chuck 100mm 80mm Mini Flange Four Axis cartridge Collet Fixture Chuck For CNC Milling Lathe Tool

ER16 ER50 ER25 ER32 125 ER40 chuck 100mm 80mm Mini Flange Four Axis cartridge Collet Fixture Chuck For CNC Milling Lathe Tool

Smarter Shopping, Better Living! Aliexpress.com

The register on my backing plate was machined for a snug fit and thus my TIR is superb. 1 project done. 93748 left lol.

Gluck to you !

Now I can start looking for a decent collet chuck!

Nice progress!

Before you get too far down the road you should try to decide if you want a 5C chuck or an ER and if the latter, then what size?

DPittman

Ultra Member

Well you can easily add a morse taper collet holder at any point.Nice progress!

Before you get too far down the road you should try to decide if you want a 5C chuck or an ER and if the latter, then what size?

trlvn

Ultra Member

Can you link to an example? My spindle taper is MT4 so won't hold a 5C collet inside...Well you can easily add a morse taper collet holder at any point.

Craig

DPittman

Ultra Member

This is a MT3 one off Amazon.Can you link to an example? My spindle taper is MT4 so won't hold a 5C collet inside...

Craig

Acouto Er32 Collet Set T3 Er32 MTA3 Morse Taper Collet Chuck Holder Carbon Steel CNC Milling Lathe Parts M12 for Milling Chuck : Amazon.ca: Tools & Home Improvement

Acouto Er32 Collet Set T3 Er32 MTA3 Morse Taper Collet Chuck Holder Carbon Steel CNC Milling Lathe Parts M12 for Milling Chuck : Amazon.ca: Tools & Home Improvement

a.co

MT3 tends to be popular but I imagine MT4 is available too. Ali Express is also a good place for such.

DPittman

Ultra Member

Sorry i should have put a bit more effort into looking for a better link for you. My excuse is I'm distracted.This is a MT3 one off Amazon.

Acouto Er32 Collet Set T3 Er32 MTA3 Morse Taper Collet Chuck Holder Carbon Steel CNC Milling Lathe Parts M12 for Milling Chuck : Amazon.ca: Tools & Home Improvement

Acouto Er32 Collet Set T3 Er32 MTA3 Morse Taper Collet Chuck Holder Carbon Steel CNC Milling Lathe Parts M12 for Milling Chuck : Amazon.ca: Tools & Home Improvementa.co

MT3 tends to be popular but I imagine MT4 is available too. Ali Express is also a good place for such.

Acouto Er32 Collet Set T3 Er32 MTA3 Morse Taper Collet Chuck Holder Carbon Steel CNC Milling Lathe Parts M12 for Milling Chuck : Amazon.ca: Tools & Home Improvement

Acouto Er32 Collet Set T3 Er32 MTA3 Morse Taper Collet Chuck Holder Carbon Steel CNC Milling Lathe Parts M12 for Milling Chuck : Amazon.ca: Tools & Home Improvement

a.co

I'm leaning more toward a 5C chuck. I have a good range of 5C collets already and I would really hate to duplicate all those sizes in ER.

Craig

That's what I have and I love it. You have prolly heard me say that my 5C Collet chuck lives on my lathe more than all my other chucks combined.

As you prolly know, the 5C is best done with a full collet chuck that handles the 5C collet threads directly. Ya, you can do a custom MT4 collet holder but then you need a drawbar. It's just easier with a chuck.

If you decide you want an ER system later, you can adapt a drawbar for the holder and then just use the collet nut when changing collets.

If you already have the 5C collets, it's just a matter of adding the chuck which is where you were when you started this thread....

Throwing up distractions is one of my worst character flaws. Sorry about that... .