trlvn

Ultra Member

Some of you may remember that I started searching seriously for a new lathe in the 10-11" swing range a couple of months ago:

canadianhobbymetalworkers.com

canadianhobbymetalworkers.com

I'm happy to report that my new Craftex CX706 10 X 22 lathe arrived safely this week. At Busybee in Mississauga, they forklifted it into the van I'd rented. My son and I slide it down some 2X6's into the garage. They say the gross weight is 160 kg (352 pounds) but it sure felt like more. In the garaage, I opened up the crate and pulled out the parts that could be carried separately--2 chucks, face plate, tailstock, tools, etc.

I planned to use a 2-wheel cart to move the machine to the basement. In hindsight, renting a proper appliance dolly would have made it slightly easier. I decided to leave the machine bolted to the base of the crate for the move since it was otherwise going to be very difficult to strap it to the cart. In any event, my son, my daughter and I got it down the stairs (including a right-angle turn) and into the basement. Only my son got his fingers pinched when we lifted it off the crate base and onto the bench*.

Not that I also took the backsplash and gear train covers off for the move. The gear train cover is just held in place by a couple of small studs--no where near strong enough to be a lifting point. I was concerned the backsplash was going to make it more difficult to maneuver down the stairs and again it is not strong enough to be a lifting point.

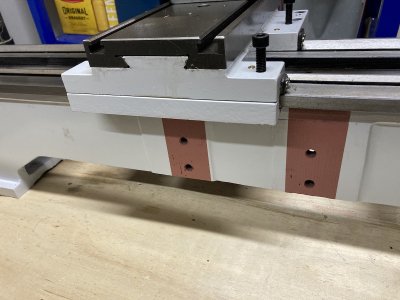

I've spent a fair bit of time cleaning and lubing my new toys. Disassembled both chucks; the 4-jaw had a large metal chip fouling one of the screws. In the picture below, you can see some of the grit and dirty oil that was on the machine. I disassembled, cleaned and lubed both the compound and the cross slide. After adjusting the gibs, I think the operation is pretty smooth.

I wanted to take the gears off the banjo to clean and lube but I've put that off for now. There was a Blondihacks video where she noted that the gears on her Precision Matthews lathe were and extremely tight to the studs to begin with. I believe she used a reamer to ensure the hole in each gear was a good fit. That would require a 14mm reamer (ideally spiral) which I don't have. May need to buy one.

I'm also debating about changing the oil in the headstock and apron. Now or wait until I've used it for a few months?

The next step is to retrieve the QCTP I ordered. I had it delivered to a service just across the border in New York. This will be my first crossing since the pandemic started. Fingers crossed that it goes OK. BTW, I'm 90% certain that I'll have to modify the compound slightly to fit the QCTP. The tool post that comes with it sits on a boss that sticks up too high. Should be no big deal to mill it down.

I also want to try taking some measurements. I've ordered a test bar from India and the tracking says it will be here in 3 days.

Or course, I've played with the controls a bit. All the basic functions seem to work OK. The two knobs on the front (left-right travel and A-B-C feed speeds) don't give good feedback that they're engaged. Also, the lever is quite stiff going from longitudinal to crossfeed modes. I know you don't want to do by accident but it seems pretty sticky.

Craig

* No fingers were permanently harmed in the moving of the lathe.

10-11 inch lathes -- Precision Matthews, Modern Tool

Hi: I'm edging toward upgrading from my tiny, beat-up Atlas 618 lathe and I thought I'd ask for input about new lathes. Whatever I choose has to go down the basement stairs, including a 90 degree corner, and into the available space which is ideally 51 inches or maximally about 60 inches...

I'm happy to report that my new Craftex CX706 10 X 22 lathe arrived safely this week. At Busybee in Mississauga, they forklifted it into the van I'd rented. My son and I slide it down some 2X6's into the garage. They say the gross weight is 160 kg (352 pounds) but it sure felt like more. In the garaage, I opened up the crate and pulled out the parts that could be carried separately--2 chucks, face plate, tailstock, tools, etc.

I planned to use a 2-wheel cart to move the machine to the basement. In hindsight, renting a proper appliance dolly would have made it slightly easier. I decided to leave the machine bolted to the base of the crate for the move since it was otherwise going to be very difficult to strap it to the cart. In any event, my son, my daughter and I got it down the stairs (including a right-angle turn) and into the basement. Only my son got his fingers pinched when we lifted it off the crate base and onto the bench*.

Not that I also took the backsplash and gear train covers off for the move. The gear train cover is just held in place by a couple of small studs--no where near strong enough to be a lifting point. I was concerned the backsplash was going to make it more difficult to maneuver down the stairs and again it is not strong enough to be a lifting point.

I've spent a fair bit of time cleaning and lubing my new toys. Disassembled both chucks; the 4-jaw had a large metal chip fouling one of the screws. In the picture below, you can see some of the grit and dirty oil that was on the machine. I disassembled, cleaned and lubed both the compound and the cross slide. After adjusting the gibs, I think the operation is pretty smooth.

I wanted to take the gears off the banjo to clean and lube but I've put that off for now. There was a Blondihacks video where she noted that the gears on her Precision Matthews lathe were and extremely tight to the studs to begin with. I believe she used a reamer to ensure the hole in each gear was a good fit. That would require a 14mm reamer (ideally spiral) which I don't have. May need to buy one.

I'm also debating about changing the oil in the headstock and apron. Now or wait until I've used it for a few months?

The next step is to retrieve the QCTP I ordered. I had it delivered to a service just across the border in New York. This will be my first crossing since the pandemic started. Fingers crossed that it goes OK. BTW, I'm 90% certain that I'll have to modify the compound slightly to fit the QCTP. The tool post that comes with it sits on a boss that sticks up too high. Should be no big deal to mill it down.

I also want to try taking some measurements. I've ordered a test bar from India and the tracking says it will be here in 3 days.

Or course, I've played with the controls a bit. All the basic functions seem to work OK. The two knobs on the front (left-right travel and A-B-C feed speeds) don't give good feedback that they're engaged. Also, the lever is quite stiff going from longitudinal to crossfeed modes. I know you don't want to do by accident but it seems pretty sticky.

Craig

* No fingers were permanently harmed in the moving of the lathe.