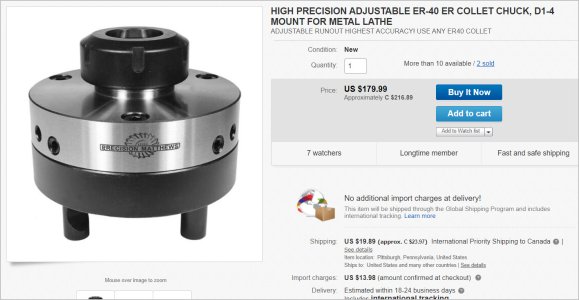

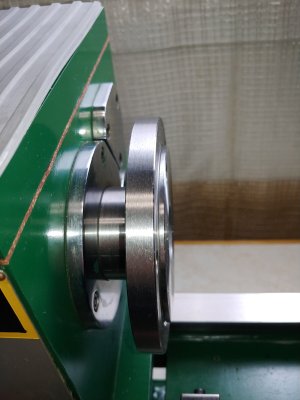

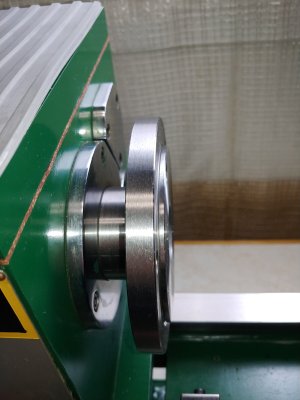

Doesn't work for Dusty's lathe, but looks like Precision Mathews sells an integrated D1-4 backplate / ER40 collet chuck on Ebay. And it has the equivalent of set-tru (adjustment screws) so can be dialed in independent of back plate adapter. (ebay item number 234016145577)

PM store home here

http://www.ebaystores.ca/Quality-Machine-Tools

PM store home here

http://www.ebaystores.ca/Quality-Machine-Tools

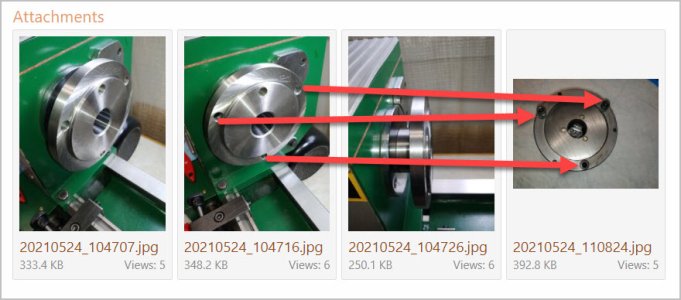

Attachments

Last edited: