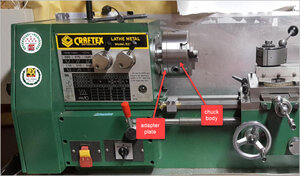

My lathe is a Craftex B2227L 10"x18", with a spindle bore of 27mm/1" and #4 Morse taper. Been thinking on getting a Collet chuck for my lathe although never used one before. Looking at the collet chuck listings on KBC I become totally confused from their data. CNC simply does NOT fit my wants or needs. Members with collet experience will surely catch my thinking here basically working with fractional collets up to 3/4".

Perhaps there's a member with an older no longer needed collet set that would fit my lathe. I'm sort of at a loss guys mostly due to the #4 Morse taper of my lathe. At this point I'm looking for specifics and suggestions to work my white matter through this' LOL

Bottom line, perhaps cost will keep my plan out of reach. Just saying!

Perhaps there's a member with an older no longer needed collet set that would fit my lathe. I'm sort of at a loss guys mostly due to the #4 Morse taper of my lathe. At this point I'm looking for specifics and suggestions to work my white matter through this' LOL

Bottom line, perhaps cost will keep my plan out of reach. Just saying!