Toolmaker's microscope...works great.Could be. Makes sense for an outfit like Starrett.

Holy shit. That Fkn thread is 78.5 thou x maybe 60 tpi. So probably an 80 thou #2 screw. Or perhaps a 2mm x 0.45 or or or.... Gunna need a better way to measure threads I can't see.

Clock makers? Any suggestions? My screw gauge is letting me down.

I suppose I could single point that but I'm not gunna. Just need to find a long screw whatever size that is!

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tool Caliper with broken screw

- Thread starter Susquatch

- Start date

Tool

ChazzC

Ultra Member

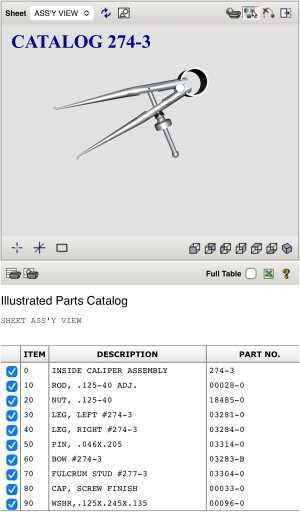

Per the exploded drawing & parts list in Post #5, it's 0.125-40. As I've noted elsewhere ( but maybe not on this forum until now) Starrett hasn't changed threads on these ancient tools to make them standard; in many cases the original toolmakers just used whatever they wanted, or made a tap to suit the single-pointed thread. I have a PT13820 "Upright Post, #196" that is (per Starrett) 0.231-28: I replicated it for a longer rod by using an adjustable 12-28 round die.Could be. Makes sense for an outfit like Starrett.

Holy shit. That Fkn thread is 78.5 thou x maybe 60 tpi. So probably an 80 thou #2 screw. Or perhaps a 2mm x 0.45 or or or.... Gunna need a better way to measure threads I can't see.

Clock makers? Any suggestions? My screw gauge is letting me down.

I suppose I could single point that but I'm not gunna. Just need to find a long screw whatever size that is!

If you have a good place you can go in person, take the thumbnut with you and try before you buy.

I only have Fastenal here and they are unlikely to have something like that. In any event, I have not been able to get the thumbwheel off yet. So your earlier suggestion to use a bigger screw is starting to look pretty good.

If you have to order, order a bunch of sizes and use the one that fits. (shipping will likely be the largest portion of cost)

Yes, my feelings exactly. I'd prolly also order more than one and save them for a future job anyway.

If none of them fit, see my post above.

Yup, looking more and more like that's the way to go.

Per the exploded drawing & parts list in Post #5, it's 0.125-40.

No way. Don't care what that reference says. That screw measures 0.0785 it's not even close to 0.125! It could be 40 tpi though.

Toolmaker's microscope...works great.

I don't have one of those. But I do have a nice biology microscope I could use. If all else fails, I'll count teeth - wouldn't be the first time I've done that!

140mower

Don

Whatcha mean? Everybody loves sex and travel......Ya, I deserved that. But I still have two words for you and they are not nice!

ChazzC

Ultra Member

Apparently Starrett changed the design of the legs to make them beefier; here is the current model:

Bet I know exactly why they did that! LOL!

ChazzC

Ultra Member

Wouldn’t happen to been that the screw was too weak?Bet I know exactly why they did that! LOL!

Wouldn’t happen to been that the screw was too weak?

Ya, it's a tiny little thing. That's prolly why mine broke.

My guess is it’s cheaper to make it from 1/8” mild steel that’ll bend than from a high grade steel that snaps.

You are prolly right, but I'm not really worried about it. It's a caliper, not a brake caliper bracket. I can't get my head around the Buffalo treatment the poor thing was subjected to. Prolly used it as a glue up clamp!

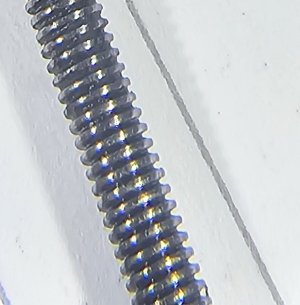

I have used a microscope at the lowest possible magnification. And I now believe that the screw is 60tpi. Recall that it is 0.0875" in diameter. The holes in the caliper body are 0.093 using a pin gauge. So that's the biggest screw I can use without enlarging the holes.

Now I need to figure out what that thread really is if I want to replace it without major modifications.

I should add that getting that thumb nut off was an ordeal. It wouldn't budge. I cleaned it in my ultrasonic tub. Then I soaked it in penetrating oil. No joy.

So I used a big pliers to hold the screw like a heat sink and heated the thumb screw slightly, then used a small plier to wiggle the nut. It moved! Yes! From thereon I applied lots of penetrating oil and wiggled it back and forth ever so gently about 15 degrees at a crack. With patience, I finally got it off using a tapping sequence. Plus 45, minus 30, plus 45, minus 30. It never did free up till I was all done.

Under the microscope, it looks like an ACME trapezoid thread. Kind of cool to see that so small. But I'd guess it's just deformation and not really ACME.

Any guesses?

Now I need to figure out what that thread really is if I want to replace it without major modifications.

I should add that getting that thumb nut off was an ordeal. It wouldn't budge. I cleaned it in my ultrasonic tub. Then I soaked it in penetrating oil. No joy.

So I used a big pliers to hold the screw like a heat sink and heated the thumb screw slightly, then used a small plier to wiggle the nut. It moved! Yes! From thereon I applied lots of penetrating oil and wiggled it back and forth ever so gently about 15 degrees at a crack. With patience, I finally got it off using a tapping sequence. Plus 45, minus 30, plus 45, minus 30. It never did free up till I was all done.

Under the microscope, it looks like an ACME trapezoid thread. Kind of cool to see that so small. But I'd guess it's just deformation and not really ACME.

Any guesses?

Hey, are you sure it's a Starrett? The thread almost looks like BA.

#8BA is 2.2mm OD (0.0866"), pitch 0.431mm (58.9 tpi)

Ok. Well, then, I guess it ain't a BA thread.

#8BA is 2.2mm OD (0.0866"), pitch 0.431mm (58.9 tpi)

Maybe. But it is Starrett. And odd to have an OD slightly bigger by 1 thou than spec. Usually they are smaller not bigger. But I'd guess I'd never be able to feel the difference between 58.9 and 60 tpi on a short nut.

Megar arc 5040dd

Super User

Do you intend on reusing the nut or making a new one? I have a pair of dividers that are missing an arched peace that goes between the 2 legs if you find you like repairing these. I think I have a pair of hermaphrodite calipers that is missing a piece also. should I sent them your way?