Not timely enough, I'm afraid. I could have given you everything you bought except the ball screw, including the tap (I have a lot of those, too), which you could have used to make the screw.

Oh, well. Next time, maybe.

Yes, you probably could have. But I had reached the point where I was either going to pitch it into the scrap pile or just get it done. So I ordered parts from MC on Wednesday, they arrived today (amazing really), and now I am done!

Well, almost done.......

Nice did you consider rounding the nose of the nut to fit better against the caliper leg?

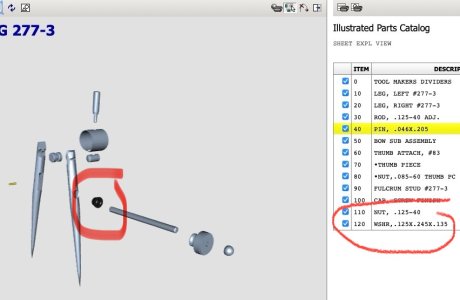

Not till you mentioned it. But I don't think I'll round off the nut. This is better.....

Mine

Nice guys, I can definitely make a little half round washer thingy to fit under the ball nut. Good idea to do that before I shorten the screw. Might be among the smallest things I ever made on my lathe though........ the titanium pin was prolly the smallest.