My turn. Being a new owner of a A1C+AMS it's been an interesting experience.

1. Is it turnkey? It was for me. Didn't even read the web directions which was probably a stupid move.

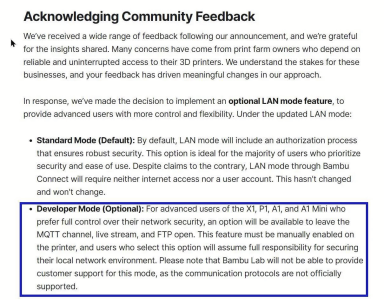

2. Is it like an APPLE product. Yes. Lot's of things to "enhance your user experience" but nowadays everyone is doing that.

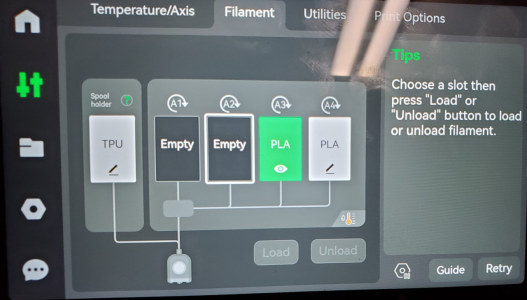

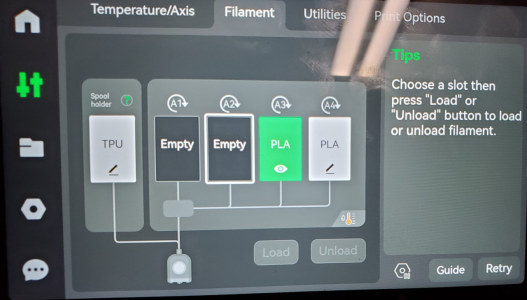

3. They supplied a spool with a small amount of green PLA Basic filament and a full spool of support filament. I used up the green.

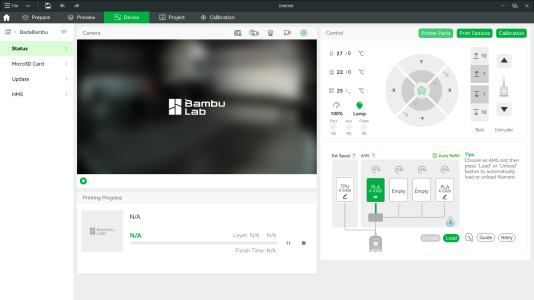

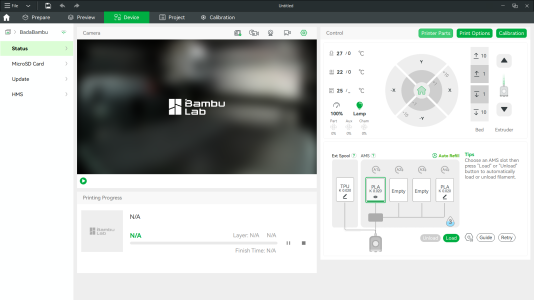

What happened though is when this spool is installed in the AMS and the filament pushed into the drive slot the reel comes to life, turns back and forth a bit and clearly the system reads the RFID tag because the display now shows it installed in A3. And in the user interface it sets up the slicing parameters for the best operation with the filament (as in really fast and still nice).

But wait... there's more. The grey plastic spool on the left had the green filament. The cardboard spool on the right is from Matter3D in Langford. Notice under the label there's a grey/silver dot covered in plastic. It runs across and is the same on the other side.

That first photo in this posting isn't from the left spool but from the cardboard one with the RFID tag. The system thinks it's green and it sets up printing as if it was the green Bambu PLA Basic.

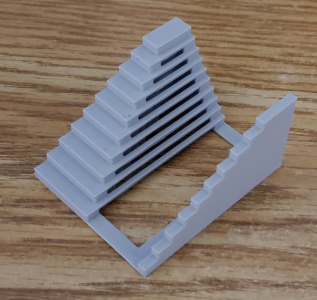

Now if this filament isn't as good as the Bambu then it's easy enough in the user interface to change speed and other parameters etc. So how does the grey turn out if the nozzle isn't all clogged from an odd PETG changeover experience?

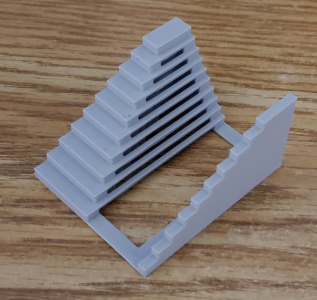

Really well. Dimensions match. Finish is good.

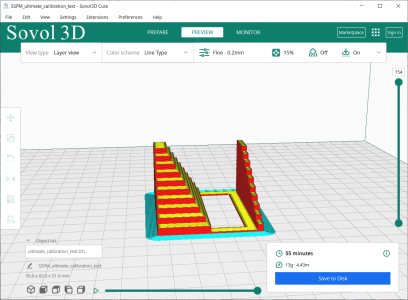

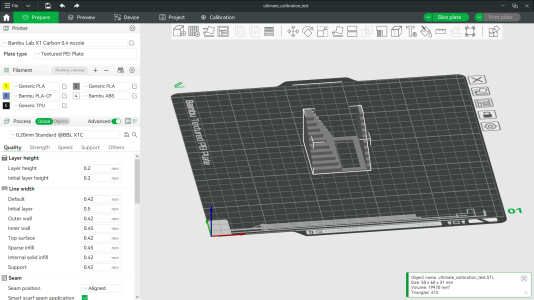

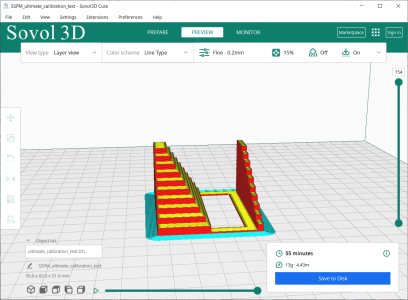

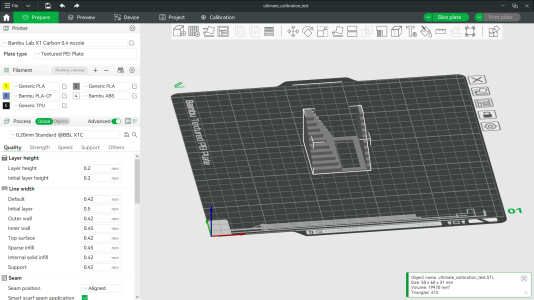

From the software perspective. Create a new project, import an STL file, highlight it on the build plate and select which reel to use. Slice and send to printer. It pops up with sending to printer through the cloud. It's already sliced so I'm not even sure why it has to go through the cloud but apparently that feature can be switched to not go through the cloud.

What it cannot do is import a G-Code file sliced by something else. That's probably why the ORCA slicer is an add on module.

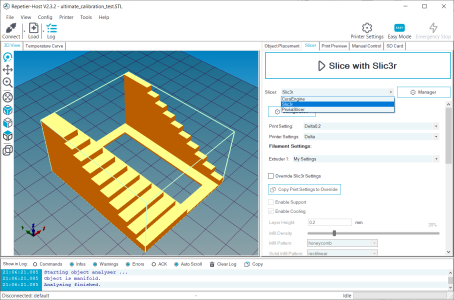

Let's take a step sideways for a moment. The way I used to do it and how I still do with the SOVOL since I don't have this 'klipper' thing on my SOVOL (

@DavidR8 has)

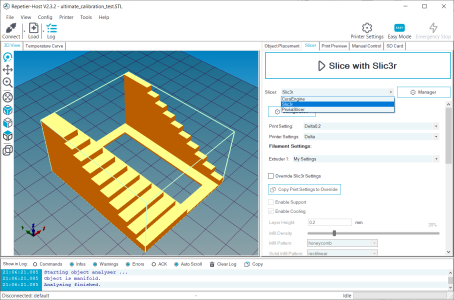

In the old days I used the Repetier_Host software and I could slice with any old slicer that created the G-Code. Most of the time I used Slic3r. The Repetier_Host could can connect via USB to the printer driver board and run the printer or just save to a file or SD card.

I do the same thing with the SOVOL program and save the sliced file to disk.

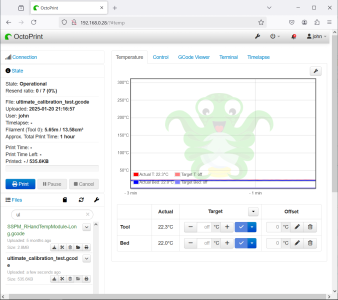

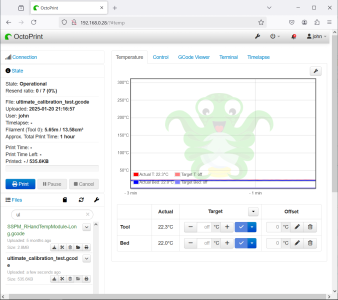

And now here is where things are different from the Bambu and I think the 'klipper' thing. For the SOVOL and the now defunct older printer I use a Raspberry Pi and a program called OctoPrint. It's on my network. I drag and drop the generated G-Code file onto the user interface and then tell it to print. The SOVOL Slicer or which ever one I've chosen on Repetier_Host has the printer configuration set up so the G-Code matches the printer.

The Raspberry Pi is connected to the SOVOL (or my old one) via USB again just like the PC could be with Repetier_Host. But now the printer can be far away in a closed room where the noise doesn't keep us awake and the connection display is done with the browser.

Plus the Pi has a camera so I can watch it too. I can even track each layer as it's being printed. It's graphically laid down in one colour and then as the printer lays down the filament the trace changes colour. There are also all sorts of features like

@DavidR8 will have to post some pictures to show what that 'klipper' thing does. How to slice. How to print. How to watch with video.

Am I disappointed that I can't use the same user interface for both the SOVOL and the BAMBU? Yes. But I knew that going in.

OTOH, The Bambu overall is easier to use if I didn't know anything. It's frustrating because I think the user interface is poorly written. Instead of clicking on the part and then way down clicking on change filament I should be able to select the filament from 5 locations on the main screen.

What's also awful is that although the user interface is theoretically in communications with the printer it doesn't know that I loaded new filament that is green. Or, it knows that the filament with that RFID tag has now been marked as grey (which it is).

In either case if I click on the yellow #1 for Generic PLA at a simple level I think the part on the build plate should turn yellow. The chance you'd have two different items on the build plate and go through a filament change for every layer is very unlikely. But that doesn't happen. the filament colours and types don't match the printer.

However from a project perspective if the project is loaded then it fills in what is required for this project. ie. instructions as to which type of filament to put into which AMS slot.

All for now.