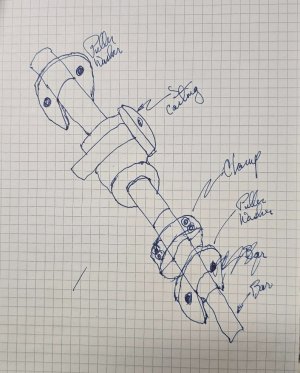

Here is the general idea:

The Fusion guys are prolly laughing, but this is my old fashioned 2D ballpoint pen cad system running with a few missing light bulbs.

Here is a 2" puller washer I made for an earlier project. It uses three puller bolts instead of two, but it's the same idea. By mounting the clamp on the bar at one end or the other, the S-Casting can be dragged in either direction just by tightening the puller bolts on the washers.

For this job, I'll make my own washers out of much thicker steel so I don't have to worry about them bending. The clamp and the casting should keep the washers from twisting or distorting. The spacing of the two Puller bolts will be set by the size of the casting.

Bedtime now.

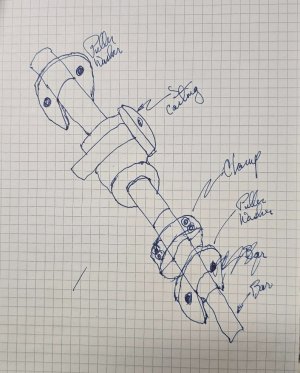

The Fusion guys are prolly laughing, but this is my old fashioned 2D ballpoint pen cad system running with a few missing light bulbs.

Here is a 2" puller washer I made for an earlier project. It uses three puller bolts instead of two, but it's the same idea. By mounting the clamp on the bar at one end or the other, the S-Casting can be dragged in either direction just by tightening the puller bolts on the washers.

For this job, I'll make my own washers out of much thicker steel so I don't have to worry about them bending. The clamp and the casting should keep the washers from twisting or distorting. The spacing of the two Puller bolts will be set by the size of the casting.

Bedtime now.