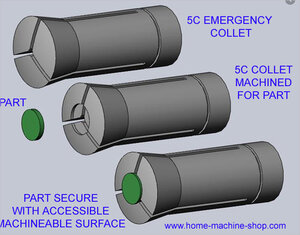

I don't have a 3D printer but I thought a good application might be a printed 5C collet to replicate what are sold as emergency collets. These are typically brass or machinable metal & quite spendy (hence I don't own any). Looks like someone else had the same idea. Although I'm not seeing the threads, maybe you need to make a donation for that LOL.

https://www.thingiverse.com/thing:3874554

https://www.thingiverse.com/thing:3874554