-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's Paul up to?

- Thread starter PaulL

- Start date

I've often wondered how people wound up with these kinds of things. Patience and being ready when the opportunity presents itself.That thing is a beast!

Looks like structural steel to me.I've often wondered how people wound up with these kinds of things. Patience and being ready when the opportunity presents itself.

140mower

Don

Unistrut......While I'm at it - anybody know what this stuff is called? Some form of modular warehouse stuff, I have an actual useful amount of it.

View attachment 34909

Good for you. Does it have a brother?This followed me home today:

I am looking at adding a steel top to my work bench, priced out a piece of plate .500x2'x6' the other day,,,,,,,$800 - ouch, that won't be happening any time soon.

Who did you call? I did better than that for the whole half-sheet delivered. (hardcore metals)Good for you. Does it have a brother?

I am looking at adding a steel top to my work bench, priced out a piece of plate .500x2'x6' the other day,,,,,,,$800 - ouch, that won't be happening any time soon.

Last spring, IIRC. Steel is pretty variable these days :-(That was Hardcore Metals. It works out to just about $3.00 a pound.

How long ago did you buy?

I paid $200 for my 3/8” 2’ x3’ from Island Waterjet including cutting to size.Good for you. Does it have a brother?

I am looking at adding a steel top to my work bench, priced out a piece of plate .500x2'x6' the other day,,,,,,,$800 - ouch, that won't be happening any time soon.

Is there a reason for the 1/2”?

I did 1/2" so I'd have decent holding in threaded holes. 3/8" would have been much more reasonable. Though I'm really happy with the sheer mass of the resulting bench.I paid $200 for my 3/8” 2’ x3’ from Island Waterjet including cutting to size.

Is there a reason for the 1/2”?

I went with 3x3 125 wall tubing for the legs for added mass. I clamped my brake to the to it yesterday to bend that stainless and it didn’t budge. Probably in the range of 160- 200 lbs all in.I did 1/2" so I'd have decent holding in threaded holes. 3/8" would have been much more reasonable. Though I'm really happy with the sheer mass of the resulting bench.

But mass is mass and a 1/2 top would be nice.

What Paul said, mass and the ability to drill and tap holes is a bonus, plus I could weld things to the table then grind them off when done.Is there a reason for the 1/2”?

I also called the place out by the airport.... darned if I can remember the name... United Steel maybe? They were slightly less than Island WaterJet but I didn't want plasma cut edges. The reason I went the way I did is they made the corners dead square. Very handy for fixturing up assemblies to the edge of the table for corners and 45's.What Paul said, mass and the ability to drill and tap holes is a bonus, plus I could weld things to the table then grind them off when done.

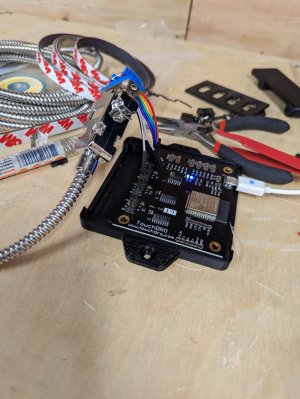

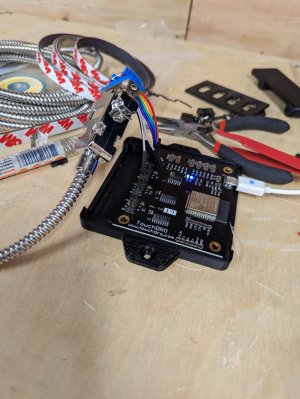

Delivery today.

[Edit:]

A bit of testing says that yes, the mill is getting the TouchDRO, and the lathe gets the HS800 currently on the mill. That will let me combine (or not) my quill Z and knee Z on the mill, and honestly, I do the fancier work there, so tthe TouchDRO interface will be better used there.

[Edit:]

A bit of testing says that yes, the mill is getting the TouchDRO, and the lathe gets the HS800 currently on the mill. That will let me combine (or not) my quill Z and knee Z on the mill, and honestly, I do the fancier work there, so tthe TouchDRO interface will be better used there.

Last edited:

This took much to long to do, but the DRO is now set up on the lathe. I used the "tape the scale to the machine" technique throughout, and was able to turn some scrap alumninium into a couple of brackets that bolt into the follow rest to hold the read heads. That annoying V notch is in the exact wrong place, though everything is quite firm how it's held now. And for the readout I have the old HS800 that I had on the mill until I installed the TouchDRO.

The last piece of the DRO adventure will be to get my knee scale in on the mill.

The last piece of the DRO adventure will be to get my knee scale in on the mill.

Any chance you'll rent that out? 🙂Added this orange boy to the shop today:

View attachment 35548

One hole in, I'm reasonably pleased. No negatives to write about yet. My steel-topped bench is gaining a section of 10cm grid, and my monster bench at the cabin will be getting holes to secure the bench shear and leg vise.

Give me a couple of weeks with the new toy, then we can talk ;-)Any chance you'll rent that out? 🙂