-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What size lathe do you have?

- Thread starter Susquatch

- Start date

Years ago I took the gap out so I could bore the centre out on a 24" steering wheel. I never put it back in, my carriage overhangs the end of the ways by 2 inches when I am tight to the chuck.

This would be ideal except......

I don't always have a regular chuck on my lathe. I quite often have one of the custom chucks I made for my lathe or a front spider on it. Sometimes I even use the MT5 taper without a chuck. Almost always, this is precision work so leaving the gap out or even replacing it without a full blown alignment simply wouldn't work for me.

Ya, my gap is NEVER coming out.

Smithy 1220XL clone from House of Tools (dating myself here). Igaging easy view DRO. About to convert to DC treadmill motor based on dazecars.com projects.

You are in good company with @mbond and a group of personal friends of mine who also have combo machines.

Currently I've got a Standard Modern 2000 series with 13" swing. Been a great machine, rebuilt it a few years back. Was a high-school machine that must have had an issue very early on with the electrics that they never bothered to fix, as the bed is almost perfect, but to motor was smoked.

Last edited:

So where in S Ontarrible are you?

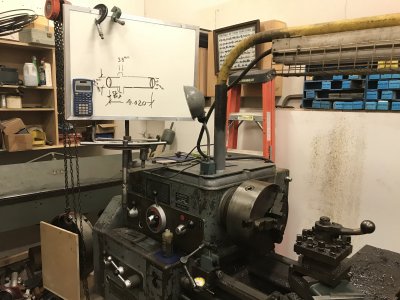

Have you seen the notifications about our April 6 meetup hosted by Modern Tool? Hope you can come. While at the meetup you’d be interested to have a look at the 6 used Standard Modern (14x40) lathes that Modern Tool just acquired from a northern college. They plan to demo one of them at the meetup. I’ll be getting more info on them and posting it soon on the Forum Here’s a pic

canadianhobbymetalworkers.com

canadianhobbymetalworkers.com

Have you seen the notifications about our April 6 meetup hosted by Modern Tool? Hope you can come. While at the meetup you’d be interested to have a look at the 6 used Standard Modern (14x40) lathes that Modern Tool just acquired from a northern college. They plan to demo one of them at the meetup. I’ll be getting more info on them and posting it soon on the Forum Here’s a pic

Ontario meetup, April 6

Meetup announcement for Southern Ontario (GTHA and The Golden Horseshoe) on Saturday April 6, 2024 at 10AM. MARCH 21st UPDATE. NOTICE - THE VENUE HAS CHANGED. PLEASE SEE THIS POST: Post in thread 'Ontario meetup, April 6'...

canadianhobbymetalworkers.com

canadianhobbymetalworkers.com

ChazzC

Ultra Member

Started out with an 8x20 (or maybe 8-1/2?) Taiwanese back in the 90's, but needed space so sold that and my Mill-Drill around 2003. Once I was able to reclaim the space, I got a MicroMark/Microlux 7/16, and have since added a number of "improvements." Would like to get a 10" Bench Lathe, but money is always a constraint.In an effort to understand our membership we ask everyone to complete the survey above as well as the other one about mills that will be posted shortly.

Yes, there is lots of other equipment and maybe they should be surveyed too but let's start with these two.

You may select as many options as appropriate and you can change your vote anytime.

I'm in the Niagara/Haldimand area. I will try and make it to the meet up, but quite honestly, I cant seem to plan anything more than 12 hours out without someone/something changing those plans without my consent....So where in S Ontarrible are you?

Nice lathe. What am I seeing on top of the nearest part of the ways, just in front of the tailstock? Is it way protection?Started with a Seneca Falls lathe. Moved up to an Atlas, to a Logan, but now have a Martin DLZ 502 20”x80”. I can change from imperial to metric threading with the flip of a lever. Has a taper attachment also

Martin

.View attachment 44866View attachment 44867

Martin w

Ultra Member

Hi Colin, thanks.Nice lathe. What am I seeing on top of the nearest part of the ways, just in front of the tailstock? Is it way protection?

yes they are aluminum flanges bolted to the carriage and way wipers. Keeps the chips away.

The one on the back, I had to tig weld back on. I was turning a 20-1/2” piece on my faceplate. I had clearance but not enough once I started taking a cut. It caught and broke it off..

Martin

Downwindtracker2

Ultra Member

A BusyBee DF1224g, 12x24,one of the belt drive generic Taiwanese. I haven't found out what machine shop DF is, so I'll just call it generic. I bought a Rong Fu 45 mill/drill and it for $1750. I valued the RF-45 at $1500. At the time new they were $5,500 USD. By my math I paid $250 . A fair bit more in the rebuild.

@Susquatch

I purchased a new Busy Bee Craftex CX708 on April 09, 2025 that is a 10" x 18". So far it seems to be good.

I choose this one as I was looking for a lathe that had:

1) a 1" pass through.

2) was a gearhead machine. Don't like equipment with electronic controls / control boards. I prefer simple equipment.

3) a 5" chuck as minium

4) cost and it was / is on sale for $600 off list price.

5) as heavy as possible within this class of machine. I figure the heavier the machine the better. According to their online spec sheet, online manual and the spec sheet that their floor model had attached to it the lathe supposedly weight in at 283kg ( 623.9 lbs ). Not

According to the labelling on the wooden crate it came in it has a N.W.: 120kg and G.W.: 140kg. That relates to a N.W. of 264.5 lbs. and a G.W. of 308.6 lbs. That is a far cry from the 623.9 lbs, as advertised. This was borne out when two old geezers and my son could lift it into place.

Just not happy with Busy Bee and their lack of response to my email outlining some minor and some major concerns.

I purchased a new Busy Bee Craftex CX708 on April 09, 2025 that is a 10" x 18". So far it seems to be good.

I choose this one as I was looking for a lathe that had:

1) a 1" pass through.

2) was a gearhead machine. Don't like equipment with electronic controls / control boards. I prefer simple equipment.

3) a 5" chuck as minium

4) cost and it was / is on sale for $600 off list price.

5) as heavy as possible within this class of machine. I figure the heavier the machine the better. According to their online spec sheet, online manual and the spec sheet that their floor model had attached to it the lathe supposedly weight in at 283kg ( 623.9 lbs ). Not

According to the labelling on the wooden crate it came in it has a N.W.: 120kg and G.W.: 140kg. That relates to a N.W. of 264.5 lbs. and a G.W. of 308.6 lbs. That is a far cry from the 623.9 lbs, as advertised. This was borne out when two old geezers and my son could lift it into place.

Just not happy with Busy Bee and their lack of response to my email outlining some minor and some major concerns.

Just not happy with Busy Bee and their lack of response to my email outlining some minor and some major concerns.

I'd say that is a majority opinion around here. There are quite a few members that like their Busy Bee Machines. But there are also lots of members who are not happy with Busy Bee Service or Support.

CX708/B2227L is the same as the BVB25 sold by a zillion Chinese suppliers. Realistic weight is 150 kgs, see https://ia601004.us.archive.org/34/items/lathe-manuals/BV20- BVB25 manuel.pdf for a weight chart for the various versions.

Busy Bee customer service is abysmal. Don’t expect a response. Takes BB months to respond to a request for a potential sale, my guess is complaints get filed in the oval file cabinet. If it’s worth fussing with, I’d be talking to the federal Competition Bureau, it’s illegal to advertise products with false claims.

However, I am very happy with my B2227L lathe, I’ve had it for about 15 years and it does what I want. My selection criteria was almost exactly the same as yours, only thing I would have liked is if it had a quick-change gear box for cutting threads.

Busy Bee customer service is abysmal. Don’t expect a response. Takes BB months to respond to a request for a potential sale, my guess is complaints get filed in the oval file cabinet. If it’s worth fussing with, I’d be talking to the federal Competition Bureau, it’s illegal to advertise products with false claims.

However, I am very happy with my B2227L lathe, I’ve had it for about 15 years and it does what I want. My selection criteria was almost exactly the same as yours, only thing I would have liked is if it had a quick-change gear box for cutting threads.

I hate being ignored by vendors but did put them on notice that if I don't hear back by Monday at noon I will be complaining to the government agencies. A simple email response or phone call would have probably been enough but now it is a matter of principal and maybe preventing some other person from maybe making a decision based on their specs.If it’s worth fussing with, I’d be talking to the federal Competition Bureau, it’s illegal to advertise products with false claims.

Thank you for the link even though it is in French it is a good resource.

Downwindtracker2

Ultra Member

My son and i went together on a lathe, a bare XIMA version of the common SEIG 10x22. I had completed it with parts from Lathemaster in Louisiana . When my son moved out, he took it with him. Sons do that. That was when I ended up getting the DF 12x24g. I had cause to use his to make a part when I had issues with my VFD. I had to redo the part. Boy did that ever give me impetus to fix my lathe. .