I'm in between phones right now (smashed mine) so cannot confirm his number.sounds interesting so how would one get in touch with him?

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sticky What Machines Do You have?

- Thread starter Jwest7788

- Start date

Tom O

Ultra Member

ok no problem I don't think there is anything in my forseeable future that I need. I'm thinking oxy act bottles may be my next purchase they can be used in casting sooting a shaft so it can be removed it is also used in casting babbit which I have plans to do on my steam engine crank.

Tom O

Ultra Member

If anyones interested here is a hand powered slotter on kijiji

http://www.kijiji.ca/v-tool-other/c...de/1089034280?enableSearchNavigationFlag=true

http://www.kijiji.ca/v-tool-other/c...de/1089034280?enableSearchNavigationFlag=true

Matt_b_m

Member

Just picked up a nice older lathe today off of Kijiji. Name is a TIDA-4A. Manufactured in 1979, as per the previous owner was used 2-3 times a year in 20 minute bursts over the last 15 years. Appears to be in great shape, came with hand fulls of tapers, tooling and the steady rest. Appears to be a gear set in the bottom of the box that came with it to convert it to cut metric threads, all of which in great condition.

Add this to the 80s Miller Thunderbolt AC/DC, 375 plasma and the Millermatic 135 mig.

No plans on projects as of yet, just getting my feat wet on this one! Looking forward to immersing myself in the self taught program!

Add this to the 80s Miller Thunderbolt AC/DC, 375 plasma and the Millermatic 135 mig.

No plans on projects as of yet, just getting my feat wet on this one! Looking forward to immersing myself in the self taught program!

Thats a good price, you'll always end up finding a project you want to go bigger for, and having stuff like gearheads are always nice, but having a machine in your basement when you need it just to bore something out around the house or when your fixing something is always nice!

Also, if (when) you are ready to sell that off and upgrade, the quick change gearbox makes it much, much more desirable and you could very well make a couple bucks on it as long as it doesnt have mechanical issues and you wait it out. I bought a southbend a couple years back for 1750 I believe, sold it about a year later for 2200.. if I had just taken the first offer I would have lost money but I wasn't in a hurry.

Also, if (when) you are ready to sell that off and upgrade, the quick change gearbox makes it much, much more desirable and you could very well make a couple bucks on it as long as it doesnt have mechanical issues and you wait it out. I bought a southbend a couple years back for 1750 I believe, sold it about a year later for 2200.. if I had just taken the first offer I would have lost money but I wasn't in a hurry.

Brian G

Member

I have just finished the evening class machining course at NAIT that is the Introduction to Machining. It was a great class where we learned to turn a diameter, bore a diameter, turn a taper, cut a groove, run 3 and 4 jaw chucks, run a dog-drive and sharpen drill bits by hand. The instructor is a Newfie that has been around the block and he was one of the best instructors I have ever had the pleasure of learning from. (and after 6 years of university that's quite a few)

Well worth the investment!!

After Christmas it's Threading 101 and then it's Milling 101.

Well worth the investment!!

After Christmas it's Threading 101 and then it's Milling 101.

Matt_b_m

Member

Glad to know my hunch on the price was accurate as a first time buyer of a lathe! I can almost guarantee it won't be that long before I find something I want to make that's too big.... Isn't that always the way it goes. It should serve me well, what I do is just stuff around the house for myself, for now...My shop is my detached garage at home... I somehow can see the wife ending up with a lot of precision handles on things around the kitchen just because I can! Haha

Not a problem at all kylemp, I paid what he was asking, $1500. I figured there would be quite an interest in something size and it fit in my shop well. Someday I might go bigger if the need arises.

That's a good deal Matt and it should be a good lathe also. The Taiwanese machines are a step up in quality from the mainland Chinese made ones.

sorrelcreek

Member

I have a modern 837 10x50 table milling machine that I have running on a phase converter because it's a 3 phase machine. I also have a modern 14x40 metal lathe that works great but going to be looking at buying another lathe that bigger because I've already had jobs that are to big for that lathe but I make it work. I do use the machines at my work for some stuff that is to big and doesn't take to much time. I have 3 different welders one is a lincoln sa 200 that I put in my truck when I have to go out and do some welding for people. Metal working is diffenitly more than a hobby for me and I'm interested in all metal related trades trying to learn as much as I can.

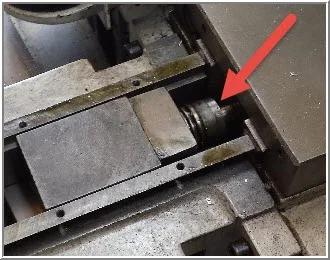

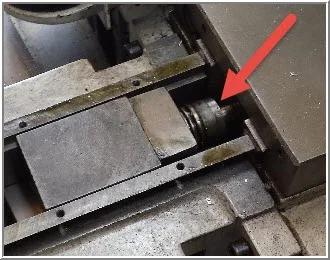

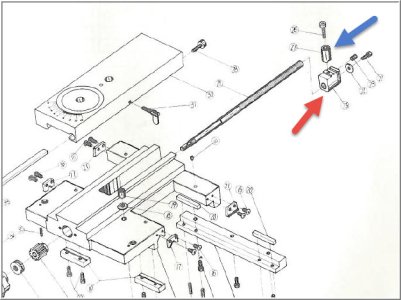

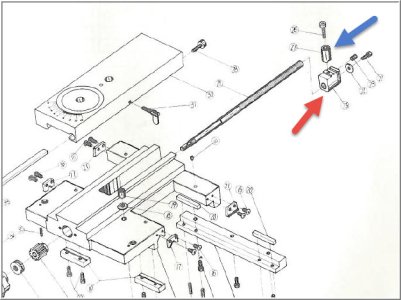

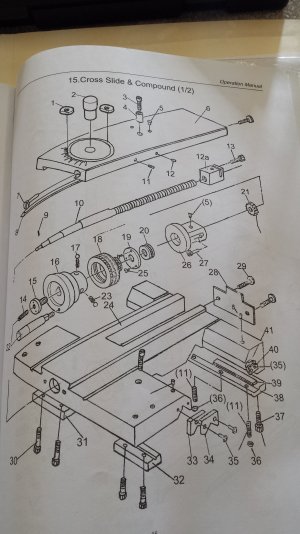

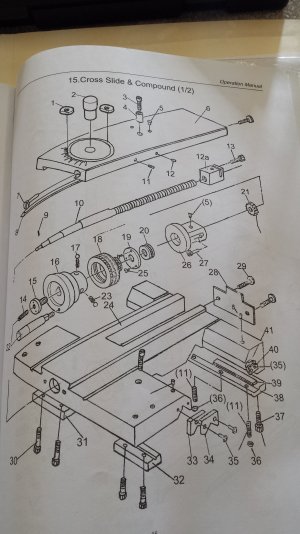

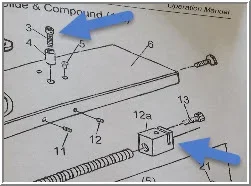

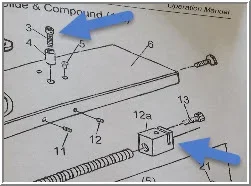

Sorrelcreek, I noticed what I think is a taper attachment on your 14x40? If so, do you happen to have a link to the parts manual or PDF by chance? I'm interested to see the assembly guts, how the y-axis lead screw is disengaged etc. By 'modern' do you mean a line that Modern Tools carried, or is that the brand name? Reason for asking is my (mid-90's) King 14x40 does not have taper attachment & I've been mulling over making something up. But I suspect it might be a more involved retrofit. I know some lathes have a special telescoping lead screw & disengagement assembly. But I thought I saw another offshore model that basically 'unhooked' the table from the lead screw nut so that it could free float for taper turning. Mine is kind of locked in place. Apparently taper attachment is kind of one of those big initial yes/no decisions you need to pick up front.

sorrelcreek

Member

Hi Peter

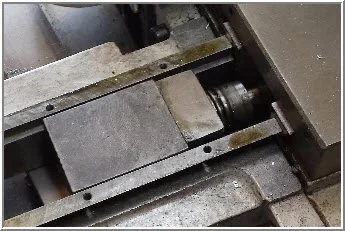

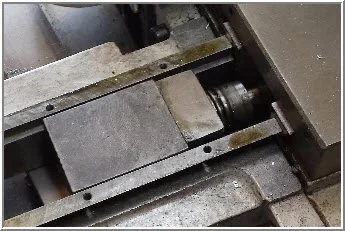

Yes the lathe is from modern tool and it had the taper attachment on it when I bight the lathe. Hopefully I can answer your questions so I don't have to take take a bolt or anything out of my cross feed the y axis to use the taper attachment. I don't have any drawing for the taper attachment it's self or a pdf it never came with any but I know you have to take the block off the back of the cross slide to put the taper attachment on and the lead screw does go inside another block I went out and took some photos of it for you. I haven't used it at all really just once to try it but my buddy bought the same mill and has set up his to re cut a mores taper and it worked good for him.

Yes the lathe is from modern tool and it had the taper attachment on it when I bight the lathe. Hopefully I can answer your questions so I don't have to take take a bolt or anything out of my cross feed the y axis to use the taper attachment. I don't have any drawing for the taper attachment it's self or a pdf it never came with any but I know you have to take the block off the back of the cross slide to put the taper attachment on and the lead screw does go inside another block I went out and took some photos of it for you. I haven't used it at all really just once to try it but my buddy bought the same mill and has set up his to re cut a mores taper and it worked good for him.

Thanks for taking the time to snap those pics, Ed. Very helpful. Hmm.. now that I see how things bolt up, very similar to my lathe. I'll have to check if I have those matching threaded holes. This is the part I've been wondering about - how the slider block attaches to the end of the lead screw. So dumb question, I can understand how the lead screw goes in the other block (taper attachment) but how do you 'disengage' lead screw from the main cross slide nut so the cross slide is able to float guided by taper slider assembly? ie. it looks like you have the same nut & bolt through the table as mine judging by the manual picture.

I think you have DRO on the Y-axis? Do you also have an X-axis scale? That's another potential issue I'll have to work around but looks like your taper brackets (holding the rod) just clamp on the bed way lip. Is that kind of how its installed?

I think you have DRO on the Y-axis? Do you also have an X-axis scale? That's another potential issue I'll have to work around but looks like your taper brackets (holding the rod) just clamp on the bed way lip. Is that kind of how its installed?

EricB

Active Member

@PeterT if I'm getting what you're asking right, this might help: the leadscrew won't really disengage, when you have your taper-attachment set up and you have the lathe feeding you can watch both hand-wheels move. The leadscrew is still driving the cross-slide back. When you want to disengage the taper attachment you just unbolt the attachment at the bottom of this photo with the two bolts and the taper-rod going into it so that it slides freely along the ways. Hope that helps.

sorrelcreek

Member

Yes Eric is right I don't unbolt any bolt on the cross slide but when you tighten the taper attachment clamp it moves the cross slide because if you actually unbolt your lead screw from you cross slide you won't be able to change your depth of cut. Now yes if you set your compound you can changed depth of cut but that's a different topic. Also yes I have a z axis readout and it's just bolted lower than the taper attachment so if you have one you just may need to lower it to clear the taper attachment. I'll take the bolt off and grab a picture for you of the block and everything that goes onto the lead screw.

Oh, duh me. I forgot you still have to have the lead screw engaged in order to alter depth of cut. Obviously I never understood how these things worked to begin with. So what am I missing here - if the taper attachment is now set up & its now 'connected' to the back end of the lead screw, does it actually draw the lead screw in & out on its own because its now constrained by the slider block? (by draw in & out I mean unscrewing the lead screw on its own). Is that the purpose of this rear connector part? If so, it must be some sort of bearing assembly? The end of my lead screw has cap screw & washer, assume that is removed & that's what the taper attachment part hooks on to?