From my experience of using carbide, even ground and polished ones, the DOC is only a small part of the story. For a polished carbide insert to not 'skate' as I call it, or

@little ol' e puts it 'grinds', you need pretty high RPMs and feed rates...

But for an ali-express insert or even a mid range Kinnemetal insert (which is all I have direct experience with), My minimum DOC is about 6-16 thou depending on the profile. If I hone it to a sharp insert I can get away with .004-008 minimum DOC. So for my purposes I never take less than .010 with a carbide insert, just to be safe.

So apart from making a theoretical discussion out of this, where's 'the meat'? For a non-ground cheaper coated carbide insert, you need to take at least the radius, if not more, which for the insets I buy is still a hefty chunk, around .010-.018 [correction]

For a ground an polished insert I take about .010 - no less certainly. I just have to plan my turning accordingly and leave enough for filing and honing as required.

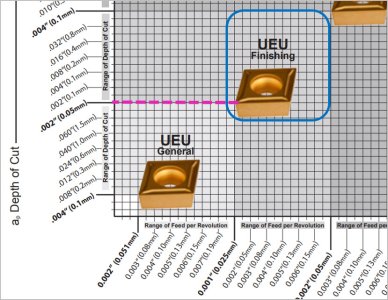

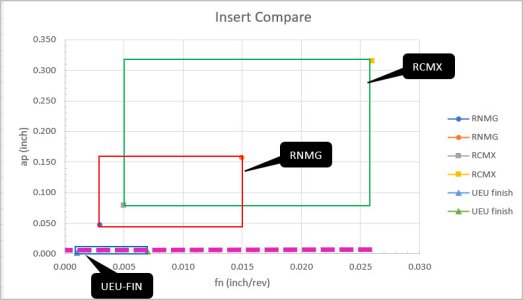

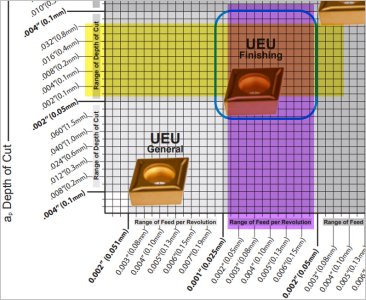

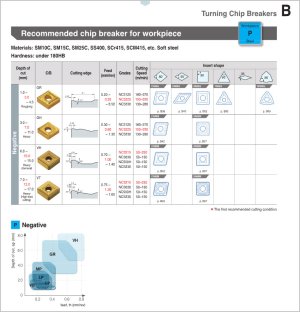

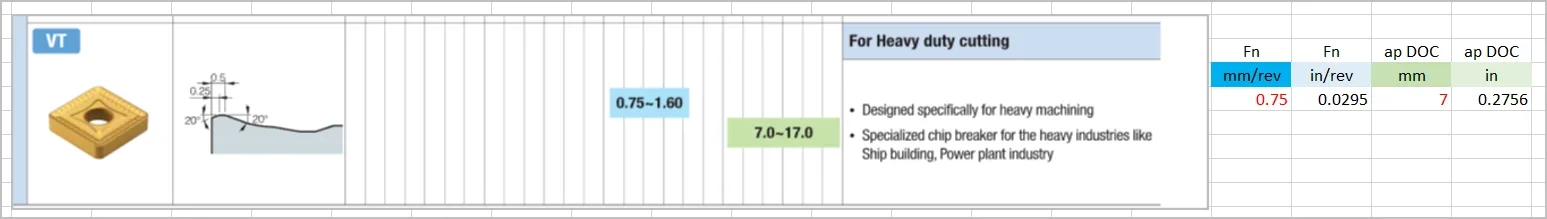

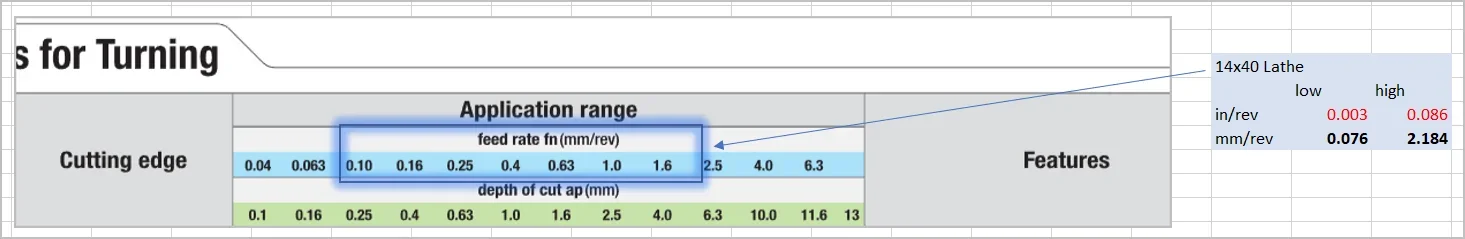

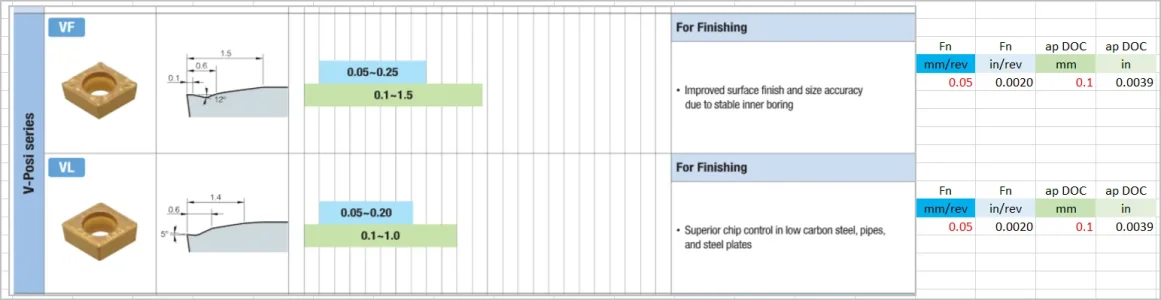

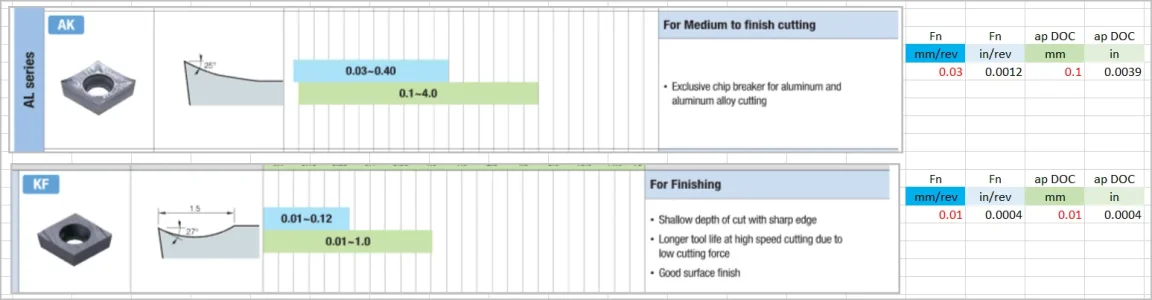

I will reference a different but well known manufacturer, Korloy. Their operating charts are a bit more straightforward to read. I'll do some metric to imperial conversions just for consistency (so check my math haha). These are off the shelf lathe inserts. I just pulled a few random ones that had the application 'finishing' in their description. I'm trying to direct attention to what the manufacturer recommends for feed (Fn) and depth of cut, DOC (ap) vs. the narrative discussion thus far, what people claim or have experienced as 'minimums'. Again, if I am out to lunch let me know. I'm just conveying what is in the specs.

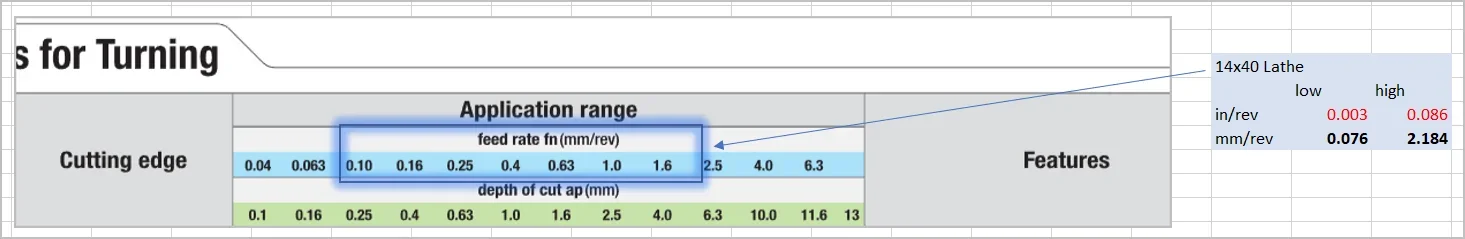

First off, I recall my 14x40 lathe has a power feed range of 0.003 - 0.086 inch/rev. That works out to .076 - 2.184 mm/rev so on Korloy application chart, roughly the blue box. That seems to be in a useable range of many carbide choices, just perusing the offerings. Some are outside the range as would be expected, so don't run those.

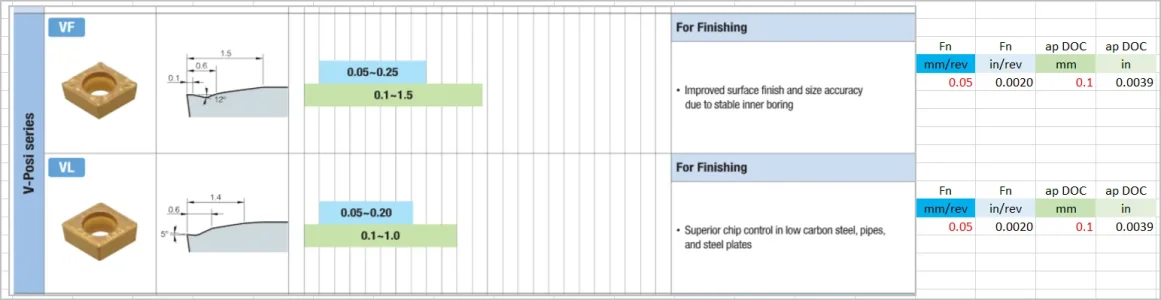

So here are some random finishers. Behind the scenes they vary by other sub-criteria - material suitability, coating, nose radius, rake geometry, chip control, blah-blah

I picked the low Fn & ap values off the respective blue/green bars & converted to imperial cells on right cells.

So in this example Fn=0.002 in/rev, DOC=0.004"

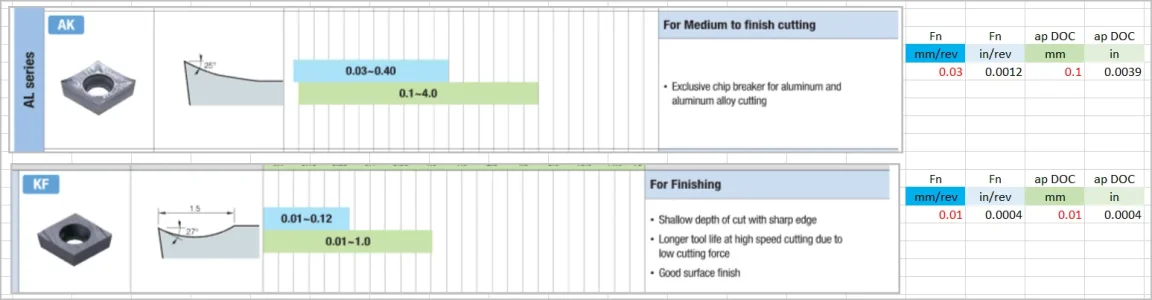

Some more. I actually use the AK myself for aluminum. It says DOC=0.004" but I can tell you (or show you next visit) a thou comes off as a tiny continuous thread. If I change feed & take off the hilltops I'm pretty sure its half that, 0.0005". On that basis, and I am only guessing here, I don't think the operating bars are hard stop do-not-pass limits. Obviously its peeling off a thou, just like you know your HSS is peeling off a thou. The bars (or operating windows on other vendors) is probably for guidance, or maybe extended tool life, or other factors important for manufacturing, I dunno. The point is, these DOC examples are not 10,20,30 thou just because its carbide.

Note the 2nd pic KF, insert. Min DOC = 0.0004" I have seen that style in Ali / Ebay lurkings. So I don't think they are super exotic or even 'new'. Now one could argue that Fn is very fine, outside the range of hobby lathe. But again will it be 'pretty good' at my min feed? I would wager a coffee yes.

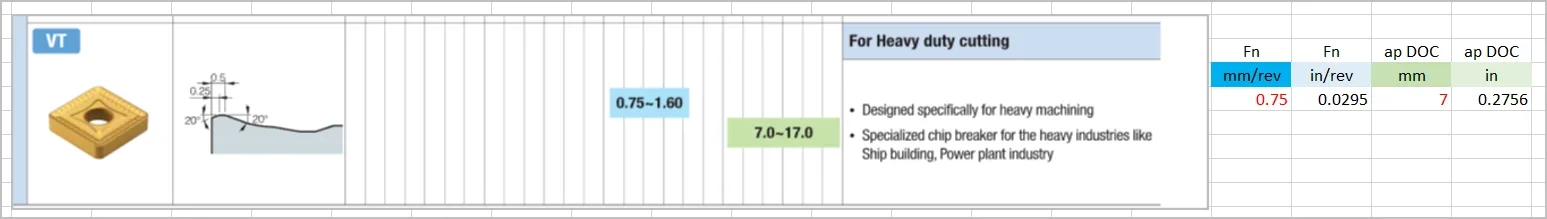

Example on the other end of the range, cited for heavy duty cutting. Minimum DOC of 0.275" That is a hefy bite. Very different cutting geometry as would be expected.

I hope you see where I'm going with this. On one end of the carbide spectrum are Finishers. On the other end are Roughers. In between is a bazillion other inserts. Which one do you have & what is the corresponding operating window?