-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tool Vevor Drill Bit Sharpener

- Thread starter canuck750

- Start date

Tool

TorontoBuilder

Sapientia et Doctrina Stabilitas

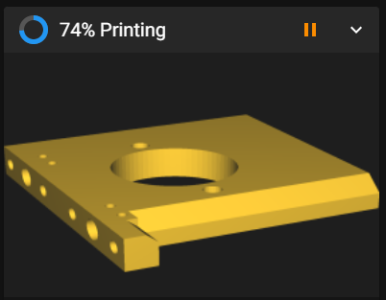

tool block B, yay

Last part, the tool block A is 25% done.tool block B, yay

TorontoBuilder

Sapientia et Doctrina Stabilitas

dont you mean duo motor mount?Last part, the tool block A is 25% done.

TorontoBuilder

Sapientia et Doctrina Stabilitas

Just to support the motor weight for the test, I have need to make a cradle support for the opposite end. That may allow the use of all plastic parts too.

TorontoBuilder

Sapientia et Doctrina Stabilitas

Okay I spent a few hours trying to get this motor and grinding wheel order completed and paid for. In the end I got it done and a little bit of a surprise.I'm losing track where I posted the wheel and motor order information...

I think it was this thread.

So update, the price of the wheels with shipping is $35.50 USD ($51 CAD) each. I'd hoped they'd give us a better deal on per wheel cost, but the shipping cost increase for all the wheels is only $5USD, so this is still a good deal indeed and 8 bucks cheaper per wheel than the lowest price I've ever seen these grinding wheels. The company with the lowest price per wheel wanted over 90 bucks for shipping.

The motors with shipping are $40 USD (57.35 CAD)

I dont know if we will get dinged for hst or not.

Alibaba charged a $24 CAD payment service fee, and their dollar conversion from USD to CAD was slightly different than when I checked.

Additionally hst hasn't been prepaid on this order so expect to have to pay that.

The cost for each wheel worked out to $52.97 CAD while the motors worked out to $59.68

TorontoBuilder

Sapientia et Doctrina Stabilitas

He's gotta come to me. 😀so you going to @YotaBota's tomorrow, or tonight? 😛

TorontoBuilder

Sapientia et Doctrina Stabilitas

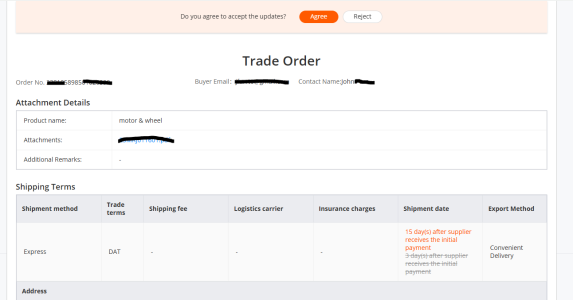

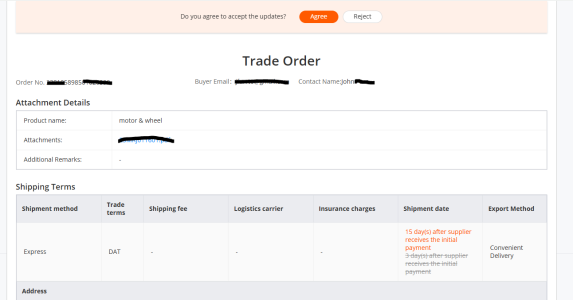

Okay so this is effing perturbing...

after I placed the order and paid the vendor modified the agreement. I can accept or reject the modification. They changed the fast shipping significantly and wont even ship the items for 15 days, and I dont know how long to arrive based on this.

Those people who agreed to order wheels/motors please advise what you think. I'll go with the majority. It's over $800 on my credit card waiting for these guys to deliver.

Edit:

I agreed after all after speaking to the rep again, and was told it was a thing with the alibaba platform. We shall see

after I placed the order and paid the vendor modified the agreement. I can accept or reject the modification. They changed the fast shipping significantly and wont even ship the items for 15 days, and I dont know how long to arrive based on this.

Those people who agreed to order wheels/motors please advise what you think. I'll go with the majority. It's over $800 on my credit card waiting for these guys to deliver.

Edit:

I agreed after all after speaking to the rep again, and was told it was a thing with the alibaba platform. We shall see

Last edited:

I'm in no rush for my wheel. I can send you some money to cover my share.Okay so this is effing perturbing...

after I placed the order and paid the vendor modified the agreement. I can accept or reject the modification. They changed the fast shipping significantly and wont even ship the items for 15 days, and I dont know how long to arrive based on this.

Those people who agreed to order wheels/motors please advise what you think. I'll go with the majority. It's over $800 on my credit card waiting for these guys to deliver.

View attachment 57943

Edit:

I agreed after all after speaking to the rep again, and was told it was a thing with the alibaba platform. We shall see

Canadium

Ian

+1I'm in no rush for my wheel. I can send you some money to cover my share.

I'm in no rush for my wheel. I can send you some money to cover my share.

+1 for Susquatch.

@TorontoBuilder - For me, this is experimental development. It's an objective of its own. So I'm in it up to my ears.

Btw, If they screw you, they screw me. It's part of the deal as far as I'm concerned. Usually I'm on my own in this game. I'm just happy to be part of team anti-cone!

@DavidR8 - Are you around this morning? I've checked with the scheduling department and I'm free this morning.

It'll give a chance to check out the reno'd digs.

@TorontoBuilder - any tricks or watch out for's taking the machine apart?

It'll give a chance to check out the reno'd digs.

@TorontoBuilder - any tricks or watch out for's taking the machine apart?

I’m around, but have a series of meetings all morning.@DavidR8 - Are you around this morning? I've checked with the scheduling department and I'm free this morning.

It'll give a chance to check out the reno'd digs.

@TorontoBuilder - any tricks or watch out for's taking the machine apart?

Tomorrow would be better.

Last edited:

I sharpened up 4 #3 center drills, just the point which is 7/64" (2.8mm). I used my 1/4" collet, since that's the size of the #3 body. The alignment station is for setting the drill bit stick out, and to position the lips of the bit parallel with the flats of the collet chuck. Well, the lips of drill bit wouldn't index on the alignment shelf, too small. So I just used that station for stick out, and eyeballed the lips using a magnifier.

I put the bit into the chuck, snug enough that I could still rotate the bit in the collet, sticking out longer than necessary, aligned the lips visually with the flats, and slightly more clockwise (with the point facing you.) This because when you tighten the collet chuck it wants to rotate slightly. (You gun guys remember what it's like installing a scope with Weaver rings?)

Then push the collet chuck into position in the alignment station and the drill bit will move backwards to its proper stick out. Then inspect and tighten the chuck.

If you plan to change the bit angle, say from 118° to 135°, you need more of the bit to stick out so as the grinding wheel will clean up the whole facet of the bit, unless you want a split point, and that station will clean up the bits trailing edge.

I put the bit into the chuck, snug enough that I could still rotate the bit in the collet, sticking out longer than necessary, aligned the lips visually with the flats, and slightly more clockwise (with the point facing you.) This because when you tighten the collet chuck it wants to rotate slightly. (You gun guys remember what it's like installing a scope with Weaver rings?)

Then push the collet chuck into position in the alignment station and the drill bit will move backwards to its proper stick out. Then inspect and tighten the chuck.

If you plan to change the bit angle, say from 118° to 135°, you need more of the bit to stick out so as the grinding wheel will clean up the whole facet of the bit, unless you want a split point, and that station will clean up the bits trailing edge.

Attachments

I sharpened up 4 #3 center drills,

Do you think you could pick a more difficult drill task?

I am truly impressed!

Makes me think I could sharpen the pilot on my piloted drill set. I wrote that task off prematurely I think.

TorontoBuilder

Sapientia et Doctrina Stabilitas

@DavidR8 - Are you around this morning? I've checked with the scheduling department and I'm free this morning.

It'll give a chance to check out the reno'd digs.

@TorontoBuilder - any tricks or watch out for's taking the machine apart?

No trick to taking this apart, other than having needle nose pliers handy to disconnect the motor lead. It's annoyingly short wire if you leave the motor attached.