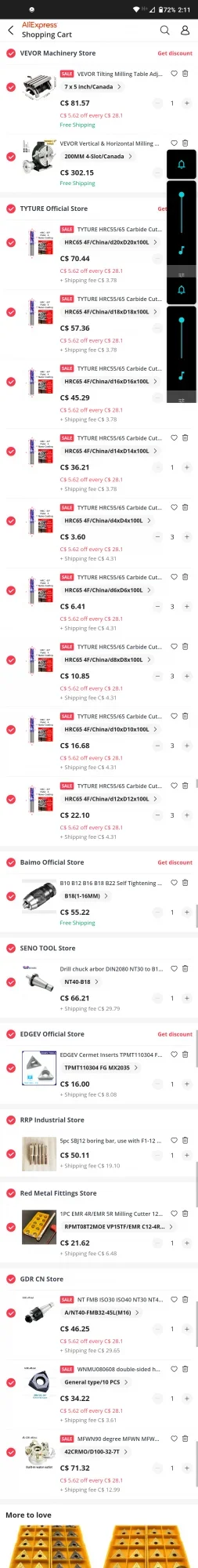

your missing 2 flute end mills, unless you only plan on working with steel, and you should buy multiples of the small-cheap endmills, namely the 8mm and under, sizes, anything 6mm and under explode pretty easily, and 8mm's are so cheap its worth having a few

it can (not always) take quite a while to get to you, so its worth stocking up, esp on the easy to break sizes/cheap sizes

it can (not always) take quite a while to get to you, so its worth stocking up, esp on the easy to break sizes/cheap sizes