I was thinking about that when I was using machine the other day but I would have upgrade my DRO computer thing as it only accepts 2 axis not sure how easy it is to mix and match dro scalesAdd a 3/4 axis DRO to your list.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tool Tooling up a milling machine

- Thread starter justin1

- Start date

Tool

I was thinking about that when I was using machine the other day but I would have upgrade my DRO computer thing as it only accepts 2 axis not sure how easy it is to mix and match dro scales

Ohh.... if you have a 2 axis DRO you're golden. An independent quill DRO can be added.

You're going to need tool holders i.e. Collets. What taper is your mill spindle?

Machinists squares come in handy as well.

My mills is a #40 taper and my draw bar is modified to used cat40 and iso40 I currently have 2 collet holders one being ER32 and other is oz25 I have a metric set of er32 and 1 - 3/4" oz collet that came with mill.Ohh.... if you have a 2 axis DRO you're golden. An independent quill DRO can be added.

You're going to need tool holders i.e. Collets. What taper is your mill spindle?

Machinists squares come in handy as well.

So I currently have 2 tool holders total both beeing collet holders and a homemade 3/4 shaft boring head adapter for my kms boring head

Watch the adverts on the Practical Machinist website, ISO and Cat stuff both move pretty fast.My mills is a #40 taper and my draw bar is modified to used cat40 and iso40 I currently have 2 collet holders one being ER32 and other is oz25 I have a metric set of er32 and 1 - 3/4" oz collet that came with mill.

So I currently have 2 tool holders total both beeing collet holders and a homemade 3/4 shaft boring head adapter for my kms boring head

I would suggest finding some relatively cheap, longer, small diameter collet holders, (ER-20, or smaller) on the logic that the length is not going to reduce the rigidity on, say, sub-3/8 inch mill cutters. And that is about the tipping point where, when you start buying above that size, the price of the cutter jumps a fair bit, due to the basic math of the cost of the amount of carbide rod needed. Not having to crook your neck to see down under a larger size nut can be pretty handy.

My advice is (Presented in the approximate order I'd acquire them if starting from scratch),

- get a good quality vise , drill chuck and collets (just saw the 40 taper, I'd focus one one ER collet holder/set and then end mill holders, you can work a 40 more than an R8 so end mill holders become more important) That'll cover 98% of it.

- Parallels, cheap are ok, its milling not grinding and if they're within a thou its good enough imo.

- Strap clamps, cheap is ok.

- Cheap square and hex 5c collet blocks. Super handy and low cost! (makes the most sense if you have good 5C collets for a lathe)

- Rotary table: buy a quality brand used. CNC has rendered them about obsolete in many commercial shops so there are usually some kicking about. Go the largest diameter you can (or can lift), 12" is my preference....else there is never enough room to mount things.

- Next, one shot oiler. Cheap oiler with good meters. Let stop wear before it starts!

- Angle plates of various sizes. Keep an eye out for a large ones, they come up used and are expensive new. V blocks. Cheap is likely ok for each, I prefer better stuff bought used.

- dividing head. Some RTs can be mounted vertically, but imo if you get a big enough RT, you can end up with clearance issues. I think DH bearing arrangements are better suited to the job job than an RT in the vertical position and they can also be tilted. Use quality would be my preference.

- Start collecting endmill holders. End mills pull out of collets in more extreme situations. Wrecked a part just two weeks ago...1/2" em @3000 pulled out. Grrrr....stupid me, I know better.

- A DRO is last on my list, (and many would argue with me on that placement). My rational is they are super convenient but doesn't really create new capabilities. Well, accuracy over a distance is one, but that is a) rarely needed and b) can be done other ways. Don't get me wrong, I love my DRO, but imo it makes sense to first acquire stuff that increases capabilities. IF you were buying everything all once, the yes, a DRO would be on my list.

- get a good quality vise , drill chuck and collets (just saw the 40 taper, I'd focus one one ER collet holder/set and then end mill holders, you can work a 40 more than an R8 so end mill holders become more important) That'll cover 98% of it.

- Parallels, cheap are ok, its milling not grinding and if they're within a thou its good enough imo.

- Strap clamps, cheap is ok.

- Cheap square and hex 5c collet blocks. Super handy and low cost! (makes the most sense if you have good 5C collets for a lathe)

- Rotary table: buy a quality brand used. CNC has rendered them about obsolete in many commercial shops so there are usually some kicking about. Go the largest diameter you can (or can lift), 12" is my preference....else there is never enough room to mount things.

- Next, one shot oiler. Cheap oiler with good meters. Let stop wear before it starts!

- Angle plates of various sizes. Keep an eye out for a large ones, they come up used and are expensive new. V blocks. Cheap is likely ok for each, I prefer better stuff bought used.

- dividing head. Some RTs can be mounted vertically, but imo if you get a big enough RT, you can end up with clearance issues. I think DH bearing arrangements are better suited to the job job than an RT in the vertical position and they can also be tilted. Use quality would be my preference.

- Start collecting endmill holders. End mills pull out of collets in more extreme situations. Wrecked a part just two weeks ago...1/2" em @3000 pulled out. Grrrr....stupid me, I know better.

- A DRO is last on my list, (and many would argue with me on that placement). My rational is they are super convenient but doesn't really create new capabilities. Well, accuracy over a distance is one, but that is a) rarely needed and b) can be done other ways. Don't get me wrong, I love my DRO, but imo it makes sense to first acquire stuff that increases capabilities. IF you were buying everything all once, the yes, a DRO would be on my list.

Last edited:

Make sure the t-nuts of the clamping set are sized for your table slots.

Get a keyless chuck with an integral straight shank, so that you can quickly attach to your collet chuck. I have a #40NMTB as well, and an E40 collet chuck is attached 90% of the time. I also have an ER11 collet chuck with 5/8" straight shank, so that I can chuck that in the ER40 when I need to use small endmills, or need clearance. My drill chuck is also 5/8" shank, so again, quick tool changes. And if you plan on getting fly cutters, get them with the same shank size, (though this is for lighter use. Heavy fly cuts should be held with endmill holders with the Weldon feature).

ER collets come in metric and imperial. Though they do overlap, it's better (more accurate, and more secure) to use the appropriate system for the tooling you will use. I have both.

Get a keyless chuck with an integral straight shank, so that you can quickly attach to your collet chuck. I have a #40NMTB as well, and an E40 collet chuck is attached 90% of the time. I also have an ER11 collet chuck with 5/8" straight shank, so that I can chuck that in the ER40 when I need to use small endmills, or need clearance. My drill chuck is also 5/8" shank, so again, quick tool changes. And if you plan on getting fly cutters, get them with the same shank size, (though this is for lighter use. Heavy fly cuts should be held with endmill holders with the Weldon feature).

ER collets come in metric and imperial. Though they do overlap, it's better (more accurate, and more secure) to use the appropriate system for the tooling you will use. I have both.

slow-poke

Ultra Member

I recently picked up a used Kurt vise. I received some good advice on this forum Before I ordered. The bottom line from what I gathered is don't buy the MIC made in China vises even if they look the same as the made in Taiwan vises. Autowell was one of the desirable MIT brands. I was able to get a used eBay Kurt delivered for less than a new MIT so that's what I did. Be careful (ask before ordering) if the ad is ambiguous it seems that some house brands that were MIT recently shifted to MIC. Shipping costs from the US can be prohibitive, I was lucky and found the used Kurt with low cost shipping IIRC $30. I'm at the cottage today but when I get back home I will add the MIT brands that my sleuthing turned up that had favourable reviews. It seems that no one is happy with the MIC clones.

Will have to look into integral straight shank stuff Imagine it's not as good for larger diameter drill bits but not sure what would slip first the chuck or the collets.Make sure the t-nuts of the clamping set are sized for your table slots.

Get a keyless chuck with an integral straight shank, so that you can quickly attach to your collet chuck. I have a #40NMTB as well, and an E40 collet chuck is attached 90% of the time. I also have an ER11 collet chuck with 5/8" straight shank, so that I can chuck that in the ER40 when I need to use small endmills, or need clearance. My drill chuck is also 5/8" shank, so again, quick tool changes. And if you plan on getting fly cutters, get them with the same shank size, (though this is for lighter use. Heavy fly cuts should be held with endmill holders with the Weldon feature).

ER collets come in metric and imperial. Though they do overlap, it's better (more accurate, and more secure) to use the appropriate system for the tooling you will use. I have both.

@Mcgyver

What would be a good starting point for endmill holders like 1/4 3/8 1/2 and 5/8 somthing like that?

I was looking at a used Bridgeport 12" rotary table not that long ago but was few kms out of range and didn't offer shipping lol. I can probly live without a dividing head for a bit so I don't mind hunting down a used one of those

@slow-poke

Ye I've been looking around ebay there is a couple used Kurt's on there atm but look pretty beat up so not sure if it's worth getting a well used Kurt and maybe repairing or reground

Downwindtracker2

Ultra Member

Cigarette papers !! You can touch off with them . They are .001 . I have an old style Japanese Yusa ? vise, I put them under the part and keep swatting the part until it behaves . The problem with papers is they look at you funny when you buy them.

Even cheap Chinese tooling is expensive.

Even cheap Chinese tooling is expensive.

those, plus up to 1". imo you don't need holders for small sizes for securing the EM, but it'll make using the mill nicer (quick to swap tools) vs having to change ER collets in holder for different sizes. What I see quite a few do is have lots of ER collet holders, each with one collet so it in effect becomes an end-mill holder of that collets size....that works as well...but probably more expensive unless you find a hoard of them for $10 a holder (which does happen)

I have mixed feelings about using AliExpress - the price is good but that is where it ends. I just ordered several solid carbide EMs from them today - hopefully, in a couple of weeks I will smile about it.

Got my DRO from AliE - saved a few 100$ but was painful.

I've had some bad experiences with KIJIJI but did well getting a 5" Precision Matthews vise a couple of years ago and a few months ago I did really well getting a dividing head with a bunch of tooling.

So, as others said - get what you need and watch for deals. With this in mind - maybe get an OK vise and watch for a bargain Kurt.

Got my DRO from AliE - saved a few 100$ but was painful.

I've had some bad experiences with KIJIJI but did well getting a 5" Precision Matthews vise a couple of years ago and a few months ago I did really well getting a dividing head with a bunch of tooling.

So, as others said - get what you need and watch for deals. With this in mind - maybe get an OK vise and watch for a bargain Kurt.

For all my mills I obtained a 3/4 - 7/8 double end box wrench. For mills based on the BP using 1/2" hold downs, it will do almost every hex fastener and the nod, yaw and ram bolts. It is large enough to give a tap to the drawbar. (yes I have a couple of the hammer/wrench drawbar thingies, but this is just as good).

I've seen good some stuff pop up on marketplace and Kijiji I'm hoping to find a nice dividing head from there but I'm thinking of cheaping out on a rotary table and just buying a 4" or 6" one to get me by on some of my smaller projects as I have nothing big coming down the pipeline yet for rotary related needs just small stuff I want to put nice radiuses on lol.

I looked up those spindexers they look pretty useful for adding wrench flats in stuff and maybe light gear cutting but looks like I would need to buy extended collet holder to make use out of one.

I'm currently compiling a AliExpress order im gonna post on here to make sure I'm not buying anything too useless as not 100% sure on boring bar styles but looking at getting one with a round insert and some triangle inserts. Kinda like a roughing one and a finishing one so I don't have to do a lot of heavy honing to clean a bore up. As sunen stones can get pricey pretty quick if your chipping them up all the time.

As far as hand tools go I'm pretty well set up on that stuff I've collected some pretty good stuff over the years being a welder by trade lol. Got probly 8 dead blow and brass hammers running around and consumable wrench's coming out of the wingwang

I'm doing some digging into some.of the vise brands posted here and was gonna do some looking around Ontario see if there is anything good and cheap enough to ship this way.

I looked up those spindexers they look pretty useful for adding wrench flats in stuff and maybe light gear cutting but looks like I would need to buy extended collet holder to make use out of one.

I'm currently compiling a AliExpress order im gonna post on here to make sure I'm not buying anything too useless as not 100% sure on boring bar styles but looking at getting one with a round insert and some triangle inserts. Kinda like a roughing one and a finishing one so I don't have to do a lot of heavy honing to clean a bore up. As sunen stones can get pricey pretty quick if your chipping them up all the time.

As far as hand tools go I'm pretty well set up on that stuff I've collected some pretty good stuff over the years being a welder by trade lol. Got probly 8 dead blow and brass hammers running around and consumable wrench's coming out of the wingwang

I'm doing some digging into some.of the vise brands posted here and was gonna do some looking around Ontario see if there is anything good and cheap enough to ship this way.

TorontoBuilder

Sapientia et Doctrina Stabilitas

I've seen good some stuff pop up on marketplace and Kijiji I'm hoping to find a nice dividing head from there but I'm thinking of cheaping out on a rotary table and just buying a 4" or 6" one to get me by on some of my smaller projects as I have nothing big coming down the pipeline yet for rotary related needs just small stuff I want to put nice radiuses on lol.

I looked up those spindexers they look pretty useful for adding wrench flats in stuff and maybe light gear cutting but looks like I would need to buy extended collet holder to make use out of one.

I'm currently compiling a AliExpress order im gonna post on here to make sure I'm not buying anything too useless as not 100% sure on boring bar styles but looking at getting one with a round insert and some triangle inserts. Kinda like a roughing one and a finishing one so I don't have to do a lot of heavy honing to clean a bore up. As sunen stones can get pricey pretty quick if your chipping them up all the time.

As far as hand tools go I'm pretty well set up on that stuff I've collected some pretty good stuff over the years being a welder by trade lol. Got probly 8 dead blow and brass hammers running around and consumable wrench's coming out of the wingwang

I'm doing some digging into some.of the vise brands posted here and was gonna do some looking around Ontario see if there is anything good and cheap enough to ship this way.

You can get by with regular collets to start with a spindexer. They're cheap and free shipping for amazon prime members. Oxtool has some great upgrades to do to spindexer to make it much more useful with added indexing plates.

Or a rose index simple, easy hex and square. Someone here posted instructions to make one, and someone here will sell you one

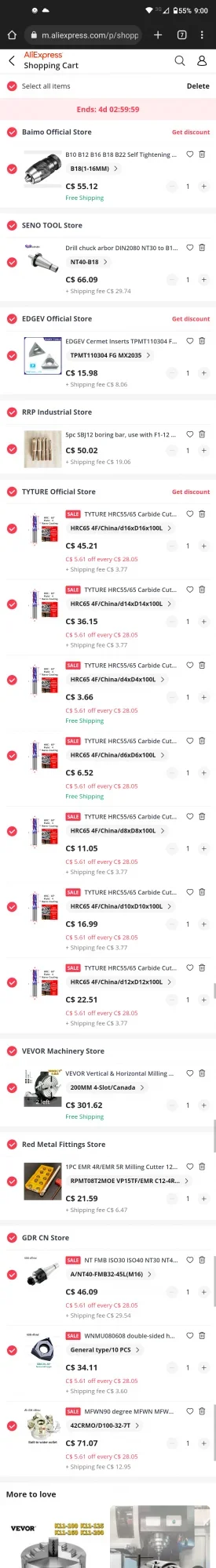

This is what I got so far in my ali cart probly gonna add few more things over the weekend before I order im gonna pick up some cheap parallels and 123s at kms tools next time I go into Kelowna lol. Gonna watch that oxtools video about the spindexer upgrade and see if it's something i think will be handy sooner then later but I'm thinking I can probly make do with just some collet blocks for now