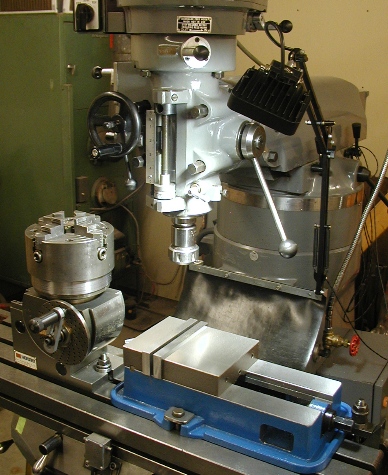

That's one thing that's still on my to do list, I have to make up a special tool though. If you didn't know, the Long Chang/First (& Sharp etc.) back lash adjuster/lock nut is not like a BP, you need the special tool to turn the adjuster sleeve and the ring lock nuts - see the lock nut image below.

Tool designed but not yet built.

Interesting to note that the leadscrews seem to be wearing very evenly (if at all?), probably because the nuts are part of the one-shot oiling circuit so they are regularly lubricated vs. what I have read about (some?) BPs that rely on splash/drip coming off of other parts (if I read correctly).

Making the adjustments is on the to do list but not at the top. The rest of the story? I got zinged a few days ago, my S.O. is a sharp one, she recently pointed out that I seem to be using the mill to make things to go with the mill and not other projects LOL! She encourages my play but sometimes those little zingers pop out!

At least I fixed the ice maker yesterday.

D