There is a fellow offering design services whom I'd ask to model something for me but it would violate US and CDN intellectual property laws. From what I understand I can copy the design for personal non-commercial use but others can't provide commercial services that relate to manufacturing designs covered by IP rights.

To model what I want requires lofting skills that are currently beyond me.

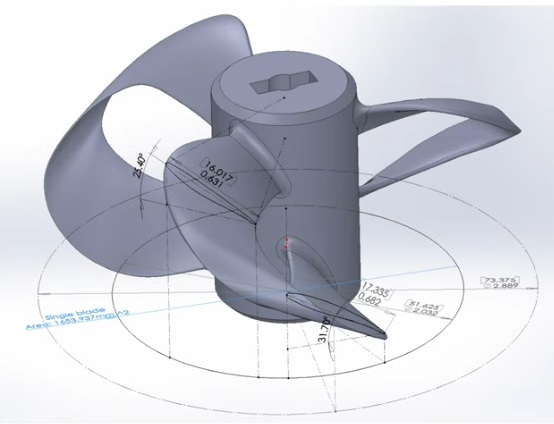

I don't know if anyone else has seen the marine propellers developed Sharrow marine, but they are revolutionary, and me being me, I just want to manufacture some to use on model boats and an electric drive for a kayak.

Now MIT's Lincoln lab has created and patented a similar type of propeller for aviation use, specifically in their case drones. They call them torroid props. There is a huge reduction in noise due to minimises tip vortices. Also greater efficiency by about 20% without any design work to optimize efficiency being done yet.

These new props are a wet dream for those who use micro drones for urban peeping. I think I can model these far simpler props but not the marine ones that I have been looking at the past few years

Here is the plant where they are making those interesting tipless props. It's a Titan CNC video. He is a little over the top but you gotta love his enthusiasm. How many $Million to build that place?