I have also thought you might be able to use either of the midpoints with a half rule to get you there too but I never tried it. Then again, maybe not..... I guess I should actually try that last one before I shoot my mouth off.......LOL!

yes - doing some math and calculation is all good but in the couple minutes it takes with the spindle square.........

OK, sometimes I am a sucker for punishment and way too curious about how things work and why they work that way. I just couldn't help myself. So I did some thinking.

There are a few observations that may be obvious to many and not so obvious to others.

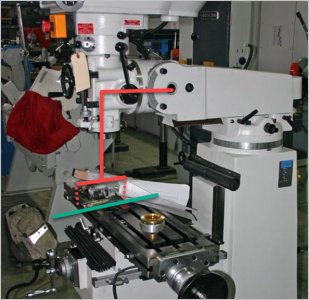

First off, I accept that the square tool is both fast and convenient. For those of us without one, the process isn't horrible though - just a lot more rigorous. Here are my thoughts on the matter.

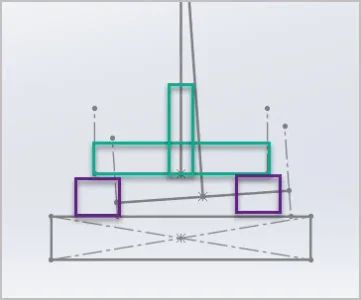

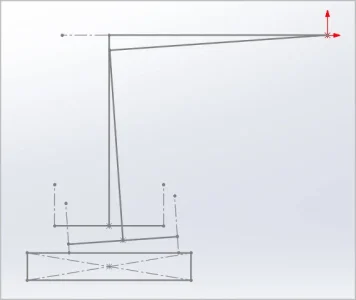

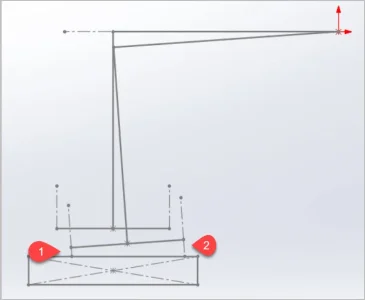

Unlike a regular clockwise / counterclockwise tram, a nod tram is not done on an axis that transects the bed. That's because the nod center of rotation is located quite a bit rear of the bed.

Therefore a standard split the difference approach to reaching tram square does not work. In fact, I was outright wrong to think it ever could.

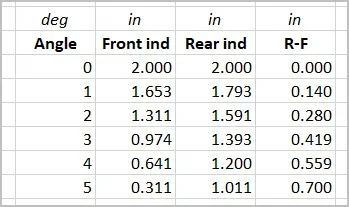

Basically, because the nod center of rotation is behind the bed, all the points that might be used on the bed to determine a tram condition all increase simultaneously as the head nods up or they all decrease simultaneously as the head nods down. However, the rate of increase or decrease changes in linear proportion to how far they are from the center of nod. The further they are forward toward the user, the faster they change.

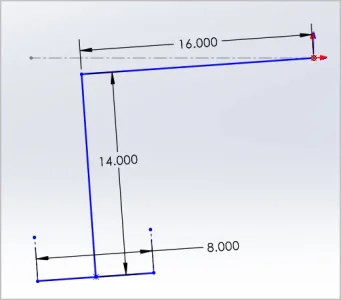

This last fact can also be used to advantage to improve tramming accuracy. I think everyone accepts that the longer the distance used to measure points on any plane, the better the obtainable accuracy. When tramming the nod, I think it is better to use the bed in the fully forward position EVEN if that means that the spindle is behind the bed. The reason for this is that moving the bed as far forward as possible, also increases the distance from the center of nod rotation to all the points that might be used and therefore increases the relative accuracy that can be achieved. For this assessment, I arbitrarily chose a point at the front of the bed and a point at the rear of the bed. As long as the head has already been trammed in the X-axis, neither one of the two nod reference points needs to be in line with the spindle. However, they do need to be somewhat consistent.

It will also be obvious to most others that adjusting nod should be done in the direction that tilts the head up. Just like moving a table or any other machining operation, backlash is best removed when working against the natural forces. In this case, gravity is trying to pull the head down, so it's best to operate the rack in the lifting direction in order to remove all the backlash while turning the nod pinion on the nod rack to change nod.

With these observations in hand, I set my mind to the business of how to tram the nod in a fast rigorous way instead of the trial and error method I have used myself and seen used elsewhere.

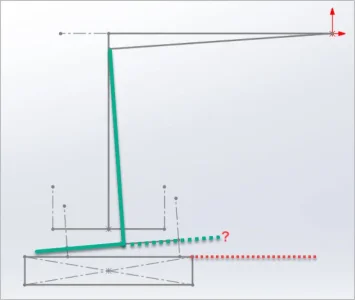

As noted above, its best to begin with the head down a bit from square. Then measure a position on the front and rear of the bed sequentially. If I began with the head nodded down a bit, the front bed position will be lower than the rear position. The head can then be lifted while measuring at the front by the entire difference between the two readings. This can be repeated until the difference is zero and then you are trammed.

The number of iterations can also be reduced by lifting the head by more than the difference. However as the difference gets small, this becomes more and more difficult to do.

If one is extremely careful, the number of iterations can be reduced to two by carefully limiting the extra adjustment to the ratio of the two point distances to the center of rotation of the nod times the difference.

However, overshooting square is easy to do, so I'm thinking that a somewhat more conservative approach is better. Besides, a few more iterations is a piece of cake if you are only swinging the indicator back and forth from the front to rear of the bed and back. Best of all, if the table is adjusted fully forward during this process, all the readings can be done without needing to go around to the other side of the mill to see the face of the indicator.

OK, so now I need to get off my butt and make a tram square......... LOL!

I might not make one that looks the same as a conventional one though. Mine will probably be triangular so I can keep the spindle behind the bed! Or does the improved accuracy really matter? Probably not for most operations. Maybe I'll make a conventional one too!