Amazing what is there.

I'll check it out. Thanks John.

Amazing what is there.

Merry Christmas! 🙂Well, I ordered the Bambu X1 Carbon with the AMS and some filament. Its getting shipped to my address on the other side of the border.

I'm guessing its probably best to stick with Bambu filament since its qr coded? or can I refill with cheaper stuff?

Hopefully you won't be restricted to one suppliers filament. That's like being told your MSM mill is ready to use but you can only use metal from Metal Supermarkets. The MSM mill won't function otherwise.Well, I ordered the Bambu X1 Carbon with the AMS and some filament. Its getting shipped to my address on the other side of the border.

I'm guessing its probably best to stick with Bambu filament since its qr coded? or can I refill with cheaper stuff?

Using generic filament is no problem. You can tweak all the settings for any particular filament in the AMS settings. All the usual problems with generic filaments apply such as somewhat random diameters and bad spooling. I had a bunch of filaments from 3D Printing Canada that were crosswound and wouldn't feed properly until I respooled them. They gave me credit for one or two but I was on my own for the rest. Beware of filament on cardboard spools as they can spread over time and then the crosswinding problem happens again. The Bambu filament also comes in rolls with no spools for a bit less. You just insert a 2 piece spool into the winding and you are good to go. The AMS is nice for super long prints or for using up the last few bits from different spools. It will just change to the next spool in the lineup as long as it is the same material. No regrets so far. The app will tell you if there is a problem with the print at anytime and it does an inspection of the first layer before proceeding. Fail fast, lather, rinse, repeat.Well, I ordered the Bambu X1 Carbon with the AMS and some filament. Its getting shipped to my address on the other side of the border.

I'm guessing its probably best to stick with Bambu filament since its qr coded? or can I refill with cheaper stuff?

Well, I ordered the Bambu X1 Carbon with the AMS and some filament. Its getting shipped to my address on the other side of the border.

I'm guessing its probably best to stick with Bambu filament since its qr coded? or can I refill with cheaper stuff?

I really hope I have the same experience with it as the many review videos I watched. Seems like a solid unit. Print speed and flexibility are really what got me. I watched one video where he had a lower end printer making a very simple part and it took 2.5 hours, and another video where a guy made a much more complex part on the X1 and it was done in 15 minutes, and the print quality difference was obvious.

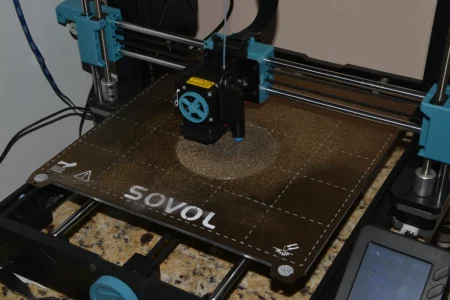

The Carbon X1 is in an enclosed cabinet. I keep mine in the shop and the shop stays around 12 to 15C. It prints just fine at that temperature. Not sure how it would be at freezing or colder. With the enclosed cabinet the heating of the bed warms the cabinet to some degree. I haven't noticed much of a smell when printing PLA or PETG. It connects to wifi, no need for a wired connection. While the printer should be kept fairly level, the leveling talked about refers to the relationship between the print head and the bed that the print sits on. The Carbon X1 does the bed leveling automatically at the start of every print by default. The Bambu Labs slicer program and the phone app both allow remote viewing of the printing progress and the app will notify you if things go wrong. The printer has a built in camera so no need to hook one up to monitor things.Then there are the REALLY LUCKY GUYS like me who get to watch your nooby swim and see if the gators get you before we tiptoe our way into the deep water too...... Please do keep us posted Darren. And please spare us no details.

Some quick questions for the swim team:

Can this thing be put in the shop and run off WiFi or does it have to be next to a computer?

I keep my barn just above freezing for the winter. Is the printer temperature sensitive? Would I have to keep the barn warm all winter or could i just turn up the temperature out in the barn each time I use it, or will it work fine when its cold?

I've heard they have to be levelled. Does that rule out a rolling cart? Or can I place the cart, level the printer, and then press go?

My wife has an amazing nose. If I get I could get her to do it, she could track rabbits like a beagle. Do these things stink when they print? Are some wires more stinky than others?

PLA is a plastic made out of plants. I kind of smells sweet when printing. If you buy one, you could have it in the house unless you want to print exotics like ABS. Leveling is within the machine. It needs a stable platform or table to sit on as there is fast movement within that can cause vibration if not on a solid surface..Then there are the REALLY LUCKY GUYS like me who get to watch your nooby swim and see if the gators get you before we tiptoe our way into the deep water too...... Please do keep us posted Darren. And please spare us no details.

Some quick questions for the swim team:

Can this thing be put in the shop and run off WiFi or does it have to be next to a computer?

I keep my barn just above freezing for the winter. Is the printer temperature sensitive? Would I have to keep the barn warm all winter or could i just turn up the temperature out in the barn each time I use it, or will it work fine when its cold?

I've heard they have to be levelled. Does that rule out a rolling cart? Or can I place the cart, level the printer, and then press go?

My wife has an amazing nose. If I get I could get her to do it, she could track rabbits like a beagle. Do these things stink when they print? Are some wires more stinky than others?