Truth be told I am in awe at all of you who are fluent in all things electronic. I would love to develop my knowledge in this area so that I have a better understanding of what I'm working with and how it works.For now...... 😉

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tool Soldering iron recommendation

- Thread starter David

- Start date

Tool

slow-poke

Ultra Member

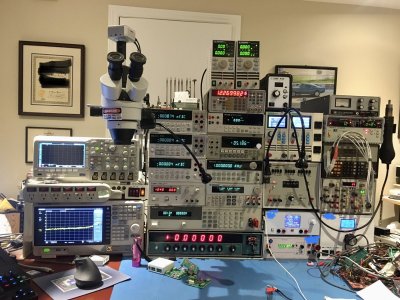

Be careful it's a slippery slope, on one of the electronic forums I visit one of the popular threads is the TEA thread, Test Equipment Anonymous(TEA) group therapy.I'm sure it won't surprise you to know that this will be the most advance piece of electronics related gear I own 😀

Common diagnosis is for GAS Gear Acquisition Syndrome.

Fortunately I have a mild case, some have it pretty bad.

Last edited:

Fortunately I have a mild case, some have it pretty bad.

Is that all yours? Holy CRAP! Some really cool stuff there. Especially that POJ Analog Randomizer in the bottom right corner. I have several of those. Incredibly useful.

Begs the question: What do you do with all that?

Dan Dubeau

Ultra Member

That's the same way I feel, and what got me started playing around with electronics again a few years ago. Get a few project kits from banggood/ali to practice with, and end up with something cool like the oscope one. I still don't really "know" what I'm doing, but I know a lot more than when I started 😀Truth be told I am in awe at all of you who are fluent in all things electronic. I would love to develop my knowledge in this area so that I have a better understanding of what I'm working with and how it works.

You'll love having a bench station vs iron. Now if I could just find time to clean off my bench and work through all the electronic projects sitting around I'd be set lol.

slow-poke

Ultra Member

I sold a lot more than I still have, and trust me I have plenty of POJ analog randomizers ;-)Is that all yours? Holy CRAP! Some really cool stuff there. Especially that POJ Analog Randomizer in the bottom right corner. I have several of those. Incredibly useful.

Begs the question: What do you do with all that?

I'm retired now but spent most of my career designing electronics from the 70's on. Later part I helped companies commercialize their half baked or non-compliant equipment. I kept some basic gear because I continue to do the odd hobby project or respond to a few old but good clients. One of them from Texas still sends me a turkey every thanksgiving.

you win.Be careful it's a slippery slope, on one of the electronic forums I visit one of the popular threads is the TEA thread, Test Equipment Anonymous(TEA) group therapy.

Common diagnosis is for GAS Gear Acquisition Syndrome.

Fortunately I have a mild case, some have it pretty bad.

View attachment 32123

Canadium

Ian

What is your favorite source for replacement tips on the Metcal? I have one (SP200) I acquired at an auction ages ago but its missing the tip. Was always meaning to get one but my Hakko was my standby so never got around to it.I'm spoiled I have a couple of Metcal however I would not recommend them for your use because they are not very portable and are overkill for your purpose. BTW they heat up in 3-4 seconds!

I have not used Hako but from what I have read a lot of people like them.

I'm closer to the back of the pack, check out these contenders from the TEA group.

I think that's a bit hilarious to be honest. That's a bit like one guy owning 23 mills and 17 lathes with no tooling.

Last edited:

I'm retired now but spent most of my career designing electronics from the 70's on.

A large part of my career was the same. My job for many years was converting automotive electromechanical systems to electronics and digital systems. At first all my really good tools belonged to the company. But as good equipment became available on the used market, I started to build my personal capabilities. Just like machining, I also built some of it myself. Virtually nothing I have today was purchased new.

I had no real "clients" except for the corporation I worked for until I retired. Today, everything I do is for others, for the farm, or for the fun of it.

slow-poke

Ultra Member

I have never used the SP200 it's smaller and lower frequency than the MX-500's I use.What is your favorite source for replacement tips on the Metcal? I have one (SP200) I acquired at an auction ages ago but its missing the tip. Was always meaning to get one but my Hakko was my standby so never got around to it.

I purchased both Metcals used on eBay and one of them came with about 10 tips, since then I picked up a couple of tips at Digi-Key. The Thermaltronics tips are compatible.

Go to tips for 90% of what I do:

STTC-145 for most small PCB related

SMTC-0147 for larger connections

My hunch is after you use it once, you will never want to use your old iron again. The technology is just that much better.

It's like using a Starrett 91B vs. a dollar store tap handle, it just works better in every way.

Last edited:

slow-poke

Ultra Member

I agree. That being said I think there are some parallels to machine tools WRT quality and serviceability of some of this older equipment compared to the new equipment. The ability to source some of this kit (especially when it needs repair) for pennies on the dollar also has some appeal. Almost everything in my picture was purchased as for repair or not working. Good quality old DMM's actually drift less than brand new versions of the same with the same references because they have had years to stabilize, just like a seasoned engine block is more stable than a brand new one. I just keep what I continue to use and sell off what I don't to keep the stack in check. I have found some people go on an on about how great a particular piece of equipment is and then I get one, fix it and find it's okay but lacking compared to some other similar piece of equipment, so it gets sold. When I can't reach it from my chair, the stack is too large and needs to be purged.I think that's a bit hilarious to be honest. That's a bit like one guy owning 23 mills and 17 lathes with no tooling.

I never worked professional on anything mass production automotive related, I think I would have enjoyed that. Seems like it could be quite challenging from the mass production perspective. If something gets missed during evaluation, not so easy to fix when there being pumped out like jelly beans. I mostly worked on lower volume quite expensive systems. Did do some higher volume smart meter design for power utility metering.

Last edited:

Scopes on bang sticks, yes 😉Everyone needs a scope right 😎

Scopes on bang sticks, yes 😉

well ya that to! PEW! PEW!

I’m going to have to go back and re-read this thread. The Weller gun is my go-to, the blue point is when I need more heat.

I’m going to have to go back and re-read this thread. The Weller gun is my go-to, the blue point is when I need more heat.I’m commonly soldering 14-20 gauge wires, if it’s bigger than than I’ll usually just use a butane torch.

I haven’t had any luck with the pencil style torches, for what I do, they don’t seem to have enough heat

I’m pretty sure I’m using lead solder, rosin core. I don’t know anything about lead free solder, hadn’t even heard of it until this thread

I’m going to have to go back and re-read this thread. The Weller gun is my go-to, the blue point is when I need more heat.

I’m commonly soldering 14-20 gauge wires, if it’s bigger than than I’ll usually just use a butane torch.

I haven’t had any luck with the pencil style torches, for what I do, they don’t seem to have enough heat

No worries @Chickenlights.

Your gun is is just fine for electrical wires like you describe. And just as you have found, a pencil unit won't work well for that.

The pencil style units are for soldering transistors, resistors and integrated circuits. Your big gun generates too much heat too fast and would damage these delicate components.

On the other hand the small pencil units don't generate enough heat to properly solder big wires.

They each have their place. It's sorta like using a 3/4 inch ratchet on a #6 screw.

I’m pretty sure I’m using lead solder, rosin core. I don’t know anything about lead free solder, hadn’t even heard of it until this thread

Lead free solder has been around for a while. It mostly an environmental thing. Very common in electronics and requires a bit higher temperature. If you have lead solder it's ok to use it to join wires.

140mower

Don

Some mornings a bottle of scope comes in handy as well.......😳Scopes on bang sticks, yes 😉

Yep, horses for courses. After all this talk I tallied up my collection and I have 8 including a couple of those big Weller guns, a variety of others good for soldering tanks on rads down to things for fine work on PC boards. I even have one of those WTCP stations like below that I picked up for peanuts about 30 years ago. Still going on strong thanks to the last (now obsolete) TC201T iron that Weller had in stock and gifted me when I asked for a warranty replacement for a defective out of the box thermostatic switch. Just used it to assemble the interface boards for my DROs.The pencil style units are for soldering transistors, resistors and integrated circuits. Your big gun generates too much heat too fast and would damage these delicate components.

Looks a lot better than @slow-poke 's link. 😉

12 PCS/Set Weller Tips Welding Iron Head Soldering Station Kit | eBay

Find many great new & used options and get the best deals for 12 PCS/Set Weller Tips Welding Iron Head Soldering Station Kit at the best online prices at eBay! Free shipping for many products!www.ebay.ca

D 😎