I’d probably go with just the gasket glue, very thin. On old machinery you can go to town on gaskets, but with precision fits it can interfere if too thick in my experience,

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

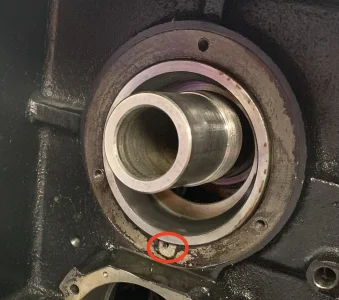

The reservoir seems to connect to both sides and there is this little hole the oil comes out and up through the bearing cover - that square slot and into the bearing. So the one sight glass covers the whole thing. That empty hole to the right you pointed out earlier Rudy is the drain cock. I guess it does not take much oil at all.Any conditions associated with the 24h cure time like temp, humidity, etc?

Question: how is the bearing oil retained if you have a “dry” HS? Is there a reservoir of sorts for each of them and individual sight glasses for observation of the level?

I was astounded. I certainly didn't spend that much!OMG that's pricey!

congrats on the reassembly - go John!

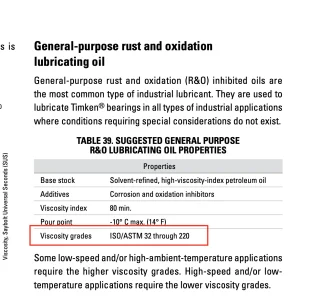

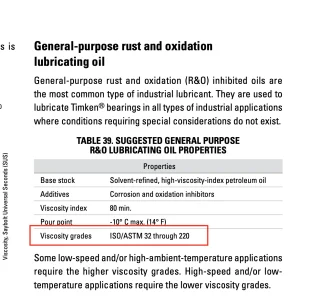

Timken bearing lubricant. What should I use? I found this pretty vague statement on the Timken site yesterday. ISO 32 through 220. That site is full of complex detailed information but specific advice is lacking. I have on hand iso 32 and 220. I'm sure any lubricant would suffice but what should I actually use? The timken site also equally vague on what preload should be used. Loads of technical information on various preload measurement techniques.. but how about an actual number like ft lbs?

RobinHood

Ultra Member

I’d use the ISO 32.

To seat the bearings, I would use a good amount of force (maybe 20-40 ftlbs) while turning the spindle. Back off the nut. Turn the spindle and snug up the nut. Use a pry bar with blocks of wood and an indicator to see if you get any end play (axially) and side play (radially). Adjust the nut to just eliminate play. This will probably leave the bearings a bit loose - that is ok to start with.

Run the lathe and monitor temperature. The bearings should get warm, but not hot. Adjust nut as required to give you the temp you want; about 45*C is what I set my spindle bearings to.

Once you have the bearings running at a steady temp, make some test cuts. If you get chatter (especially while parting), tighten up the pre-load a bit more. At this point you are moving the nut maybe 5* or 10* of arc - basically very little. Monitor and adjust as the bearings are “running in”.

To seat the bearings, I would use a good amount of force (maybe 20-40 ftlbs) while turning the spindle. Back off the nut. Turn the spindle and snug up the nut. Use a pry bar with blocks of wood and an indicator to see if you get any end play (axially) and side play (radially). Adjust the nut to just eliminate play. This will probably leave the bearings a bit loose - that is ok to start with.

Run the lathe and monitor temperature. The bearings should get warm, but not hot. Adjust nut as required to give you the temp you want; about 45*C is what I set my spindle bearings to.

Once you have the bearings running at a steady temp, make some test cuts. If you get chatter (especially while parting), tighten up the pre-load a bit more. At this point you are moving the nut maybe 5* or 10* of arc - basically very little. Monitor and adjust as the bearings are “running in”.

While still a reasonably pricy lathe, in 2000 the Australian dollar was as low as about $0.50 USD.OMG that's pricey!

congrats on the reassembly - go John!

Dave

I'd also echo the ISO 32 for the Timken, and if it were plain bearings (babbit) I go with the 220.

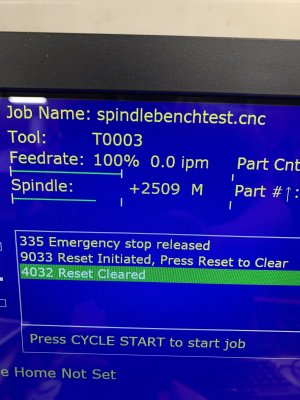

Lathe running for an hour. 30C. 2500 rpm. I’m pretty happy with that. Thanks for advice and calls John Rudy Kevin.