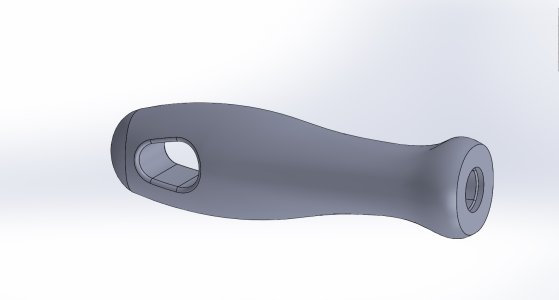

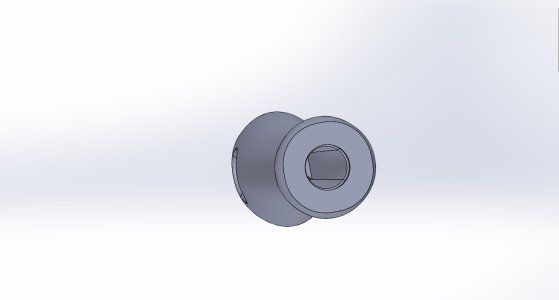

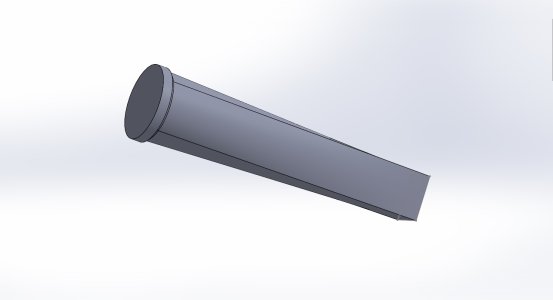

No. Went down a different rabbit hole and the ladder is missing again. Had a bad cold and when i stood up liquid would pour out my nose. So leaking over the shop stuff was a no go. Given the low melting temperature of PLA I suspect the tang on the file can be heated without destroying the file temper. A quick insertion into the insert and likely it would melt in place and stay there.John, did you go any farther with this? It's the weekend and I might play with it a bit

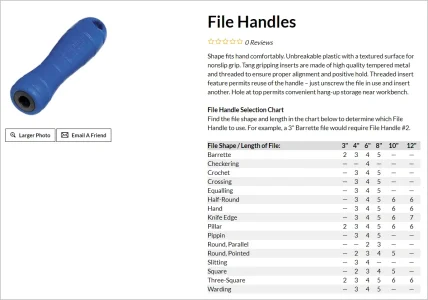

At the moment I have a few extra file handles a inherited from my son's toolbox but this is project #42.