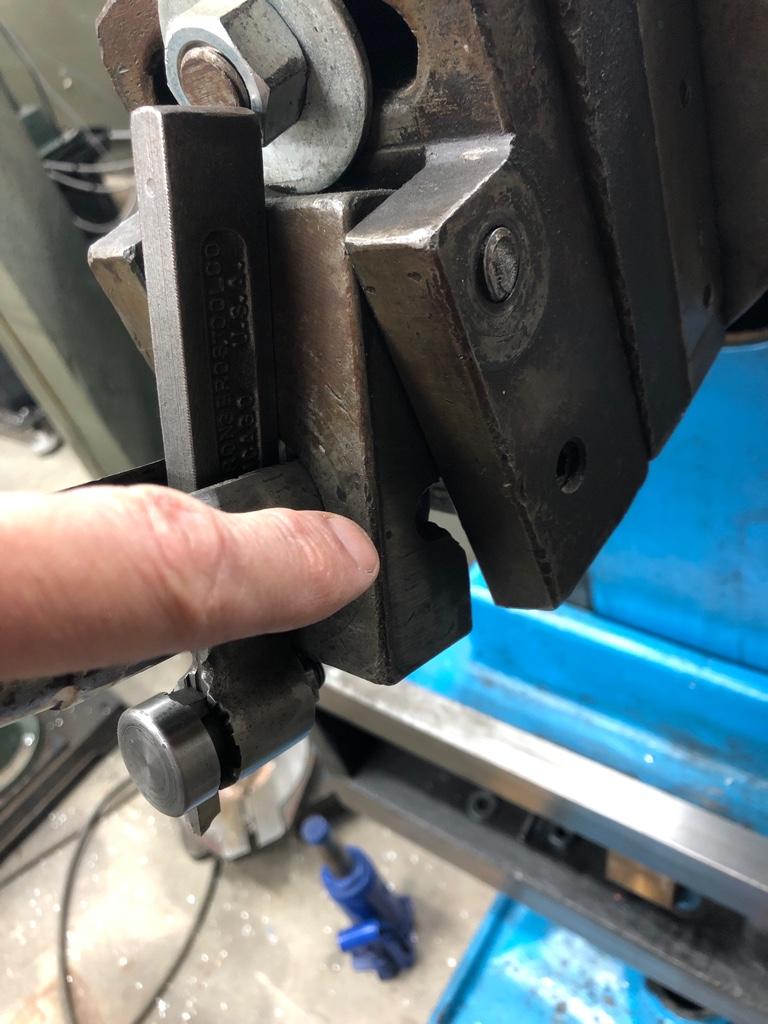

Some pics from the southbend, I have replaced the clapper box

Here is the clapper

And on the big shaper, the boring bars I got with it were all homemade, and welded solid

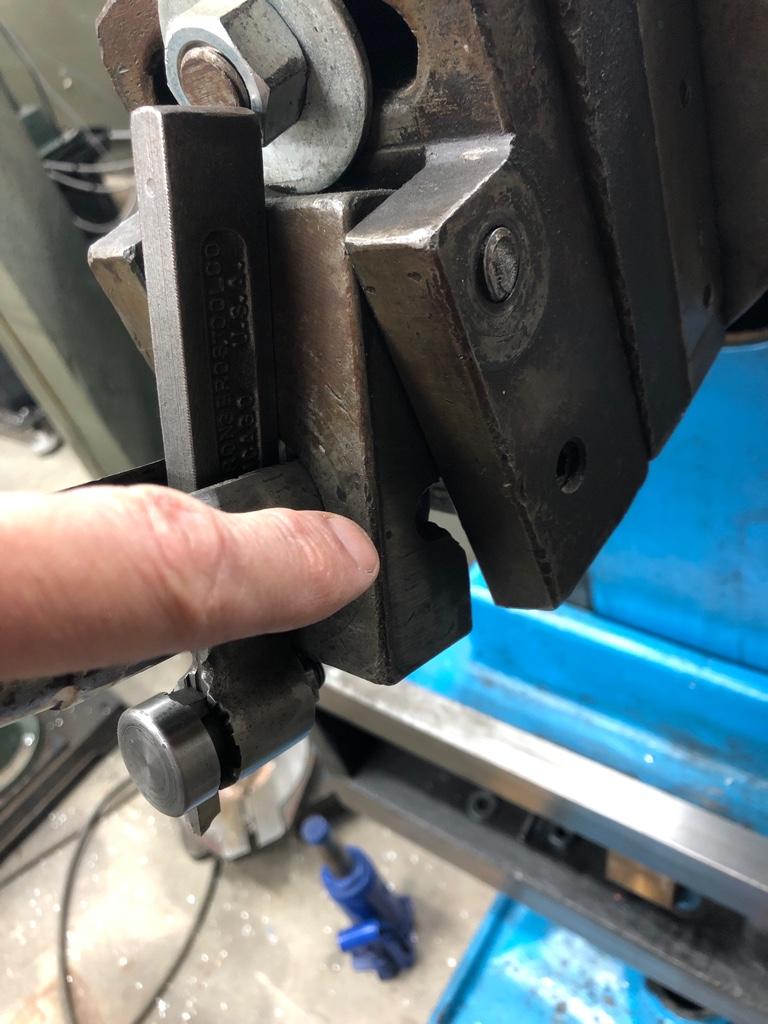

The clapper on the big shaper had a hole for a locking bolt on the clapper but the casting was blown out on the clapper box

Sent from my iPhone using Tapatalk

Here is the clapper

And on the big shaper, the boring bars I got with it were all homemade, and welded solid

The clapper on the big shaper had a hole for a locking bolt on the clapper but the casting was blown out on the clapper box

Sent from my iPhone using Tapatalk