Getting back to parallels…

My 1/4” ones showed up yesterday. UPS Standard shipping from Eastvale, CA (yes, it was free shipping & no UPS “dinger fees/extra charges” - not sure how they do that…)

After cleaning them (and a light stoning of the sharp edges), decided to break out some measuring tools to see how “good” they are.

These are the tools I used. One is a Swiss Made Etalon 0-1” tenths mic and the other is a Made in England Moore & Wright 1-2” tenths mic. The 1” gage block is an 0 grade Mitutoyo (for reference). I also used a 50 millionths Starrett Dial Master held in a Compaq (Geneve) instrument stand.

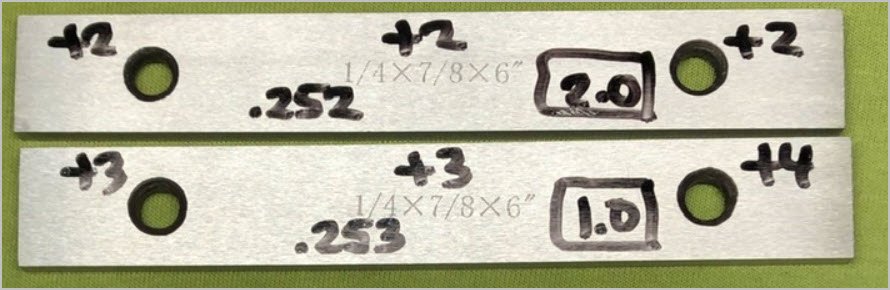

And here are the results. All measurements are in 1/10000 inches except for the thickness (it starts with the period and is in thousands of an inch and is the approximate average thickness). The three numbers across the top are deviations from the nominal height of the parallel using a tenths mic to measure in three spots. The boxed number is the “swept” value across 6” using the Dial Master on the Mitutoyo Grade A surface plate.

There is one “outlier” in the set: it is the top of the 7/8” ones. It has a very, very light bow in it. This was confirmed by a “hinge” test on the surface plate and the fact that the center is 2 tenths higher than the ends even though measuring the height shows no deviation along its 6” length (other than that it is 2 tenths over nominal of 0.875”.

Both 3/4” ones also have a minuscule bow in them.

So, are they good parallels? I would say so. I think they are within their claimed +/- 0.0002 (4 tenths TIR) tolerance of parallel over 6”.

NOTE: I am NOT sponsored by the vendor / manufacturer to promote them. I paid full price. I did this as “a fun afternoon project” because I was curious myself of how ”good” they are. Now I know.

My 1/4” ones showed up yesterday. UPS Standard shipping from Eastvale, CA (yes, it was free shipping & no UPS “dinger fees/extra charges” - not sure how they do that…)

After cleaning them (and a light stoning of the sharp edges), decided to break out some measuring tools to see how “good” they are.

These are the tools I used. One is a Swiss Made Etalon 0-1” tenths mic and the other is a Made in England Moore & Wright 1-2” tenths mic. The 1” gage block is an 0 grade Mitutoyo (for reference). I also used a 50 millionths Starrett Dial Master held in a Compaq (Geneve) instrument stand.

And here are the results. All measurements are in 1/10000 inches except for the thickness (it starts with the period and is in thousands of an inch and is the approximate average thickness). The three numbers across the top are deviations from the nominal height of the parallel using a tenths mic to measure in three spots. The boxed number is the “swept” value across 6” using the Dial Master on the Mitutoyo Grade A surface plate.

There is one “outlier” in the set: it is the top of the 7/8” ones. It has a very, very light bow in it. This was confirmed by a “hinge” test on the surface plate and the fact that the center is 2 tenths higher than the ends even though measuring the height shows no deviation along its 6” length (other than that it is 2 tenths over nominal of 0.875”.

Both 3/4” ones also have a minuscule bow in them.

So, are they good parallels? I would say so. I think they are within their claimed +/- 0.0002 (4 tenths TIR) tolerance of parallel over 6”.

NOTE: I am NOT sponsored by the vendor / manufacturer to promote them. I paid full price. I did this as “a fun afternoon project” because I was curious myself of how ”good” they are. Now I know.