To clear that up i was only pointing out that tool manufactures often exadurate the speeds and feeds of there tools. This is because there is a real arms race between the big companys that sell cutting tools.Alex scoffed at their performance numbers

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Ontario GTA West area meetup is planned for Saturday April 26th at Greasemonkeys shop in Aylmer Ontario. If you are interested and haven’t signed up yet, click here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pallets of 4140

- Thread starter Alexander

- Start date

Bofobo

M,Mizera(BOFOBO)

Attachments

I lament that it is not mine, but it is quite the horse, I was rushed so I did not take measurements, in short it would take a log for sure

Great test Mike thanks for doing that. That works out to about 6 square inches per minute. Hands down faster. Fastest setting Mike- any sfm measure there ?

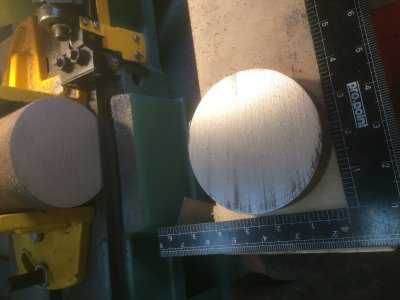

I managed 12 minutes with my new used 7x12 on 4" round. No coolant and trying not to wreck the blade. Slowest rpm setting. That's about 1 square inch a minute.

@John Conroy care to weigh in here?

Btw everybody Lenox has an interesting bandsaw blade guide along with detailed information on how to break in a blade. Basically start with a greatly reduced feed rate and gently start increasing it over many cuts. Otherwise risk the blade performance and life.

Other good stuff too.

http://www.lenoxtools.com/Guides/LENOX Guide to Band Sawing.pdf

Attachments

Janger your time for the 4" round is about the same as mine. I'm going to increase the blade speed next time as there was almost no heat last time. I'm using the factory blade which is 8 tpi and probably not the best quality. I have a Starrett blade but I'm going to keep that till the original is worn out.

For large surface area cuts you need to have a very aggressive blade to cut effectively. I think the idea is to have 3 teeth engaged at any given time to really get through the material at a reasonable rate. The next problem is how much horsepower you have to overcome the downforce that you apply. On big industrial saws they have a lot of horsepower which allows for high down feed pressure and better faster material removal. I personally put extra weight on my saw to get a decent cut time, but it's a bit of a pain to balance the blade tension, amount of weight to put on the saw and not stall the motor.

It's tiny and it does run that risk but yes I want to increase the cutting pressures. The most dangerous thing is the blade hopping and then slamming back onto the workpiece which will destroy the blade instantly if it grabs, industrial saws are either pneumatic or hydraulic to apply constant pressure and prevent the saw from being able to jump.

Again this ends up being a trade between the material, download pressure and horsepower. I personally don't see any issue running a saw to almost the motor stall point from down pressure on small saws, if my saw were 5hp I would not do it but on the smaller saws with no actual down feed pressure other than the weight of it, it speeds the cut stops rubbing and prevent to the saw from bouncing. I'm not saying this will give you the best blade life, it could potentially though, but if I lose 10 percent off the life but I can cut twice as fast I'm willing to take that trade off. The rubbing I would think would be the most likely thing to dull the bade, like running a lathe tool rubbing on a workpiece that is rotating your just hurting it.

Again this ends up being a trade between the material, download pressure and horsepower. I personally don't see any issue running a saw to almost the motor stall point from down pressure on small saws, if my saw were 5hp I would not do it but on the smaller saws with no actual down feed pressure other than the weight of it, it speeds the cut stops rubbing and prevent to the saw from bouncing. I'm not saying this will give you the best blade life, it could potentially though, but if I lose 10 percent off the life but I can cut twice as fast I'm willing to take that trade off. The rubbing I would think would be the most likely thing to dull the bade, like running a lathe tool rubbing on a workpiece that is rotating your just hurting it.

Bofobo

M,Mizera(BOFOBO)

My maximum round cut is stickered on my pro point as 3-3/8" It's basically a corded portable with a base. All blades is where I found a replacement running 6-10 but online everyone used more teeth per inch like the princess auto discontinued oem for this saw. Custom sized next day delivery from Edmonton.

Dogpounder

Member

HI all still looking for a long piece of the 6.75 x 2 ID. The seller wont return my emails or calls so must have sold it all. If anyone wants to part with some could we negotiate a price? Thanks

Dogpounder

Member

There was a 39" piece on a list I saw, maybe nobody got any of the 2"id stuff. I have a friend in Wyoming who want it for a cannon barrel. Ill ask him if he can bore it out. If you have a piece that long let me know. Thanks