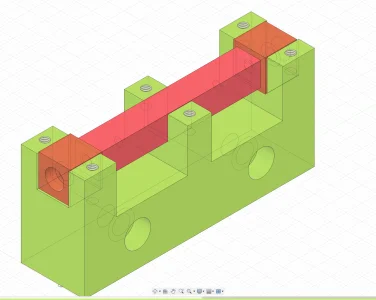

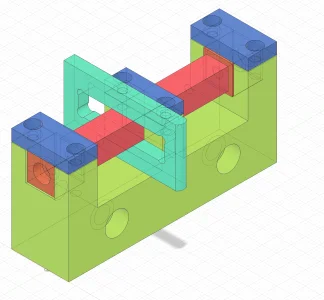

One bolt seems like a good idea - I was thinking twisting forces with one bolt might be a problem with the red bar trying to rotate on it's axis. Probably over worrying that as the fingers should hold it tight.I think you only need one through bolt. If the bolt goes all the way through from one side to the other, it will pull both orange blocks together simultaneously against the center block. You can use a bigger bolt that way and only have to tighten once.

Btw, I'm still thinking you don't really need that square clamping system. Just take up the backlash and go ..... 😉

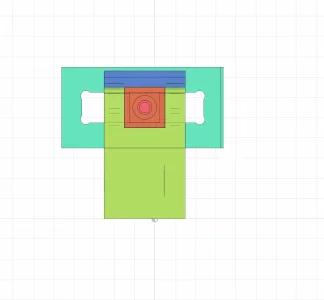

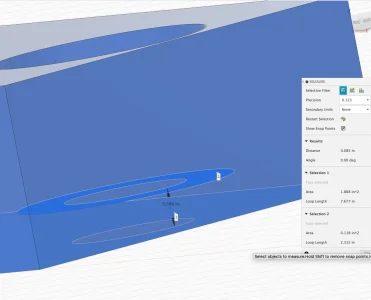

For the square clamping system it may not be needed - but I need to mill those square holes. The middle column one is especially tricky. Need a 4" reach through the side square 1x1" hole down to the middle column. So instead if I have top clamps then it will be easy to mill the square hole from the top of the vise jaw.

Last edited: