For next time, I've got a stash of various size woodruff keys. Not all sizes but quite a few. They came from an auction lot a couple of years ago.

Will do! And much appreciated.

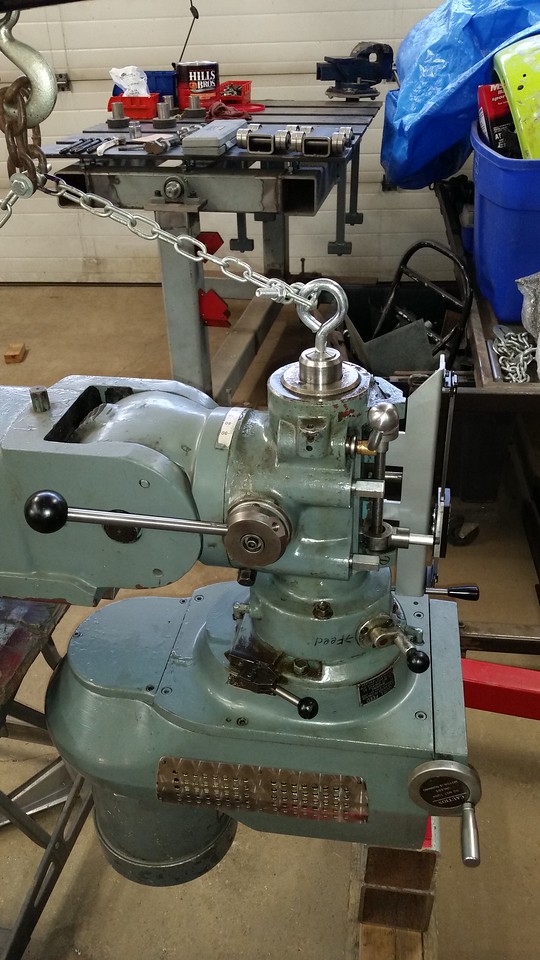

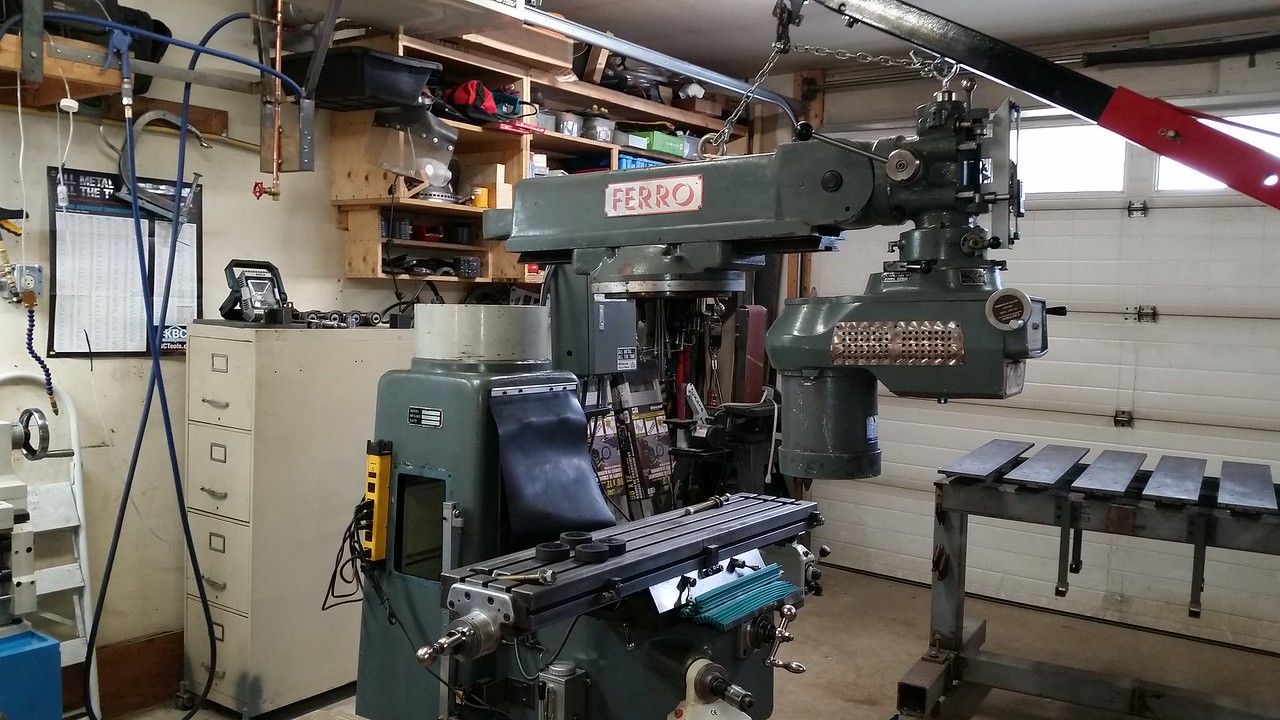

Maybe if I decide the keep the BP instead of the Hartford, I'll replace the home made key with a proper one. If I do that, I'll be in touch.

Thanks!

Anybody know if there are any special metal requirements for woodruff keys? Hardness, metal type, etc? In other words, is my home made key doomed to fail because it's made from plain cold rolled 1/4" plate?