AXA is a company: AXA-Entwicklungs-und Maschinenbau GmbH (www.axa-maschinenbau.de) If you go to the either of the websites I mentioned and they will have a PDF catalogue. If you go to the Stahlhalter24.de there is a blue box at the bottom right where you can get the brouchure. They have 8 different sizes that will accomodate tool bit sizes from 6mm to 63mm.Hey @thestelster,

Your holder is labelled AXA a d you seem to refer to that like AXA is a company.

But given that AXA, BXA, CXA, etc are also common sizes of toolposts, I can't help but wonder if there is a connection there. What size equivalent are those holders of yours? Are they like the AXA many guys on here have or are they much bigger? They look MUCH MUCH MUCH bigger!

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

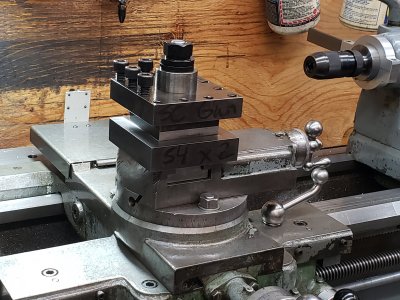

New Project - AXA Multifix

- Thread starter thestelster

- Start date

I've never found an article or description of who started the ABCD sizing designation/standard. I've read it was Aloris & they had patents in the 50's & expired. Anyways I think its mostly N-Am-centric thing? The big names like Aloris & Dorian have had it for a long time. To complicate matters, I'm not sure if the copycats have truly adopted the dimensions &/or mechanism universally. So yeah, 'AXA' is just coincidental that they both refer to lathe toolholders.

VicHobbyGuy

Ultra Member

When I looked at the Multifix info from those German sites, I found it strange that the toolholders are "sized" by lathe power (kW/H.P.) and tool size.

Yesterday I drilled & tapped the compound, drilled and counterbored the t-plate. Milled and then surface ground both as a unit. I just have to drill and ream the top plate for 10mm dowel pins. I'll be getting the pins and reamer today. All is looking pretty good.

Attachments

No no no no no no no! Now you have to be like the rest of us and let it sit for 6 months looking pretty.Drilled and reamed the t-plate, 10mm anti-rotation dowel pin installed. Set up a number of tools to center height. Now to use it!

Making a split bushing for the Multifix boring bar holder. 40mm OD, 1" ID, 130mm in length. Making it out of Uddeholm Ramax HH stainless, pre-hardened to 340HB. I'll hone the bore and slit it tomorrow.

Attachments

Even used more than one tool holder. Congrats.Making a split bushing for the Multifix boring bar holder. 40mm OD, 1" ID, 130mm in length. Making it out of Uddeholm Ramax HH stainless, pre-hardened to 340HB. I'll hone the bore and slit it tomorrow.

Making a split bushing for the Multifix boring bar holder. 40mm OD, 1" ID, 130mm in length. Making it out of Uddeholm Ramax HH stainless, pre-hardened to 340HB. I'll hone the bore and slit it tomorrow.

Yup! First job for every tool should be to make another tool for the tool........ LOL!

Looks great Stelster!

I have to open the bore of the bushing by about 0.0015" to accept 1" tools. Tool post grinder won't go that deep, and the Sunnen hones I have only go up to around 0.800", so I have to use the brake hone.

I'm kind of interested in this, more for model engine cylinders. Do you mean you have a Sunnen hone machine & tooling but for that particular diameter is somehow depth limited? Or is it some other kind of Sunnen honing tool that is meant to be mounted similar to your (I'll call it a brake cylinder style hone) shown in your picture? Reason I ask is seems like model engineers that use the sprung, tri-stone type hones seem to always encounter bell-mouthing issues. On my radial I used brass Accu-lap, good control & finish but brutally laborious process to remove a thou.

Attachments

Hi Peter, have a look at this thread that I posted a little while ago https://canadianhobbymetalworkers.com/threads/honing-bores.5591/I'm kind of interested in this, more for model engine cylinders. Do you mean you have a Sunnen hone machine & tooling but for that particular diameter is somehow depth limited? Or is it some other kind of Sunnen honing tool that is meant to be mounted similar to your (I'll call it a brake cylinder style hone) shown in your picture? Reason I ask is seems like model engineers that use the sprung, tri-stone type hones seem to always encounter bell-mouthing issues. On my radial I used brass Accu-lap, good control & finish but brutally laborious process to remove a thou.

I also have the Sunnen Porta-Hones. But because I use the hones for shotgun barrels, the bore diameters I can hone is from about .5" - .8". Yes, those spring hones will generally follow and existing bore, even its crooked, and they can bell mouth. You just have to keep the whole stone within the bore, ant not coming partially out, if you get my drift.

Attachments

Machining the relief slot, and through cut. Suggested speed for this 3" slitting hss blade is 61 rpm. Lowest on the mill is 100rpm, so had to change the VFD from 60Hz to 36Hz. Checked it with my laser tach, and was at 55rpm, close enough.

Attachments

Houston, we have a problem.

After slitting, removing the burrs, and cleaning it up, it appears to have sprung about 0.002" closed. So now the bore is 0.998" and a 1" tool won't fit. Of course in the Uddelholm brochure for this metal says to stress relieve it after rough machining at 985°F for 2 hours.

So now to decide my options. Maybe just enlarge the bore? But the OD of the bushing is now 0.002" less than 40mm for the boring bar holder. But it probably has enough clamping movement for it to still grip the bushing.🙁

After slitting, removing the burrs, and cleaning it up, it appears to have sprung about 0.002" closed. So now the bore is 0.998" and a 1" tool won't fit. Of course in the Uddelholm brochure for this metal says to stress relieve it after rough machining at 985°F for 2 hours.

So now to decide my options. Maybe just enlarge the bore? But the OD of the bushing is now 0.002" less than 40mm for the boring bar holder. But it probably has enough clamping movement for it to still grip the bushing.🙁

Attachments

What if you press in a 1" ID shaft? Then bring it up to 985°F for 2 hours. Then press out the shaft. Can't hurt.Houston, we have a problem.

After slitting, removing the burrs, and cleaning it up, it appears to have sprung about 0.002" closed. So now the bore is 0.998" and a 1" tool won't fit. Of course in the Uddelholm brochure for this metal says to stress relieve it after rough machining at 985°F for 2 hours.

So now to decide my options. Maybe just enlarge the bore? But the OD of the bushing is now 0.002" less than 40mm for the boring bar holder. But it probably has enough clamping movement for it to still grip the bushing.🙁

Houston, we have a problem.

How much of the bushing is actually sprung? Could that part be Yielded?

Couldn't you just put a 1 inch bushing into it to stress relieve it?

Or how about a screw (or three) to push it apart as needed?

I don't have an oven to get to that temperature.What if you press in a 1" ID shaft? Then bring it up to 985°F for 2 hours. Then press out the shaft. Can't hurt.

A 1" shaft won't fit. I'm afraid that if I force it in, it might gall, and then you'll never separate them, or if you do, you'll end up damaging the interior of the bushing.How much of the bushing is actually sprung? Could that part be Yielded?

Couldn't you just put a 1 inch bushing into it to stress relieve it?

Or how about a screw (or three) to push it apart as needed?

I actually have a hydraulic dent raiser for shot gun bores. I can put a spacer in (shotgun bores are 0.730" (12g)) and give it a go.

I just measured the MT4 adapter bushing, and it is the same size as my new bushing, so the holder will clamp down enough to grip it.

Perhaps I just open up the bore so that it will hold the 1" tools and be done with it.

Perhaps I just open up the bore so that it will hold the 1" tools and be done with it.