OMG, haha, are we going to open up that can of worms again about headstock alignment, tail stock alignment, carriage and crosslide alignment 😉My tailstock has an MT3 Taper with the tang provisions so I am happy using it to drill with. It is also 4 inches, but not with a tang. The tang will self eject at 0.75 inches so I lose 3/4" of travel. It has never been an issue and even if it was, I love the auto eject feature so I'd simply live with it.

I have an MT3 tool holder that came with my lathe that I've never used. I will have to try it your way just to get a feel for your joy.

One of the concerns I would have with using a tool holder is concentricity to the spindle. It's easy to adjust side parallelism, but how do you adjust the vertical? Just pray that it's ok?

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Project - AXA Multifix

- Thread starter thestelster

- Start date

OMG, haha, are we going to open up that can of worms again about headstock alignment, tail stock alignment, carriage and crosslide alignment 😉

Nah, no worries. Just having fun! Then again, speaking of alignment, see My First Major DRO Job thread update:

First Major DRO Job

The Rego info is quite clear to me :) Is it becasue I am born in EU? Not sure. I didn't land on an individual product page. I landed on a generic info page for the entire collet set in a chart that was sort of like the LMS info. I can't seem to find it now.

canadianhobbymetalworkers.com

canadianhobbymetalworkers.com

OMG, haha, are we going to open up that can of worms again about headstock alignment, tail stock alignment, carriage and crosslide alignment 😉

Having had fun with it, I think I need to get serious.

I mounted my Southbend Keyless chuck in my MT3 toolholder and checked the alignment.......

It was horrible. Much much worse than I expected.

Using a short piece of 3/8 dowel, it was just under 10 thou over 1 inch. 28 thou over 3 inches - oddly high at the tip, not low. Much as I know that drills and reamers follow the hole, I don't personally feel like 30 thou over the length of a normal drilled hole is a good thing. At a minimum, it's likely to result in a conical hole.

I think it would be worth measuring yours @thestelster. Might save you wondering what happened on some future job.

Now my original question haunts me. How do I adjust that out? Or should I bother?

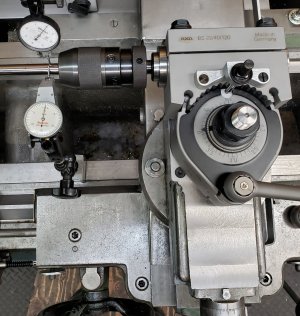

I just did some testing for this set up.

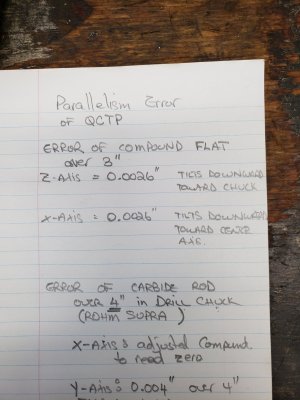

Firstly, when I was doing the installation of the Multifix QCTP, I surface ground the top of the compound slide.

As you can see the error in parallelism is 0.0026" over 3" in the z-axis, tilted downwards towards the headstock.

Firstly, when I was doing the installation of the Multifix QCTP, I surface ground the top of the compound slide.

As you can see the error in parallelism is 0.0026" over 3" in the z-axis, tilted downwards towards the headstock.

Attachments

I then put the drill chuck (Rohm Supra) onto the Multifix and chucked a 6" carbide rod. I rotated the compound so that I had zero deviation in the x-axis over 4". And measured the parallelism error in the y-axis: 0.004" over 4", tipped downwards toward the headstock. I think that's pretty good all things considered, and the versatility of drilling with the QCTP far outweighs the slight error in parallelism. After all its just to drill holes. If I need greater accuracy I will be boring.

Attachments

I then put the drill chuck (Rohm Supra) onto the Multifix and chucked a 6" carbide rod. I rotated the compound so that I had zero deviation in the x-axis over 4". And measured the parallelism error in the y-axis: 0.004" over 4", tipped downwards toward the headstock. I think that's pretty good all things considered, and the versatility of drilling with the QCTP far outweighs the slight error in parallelism. After all its just to drill holes. If I need greater accuracy I will be boring.

Wish mine was that good. So going back to my original question, how would you correct for that?

Shim the Tool Post?

I think first is to measure the top of the compound that the QCTP is sitting on, and see how it correlates with your readings off the chucked rod.Wish mine was that good. So going back to my original question, how would you correct for that?

Shim the Tool Post?

Compound is only 0.0015 off over its full length of 7 inches. I'm not gunna try to change that. I think it's all in the tool post. I might try my piston style toolpost. But there is a limit to how much work I want to do to be able to use a toolpost mounted chuck. I'll prolly try a shim on the back edge though.

Ok, check this out!! I decided to rotate the compound slide 90° so that it would be in the same position that I surface ground it. Zeroed the x-axis, and now the vertical deviation is 0.001" over 4"!!! Now, I almost never use the lathe in this position, so I think I will take the compound slide off and surface grind it in the position I usually have the compound (direction of travel along the z-axis.)

@thestelster - I put a 6 thou shim under the backside of my Toolpost. My vertical runout is now 1.5 thou over the length of the 3" rod. But it has a dip in it right at the chuck so I know it isn't really straight. It's the best I have right now though. I should get a few short non-tapered indicator rods. Regardless, the shim seems to work just fine. Again, I'm not grinding my compound.

Any chance the bed might also be worn ever so slightly?Here are a couple shots of the results.

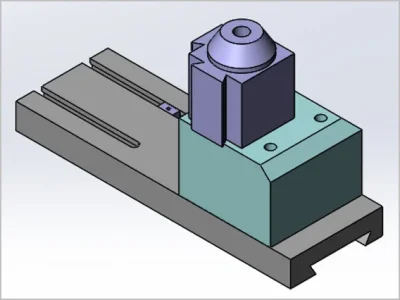

Maybe one day you will eliminate the middle man (compound) for a solid tool post. You have a much better quality, repeatable tool holder than most mortals & looks like a relatively rapid way of removing/installing. Of course when you need a compound you need a compound so that's kind of the pita aspect. But a solid TP is still on my to-do list for stability reasons.

Attachments

Any chance the bed might also be worn ever so slightly?

Not likely. My head alignment is awesome over the same range.

Someday soon I'll have time to work on my new alignment dumbbell design and hopefully extend the alignment to the majority of my bed. We will see.

Maybe one day you will eliminate the middle man (compound) for a solid tool post. You have a much better quality, repeatable tool holder than most mortals & looks like a relatively rapid way of removing/installing. Of course when you need a compound you need a compound so that's kind of the pita aspect. But a solid TP is still on my to-do list for stability reasons.

Mine too. But I'll be happy just making a special toolpost block just for parting. I plan to remove the entire quick-change toolpost to do that. I want a solid steel column between the bottom of the parting tool and the top of the compound. It's project #42 on my list...... LOL!

Hi Peter, I've thought about it, but I use the compound for a couple of operations. 1: I occasionally have to do a tapered cone at the entrance of a bore (actually rifle chamber), and 2: I use the compound for widening the root of screw threads. Most of my threading inserts are non-topping, so they are able to cut 36-12tpi. Their tip width is 0.006", which is great for very fine threads, but if I need to cut a 12tpi thread the root width for that 0.020", so I have to move the compound in the z-axis by 0.014" to achieve the proper pitch diameter. Different pitches have different root widths. Without a compound I would need to get topping inserts for almost every thread pitch I want to cut.Maybe one day you will eliminate the middle man (compound) for a solid tool post. You have a much better quality, repeatable tool holder than most mortals & looks like a relatively rapid way of removing/installing. Of course when you need a compound you need a compound so that's kind of the pita aspect. But a solid TP is still on my to-do list for stability reasons.

And other operations like dressing a center, making punches, change the compound angle slightly for clearance during boring, etc.

I want to build a solid toolpost riser - just because. It is in the C priority list....

Me too! Just because!

Truth is that I got parting working fairly well thanks to a donated parting tool from another member. It was too big for his lathe. But I'm still smarting over why it's so difficult. I have to try a solid riser - just because!

Too funny!